Motion controlling method for middle support device in process of forming large-scale wind turbine blade

A technology for a support device and a wind turbine blade, applied in the mechanical field, can solve the problems of fixed support posture, time-consuming adjustment process, manual adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with the accompanying drawings.

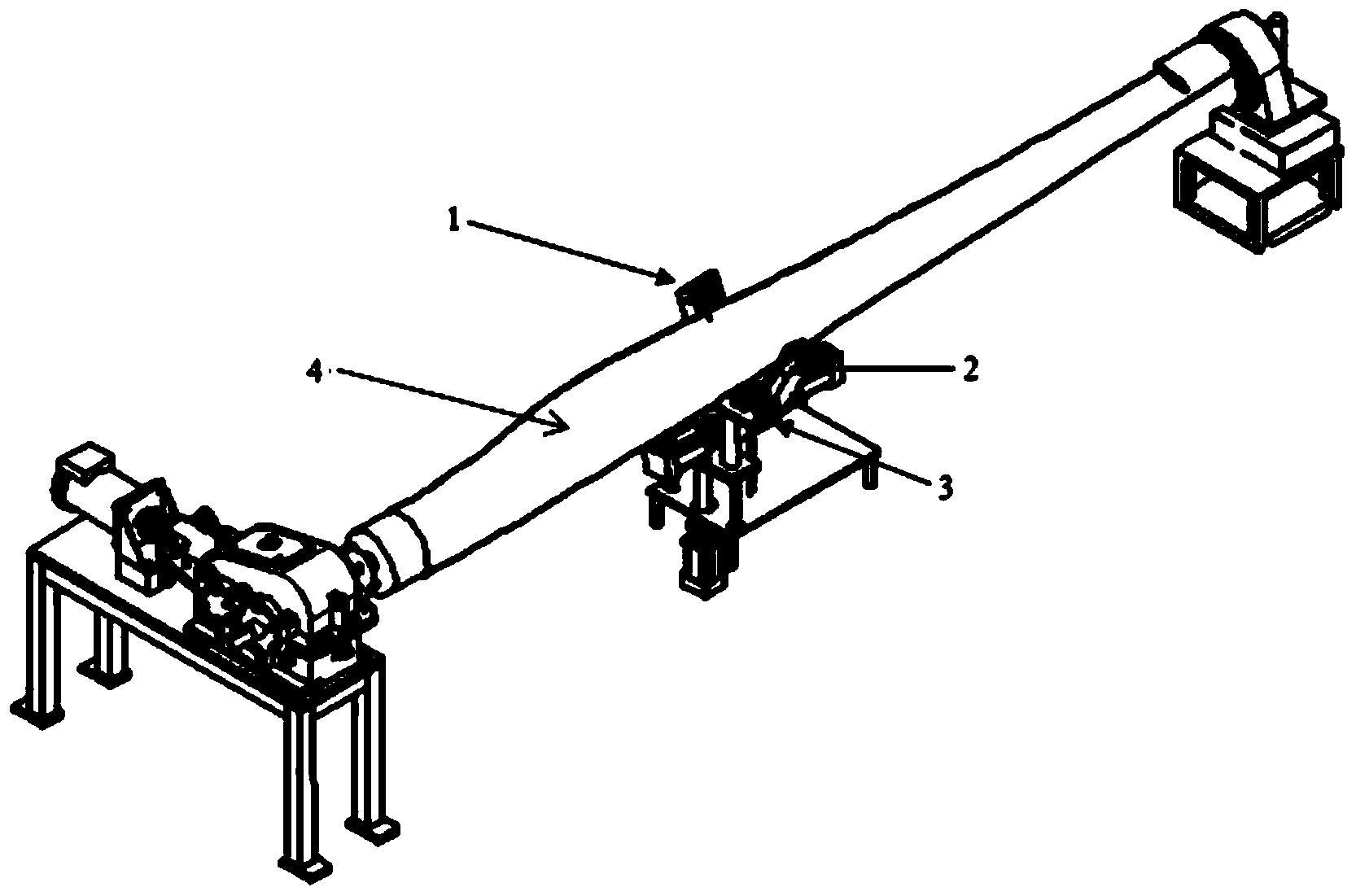

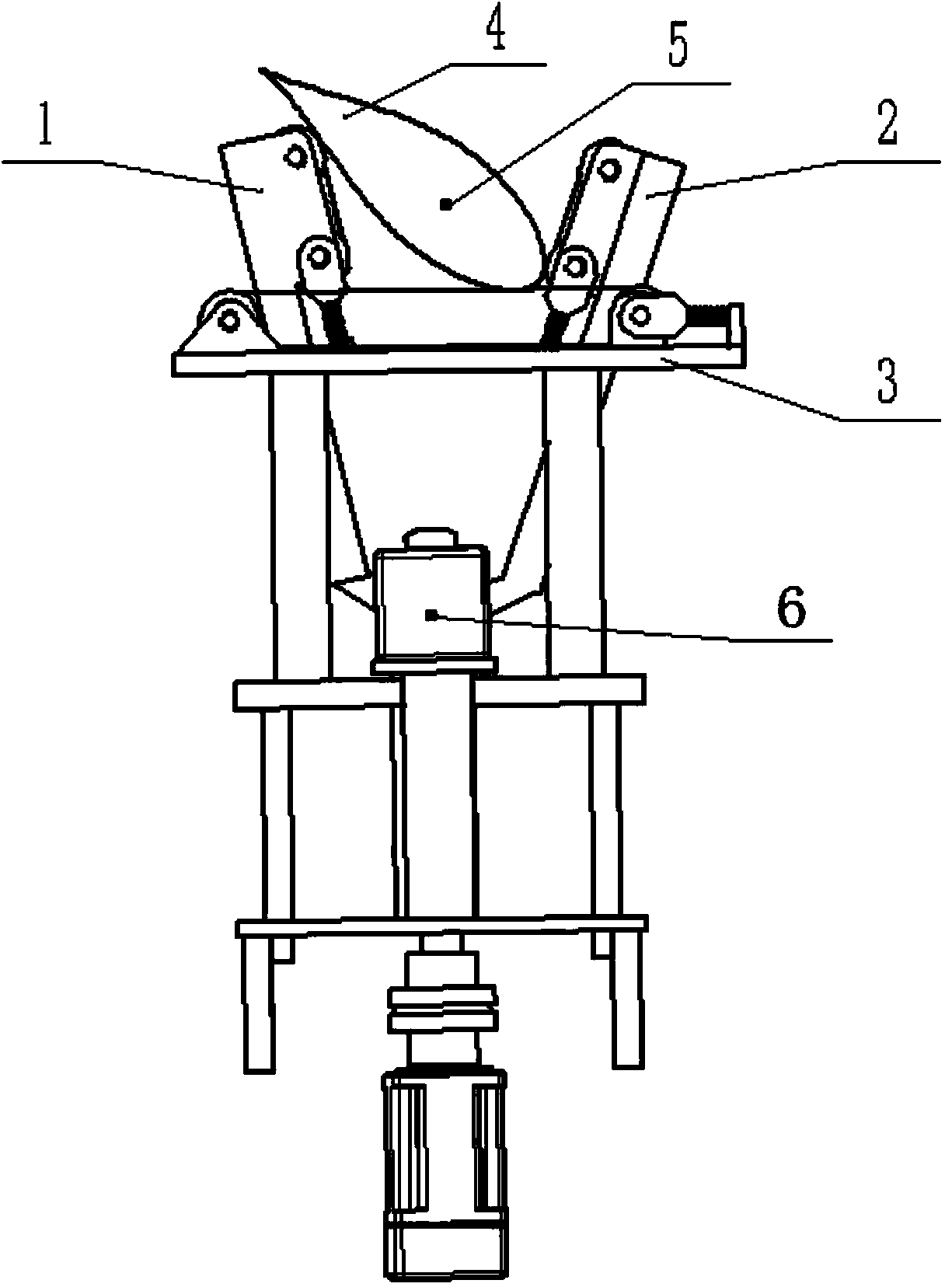

