High-pressure rubber hose and production process thereof

A high-pressure hose and production process technology, applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc., can solve the problems of no self-lubrication, no impact resistance, low tensile strength, etc., and achieve excellent impact resistance strength, Excellent corrosion resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

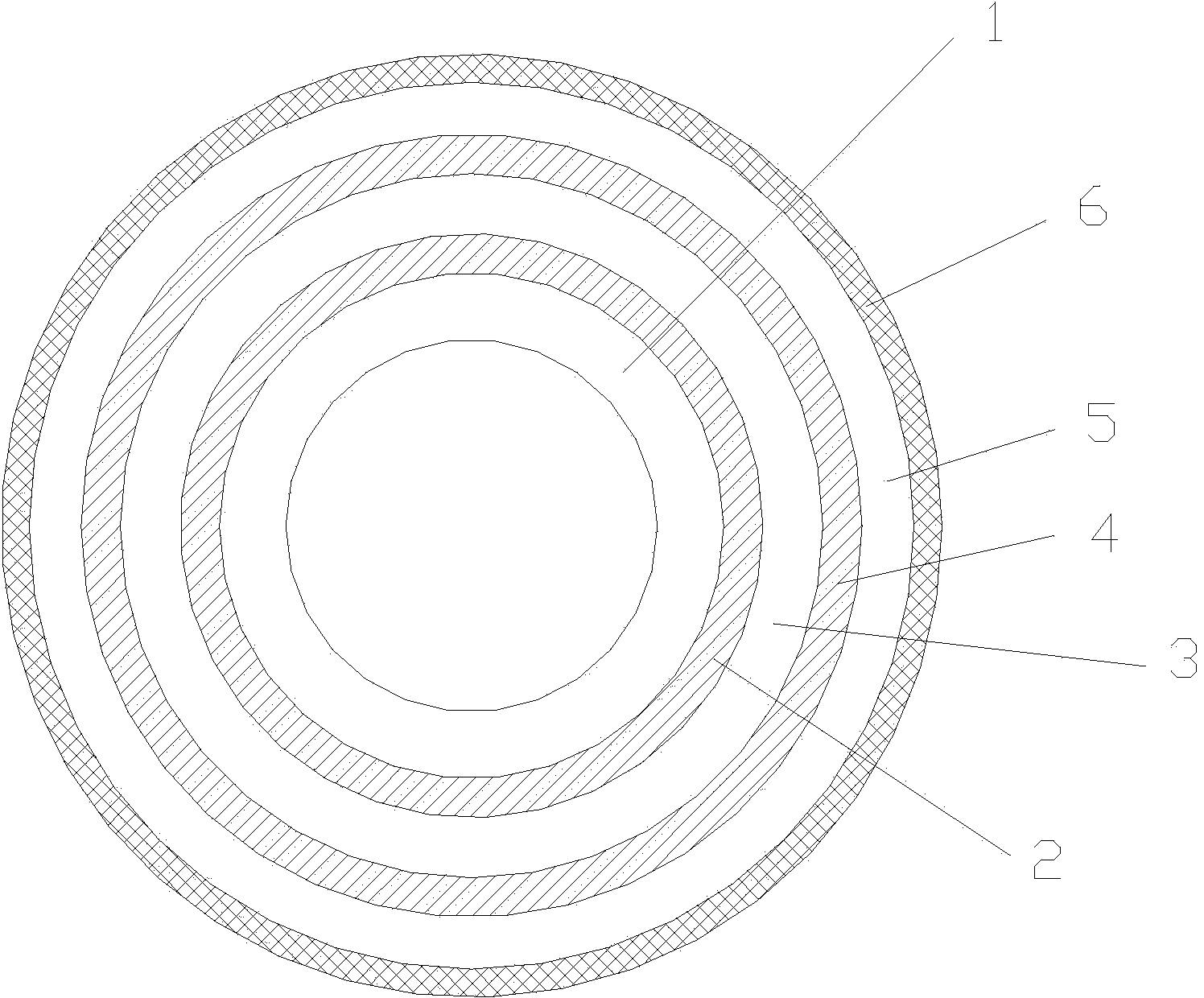

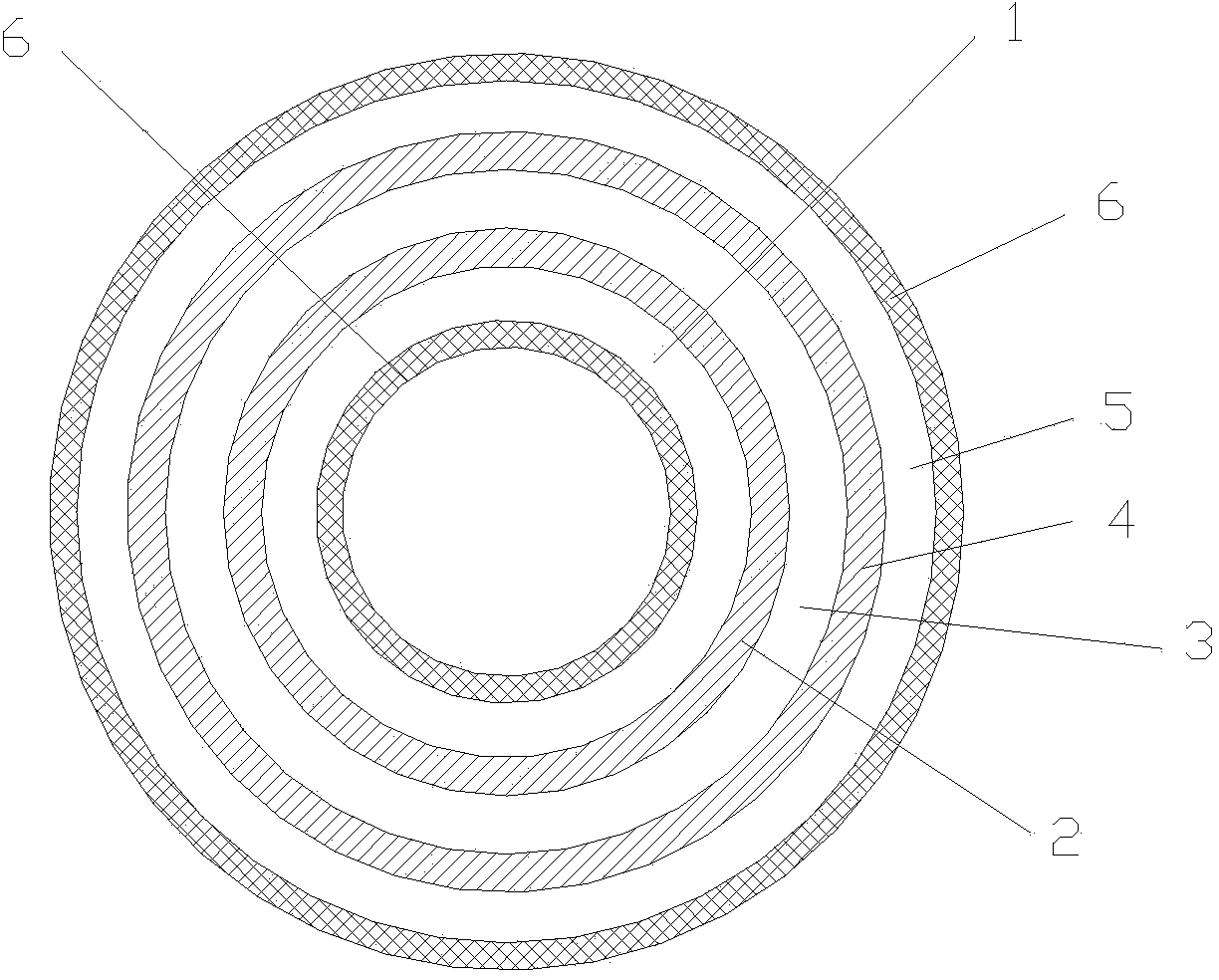

[0058] The high-pressure hose is composed of inner rubber layer 1, first steel wire layer 2, middle rubber layer 3, second steel wire layer 4, outer rubber layer 5, and ultra-high molecular weight polyethylene film 6 from the inside to the outside. The components of layer 5 are: 100 parts by weight of ethylene propylene rubber, 5 parts by weight of zinc oxide, 1 part by weight of stearic acid, 60 parts by weight of carbon black N330, 20 parts by weight of dibutyl ester, 0.5 parts by weight of Dimethylaminoethyl methacrylate, 1.5 parts by weight of accelerator TMTD and 1.5 parts by weight of sulfur.

Embodiment 2

[0060] The high-pressure hose is composed of inner rubber layer 1, first steel wire layer 2, middle rubber layer 3, second steel wire layer 4, outer rubber layer 5, and ultra-high molecular weight polyethylene film 6 from the inside to the outside. The components of layer 5 are: 100 