Preparation method of ultra-high molecular weight polyethylene fiber

An ultra-high molecular weight, polyethylene fiber technology, applied in the direction of single-component polyolefin rayon, fiber processing, spinning solution preparation, etc., can solve the problems of decreased strength, very large influence, unfavorable fibers, etc., and achieve mechanical properties. Lifting, improving mechanical properties, enhancing the effect of stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

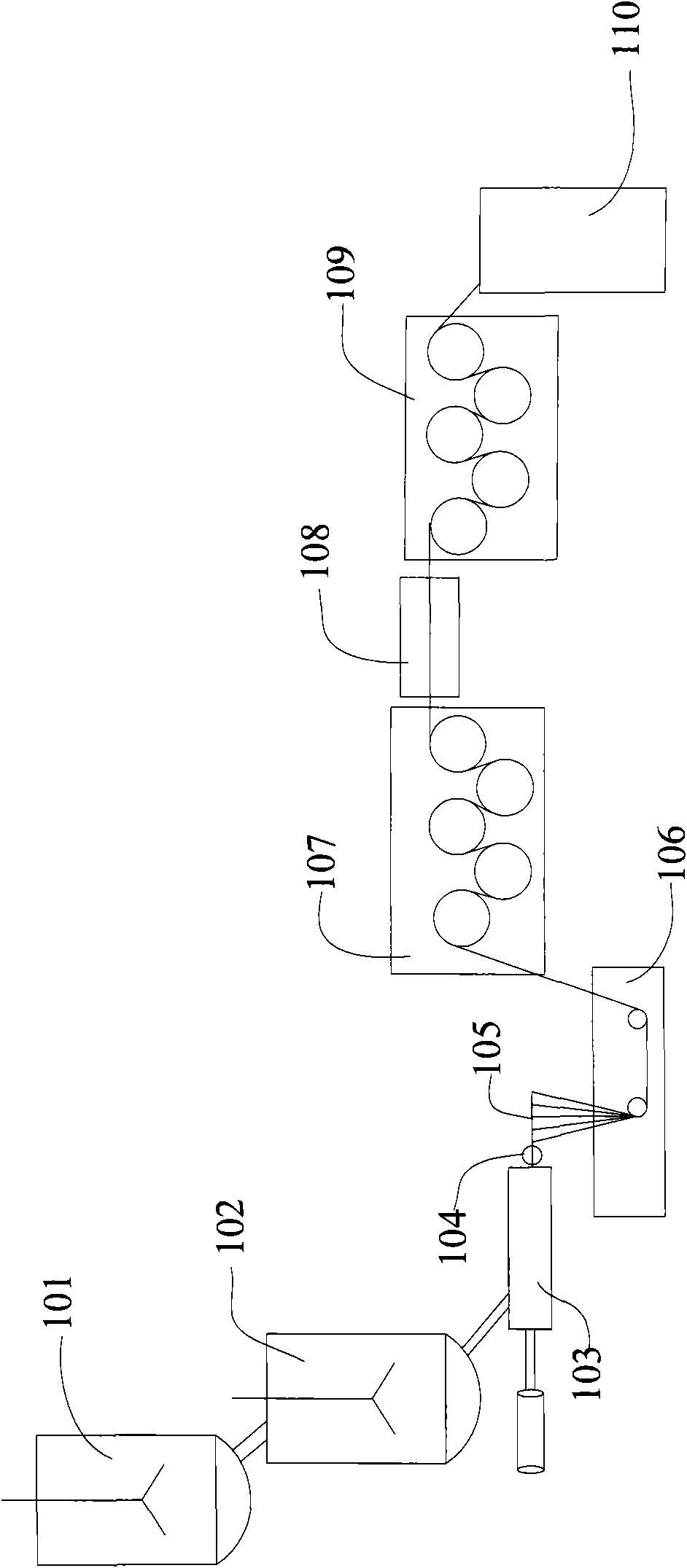

[0032] The invention provides a method for preparing ultra-high molecular weight polyethylene fibers, comprising the following steps:

