Combined tool for turning hexagonal prism type thin-walled aluminium part

A hexagonal prism and thin-walled technology, applied in the field of combined tooling, can solve the problems of low processing efficiency and slow speed, and achieve the effects of simple structure, convenient assembly and disassembly, and poor rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

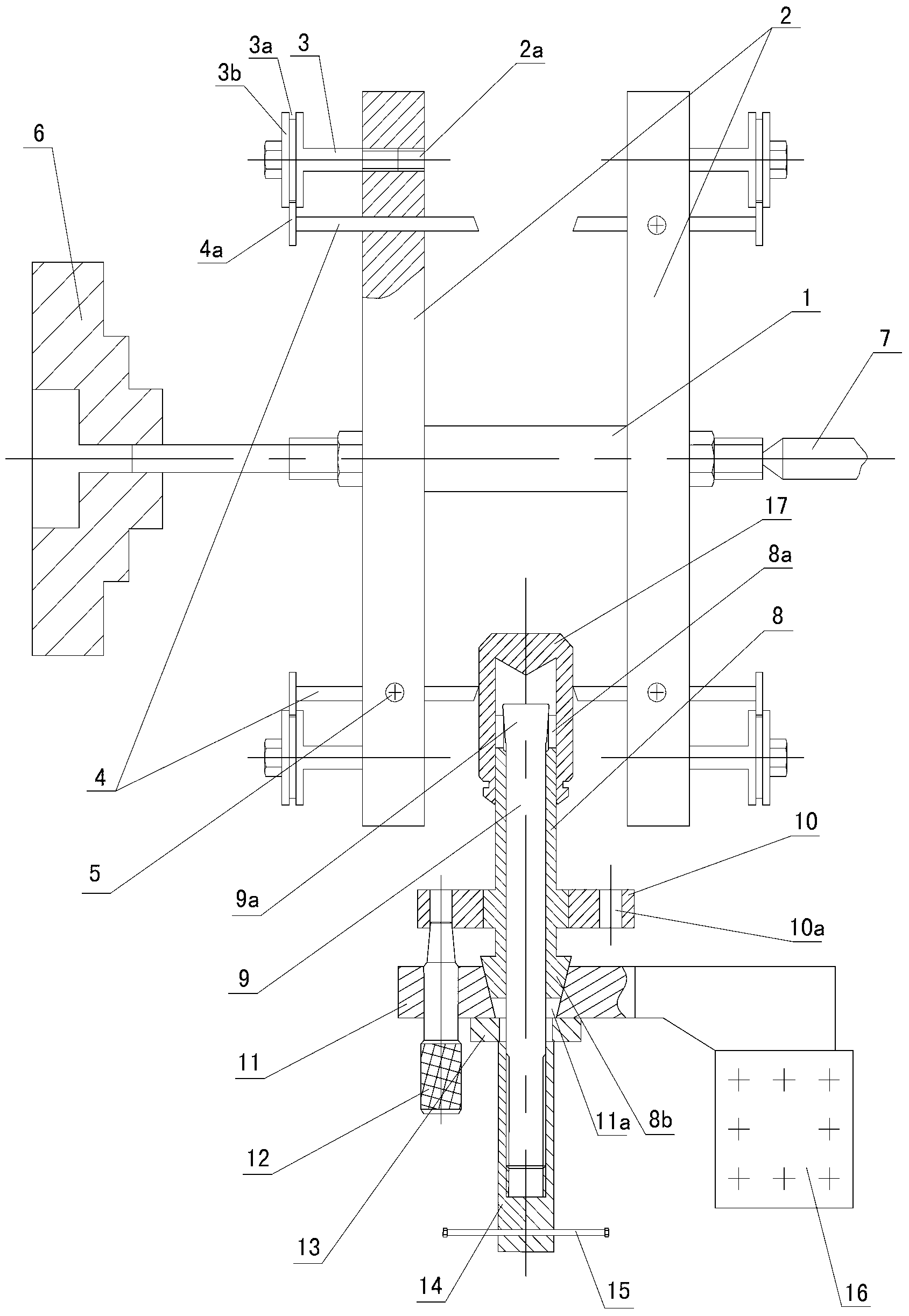

[0008] The present invention is further described below in conjunction with embodiment and accompanying drawing.

[0009] see attached image

[0010] The hexagonal prism-type thin-walled aluminum part turning tooling assembly provided by the present invention has tool tooling and workpiece tooling. The tool tooling has a mandrel 1, and a pair of relatively arranged cutter heads 2 are mounted on the mandrel 1, and the tools on the two cutter heads 2 are The cutter heads of 4 are oppositely arranged. In the cutter tooling of this embodiment, two cutters 4 are housed on each cutter head 2, one of which is a rough cutting cutter and the other is a fine cutting cutter, and the distance between the rough cutting cutter and the mandrel 4 is greater than that between the finish cutting cutter and the core. axis distance. Setting the two cutting tools as a rough cutting tool and a fine cutting tool respectively can realize one rough machining and one finish machining of the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com