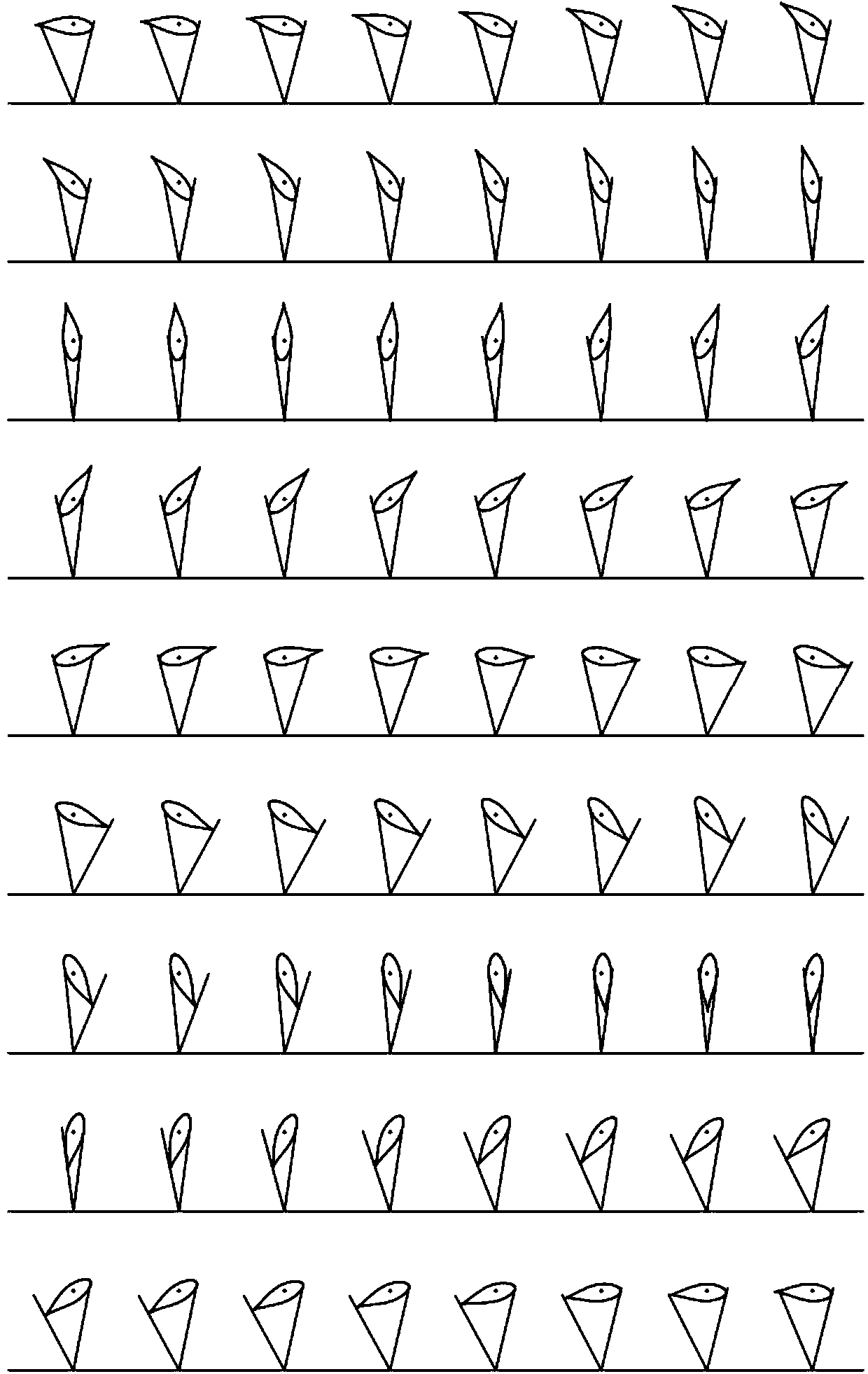

[0058] see Figure 1 to Figure 7 .

[0059] The invention relates to a motion control method for a middle support device in the forming process of a large-scale wind power blade, and the control method adopts a control mode combining an upper computer and a lower computer. see figure 1 , 2 As shown, the middle support device includes a left support plate 1 , a right support plate 2 and a middle support plate 3 . The upper computer is an industrial computer, and its function is to obtain the motion track data of the support plate by running the support track calculation program, that is, the corresponding swing position of the support plate when the blade rotates to each moment. At the same time, the upper computer transmits the obtained data to the lower computer before the blade starts to rotate. The lower computer adopts Trio 209 multi-axis motion cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com