parts by weight of ethylene propylene rubber, 5 parts by weight of zinc oxide, 1 part by weight of stearic acid, 60 parts by weight of carbon black N330, 22 parts by weight of dibutyl ester, 0.5 parts by weight of Dimethylaminoethyl methacrylate, 1.5 parts by weight of accelerator TMTD and 1.5 parts by weight of sulfur.

Embodiment 3

[0062] The high-pressure hose is composed of inner rubber layer 1, first steel wire layer 2, middle rubber layer 3, second steel wire layer 4, outer rubber layer 5, and ultra-high molecular weight polyethylene film 6 from the inside to the outside. The components of layer 5 are: 95 parts by weight of ethylene propylene rubber, 5 parts by weight of zinc oxide, 0.95 parts by weight of stearic acid, 60 parts by weight of carbon black N550, 21 parts by weight of dibutyl ester, 0.5 parts by weight of Dimethylaminoethyl methacrylate, 1.5 parts by weight of accelerator TMTD and 1.5 parts by weight of sulfur.

[0063] The middle rubber layer 3 used in the present invention is the existing ordinary middle rubber layer 3. In addition to the composition of the inner rubber layer 1 and the outer rubber layer 5 being different from the prior art, the production method can be manufactured by the existing high-pressure hose production process.

[0064] The present invention also provides a produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com