Reinforced skateboard and production thereof

A sliding board and reinforced technology, which is applied to skis, chemical instruments and methods, skis, etc., can solve the problems of high production cost of sliding boards, complicated production of sliding boards, and weak bonding of boards, etc., and achieve overall strength and hardness. The effect of lifting, reducing weight and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

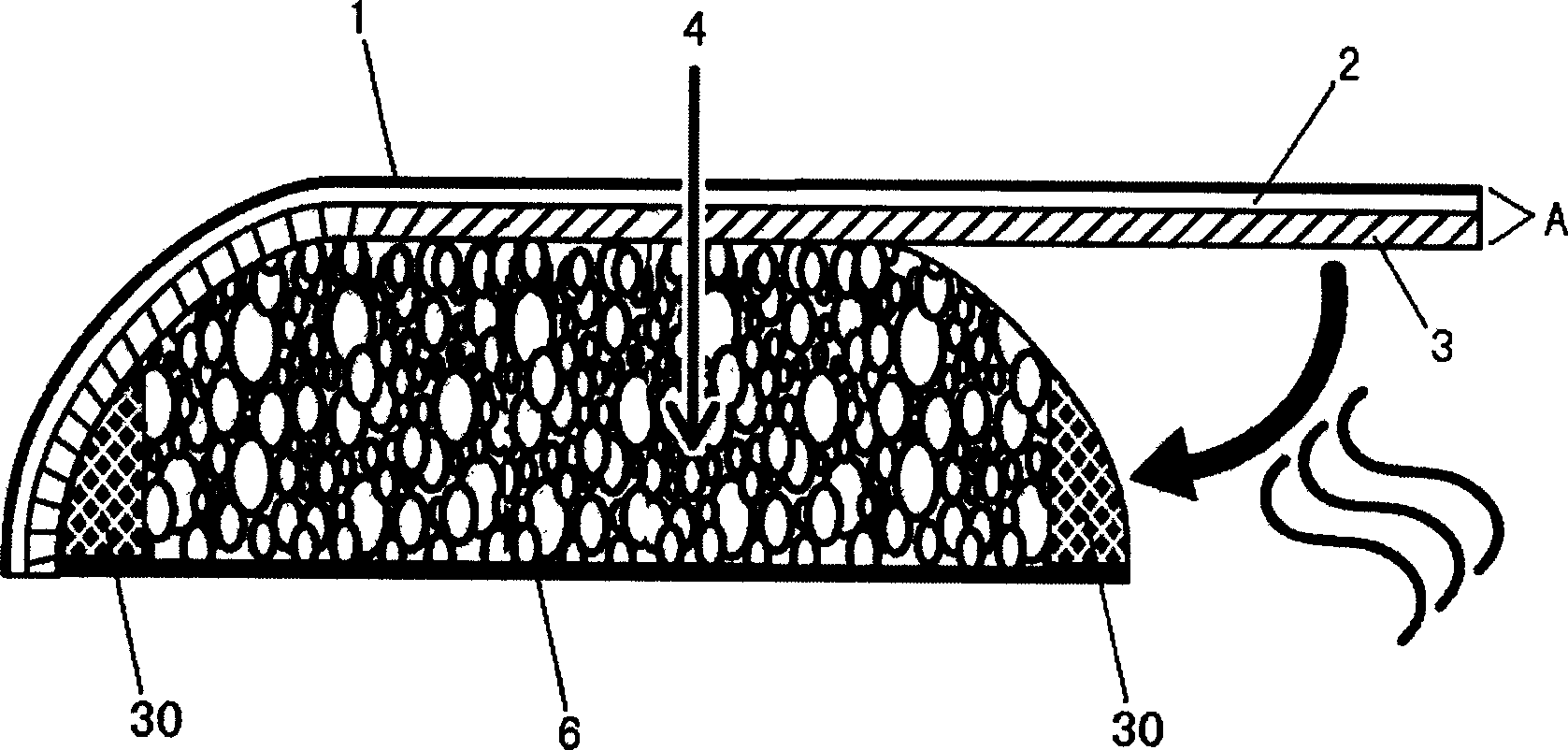

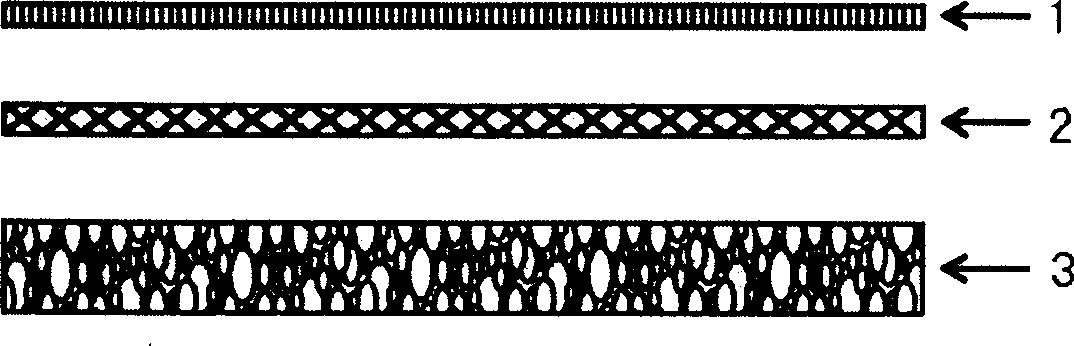

[0031] figure 1 and figure 2 Shows the front view of the snowboard embodiment of the present invention and the cross-sectional structure of the board. The snowboard includes a core board 4, panels that are respectively arranged on the upper and lower sides of the core board 4, and a PE solid board 6 with a low coefficient of friction. . Panel A includes a patterned printed film 1 and a foamed upper liner 3, and a layer of novel ultra-low-density metallocene (Metallocen Catalysced) adhesive is arranged between the printed film 1 and the upper foamed liner 3. Adhesive film 2 (such as image 3 shown). A high-density reinforcement wrapping 30 is also provided between the panel A and the surrounding sides of the core board 4 . In this embodiment, the core board 4 is made of a layer of polyethylene (PE) plastic foam board with a density of 1.5 to 4 lbs / cubic foot and a thickness of 26 mm. The foamed upper liner 3 also adopts PE plastic foamed sheet material, and its density is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com