Cold fabric

A fabric and cooling technology, applied in the direction of fabrics, knitting, textiles, etc., can solve the problems of no sweat absorption and deodorization, the cushion is easy to stink, and the adverse effects on human health, etc., to achieve good air permeability, slow heating, and good cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

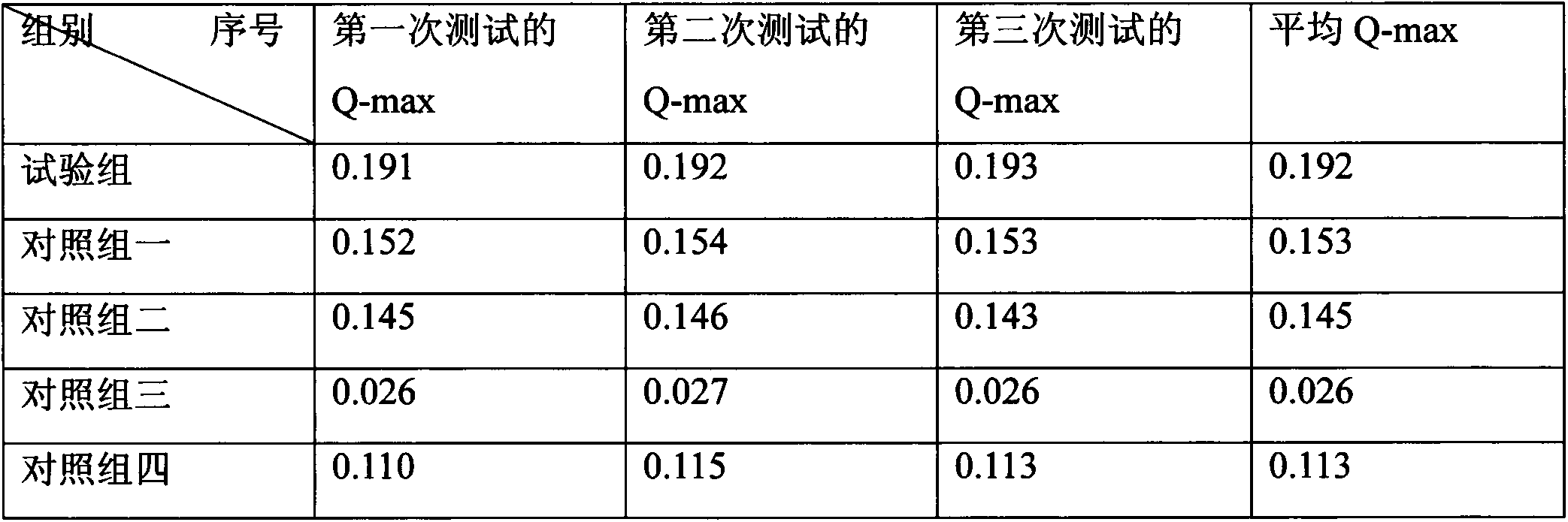

[0027] Embodiment 1: a kind of cool fabric, and this fabric is woven together by ultra-high molecular weight polyethylene fiber and polyester fiber. The cooling fabric adopts a weft knitting method, wherein the ratio of ultra-high molecular weight polyethylene fibers to polyester fibers in the cooling fabric is 7:3.

Embodiment 2

[0028] Embodiment 2: a kind of cool fabric, and this fabric is to be woven together by ultra-high molecular weight polyethylene fiber and polyester fiber. The cooling fabric is a knitted fabric using a warp knitting method, wherein the ratio of the amount of ultra-high molecular weight polyethylene fibers to polyester fibers in the cooling fabric is 6:4.

Embodiment 3

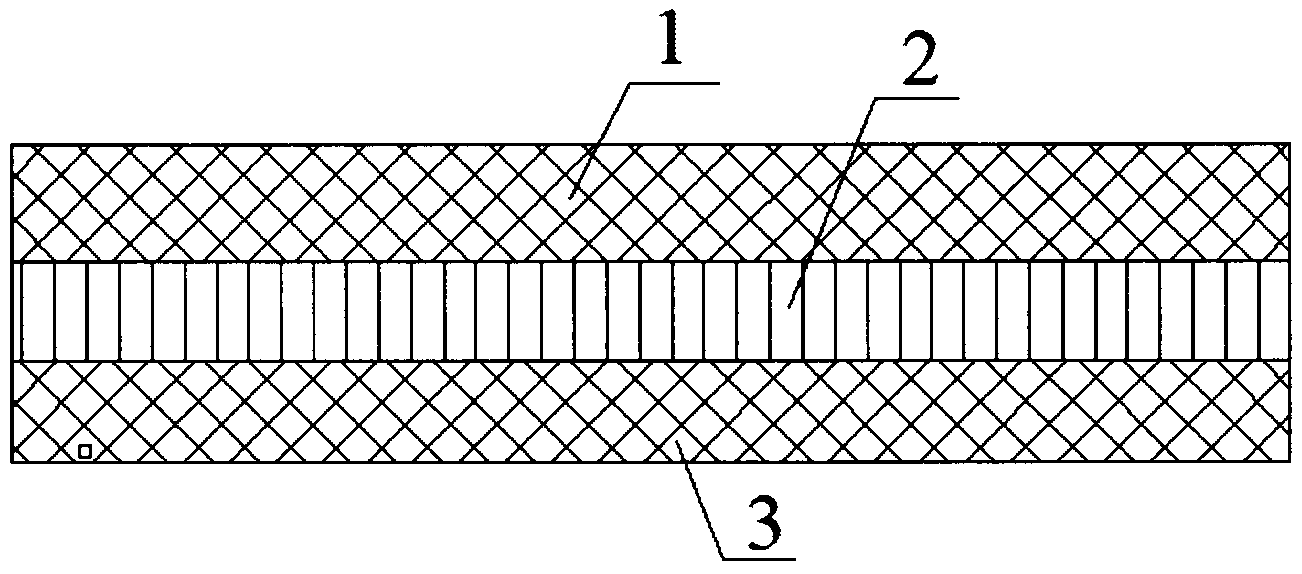

[0029] Example 3: Please see figure 1 , a cooling fabric, the cooling fabric is a three-dimensional structure, including three layers, the three layers are respectively: the upper layer 1, the middle layer 2, the lower layer 3, the upper layer 1 and the lower layer 3 both contain ultra-high molecular weight polyethylene fibers; the middle layer Layer 2 connects the upper layer 1 and the lower layer 3 into one; the amount of ultra-high molecular weight polyethylene fibers in the upper layer 1 is 50% of the total amount of fibers in the upper layer 1 by mass percentage, and the amount of ultra-high molecular weight polyethylene fibers in the lower layer 3 The amount is 50% of the total amount of fibers in the lower layer 3 in terms of mass percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com