[0033] a) Mix ultra-high molecular weight polyethylene powder with a solvent to obtain a suspension after swelling, and then extrude and dissolve through a twin-screw extruder to obtain a spinning solution with a concentration of 4% to 25%. The solvent is liquid at room temperature hydrocarbons;

[0034] b) Spinning and cooling the spinning solution to obtain jelly filaments;

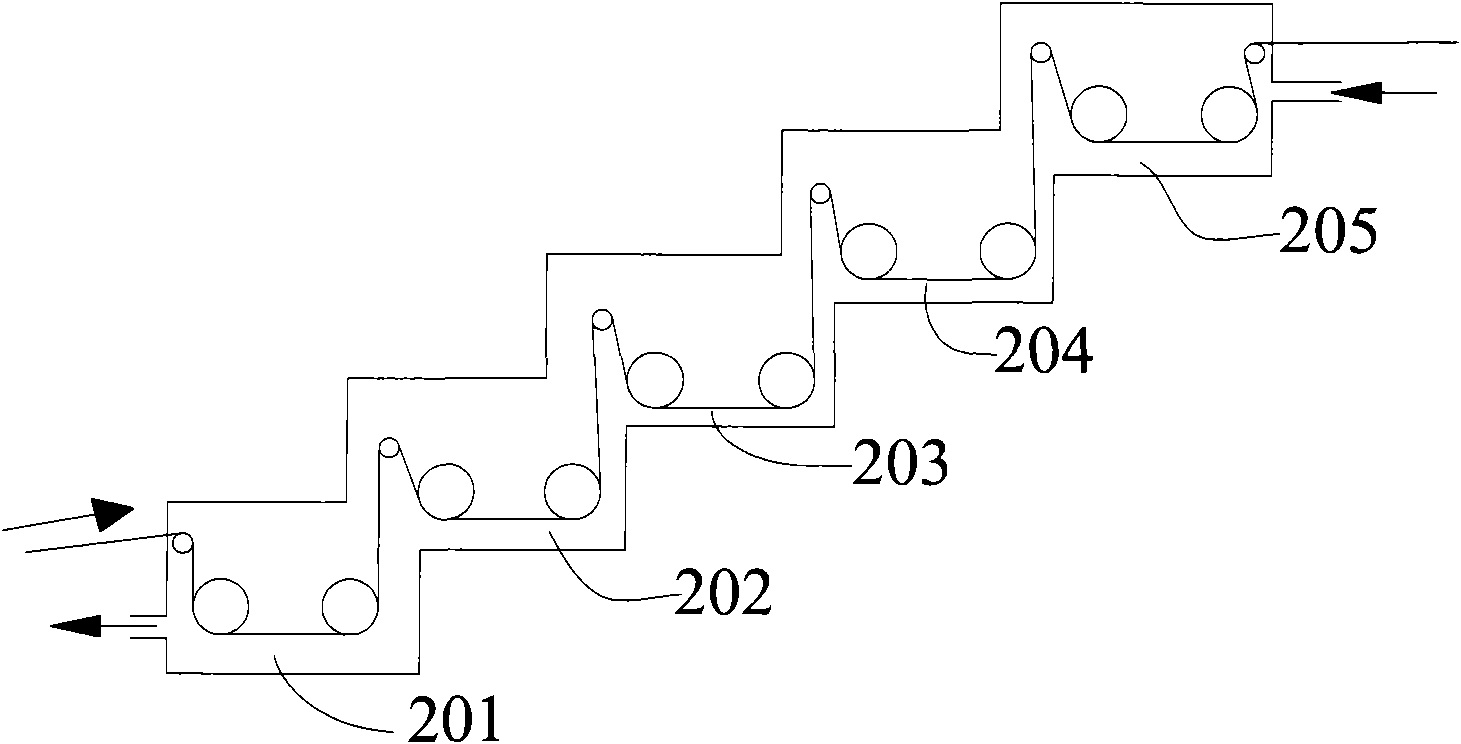

[0035] c) applying 1-10 times pre-stretching to the jelly filaments, leaving the pre-stretched jelly filaments to stand for 12-48 hours, then extracting and drying;

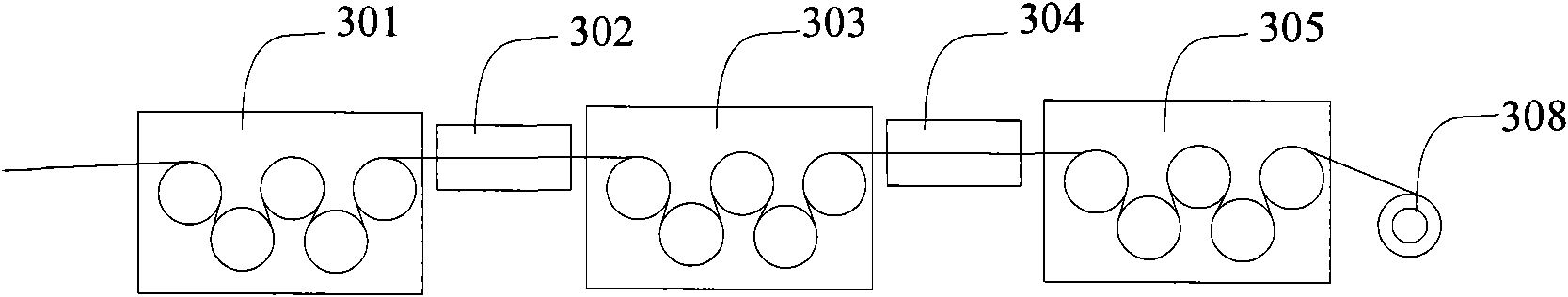

[0036] d) applying 4 times to 130 times of hot drawing to the dried jelly filaments in the temperature range of 70° C. to 160° C. to obtain ultra-high molecular weight polyethylene fibers.

[0037] In order to achieve the purpose of the present invention, the ultra-high molecular weight polyethylene powd...

Embodiment 1

[0072] Put 80kg of ultra-high molecular weight polyethylene powder and 920kg of paraffin oil into the swelling kettle 101 and stir and swell for 40 minutes at a temperature of 105° C. to obtain a suspension.

[0073] The obtained suspension is sent into the storage tank 102 and cooled to 25°C, and then sent into the twin-screw extruder 103 for extrusion and dissolution. Among them, the inlet temperature of the twin-screw extruder is 100°C, the intermediate temperature is 185°C, and the outlet temperature is 225°C, the suspension stays in the twin-screw extruder for 5 minutes, and the rotation speed of the twin-screw extruder It is 180rpm (rotation / minute). The suspension is extruded and dissolved by a twin-screw extruder, and the macromolecules are unwound to make a transparent jelly spinning solution.

[0074] The jelly spinning solution is extruded at a spinning speed of 1m / min through a metering pump 104, a spinneret with 400 holes (the spinneret diameter is 0.8mm, and the...

Embodiment 6

[0081] In this embodiment, 100 kg of ultra-high molecular weight polyethylene powder and 900 kg of paraffin oil were placed in the swelling kettle 101 and stirred and swelled for 45 minutes at a temperature of 108° C. to obtain a suspension.

[0082] The obtained suspension is sent into the storage tank 102 to cool to 25° C. and then sent to the twin-screw extruder 103 for extrusion and dissolution. Wherein, the inlet temperature of the twin-screw extruder is 105°C, the intermediate temperature is 190°C, and the outlet temperature is 220°C, the residence time of the suspension in the twin-screw extruder is 5 minutes, and the rotation speed of the twin-screw extruder is 200rpm. The suspension is extruded and dissolved by a twin-screw extruder, and the macromolecules are unwound to make a transparent jelly spinning solution.

[0083] According to the same spinning process as in Example 1, jelly filaments were prepared.

[0084] The prepared jelly yarn is passed through a tunne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Powder size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com