Mold-locking head plate of injection molding machine

An injection molding machine and mold clamping technology, applied in the field of injection molding equipment, can solve the problems of increasing the amount of manufacturing template materials and processing costs, unable to solve the contradiction between template performance and manufacturing cost, affecting the dimensional accuracy of injection molding products, etc., to improve rigidity, vibration, etc. Small, rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific embodiments.

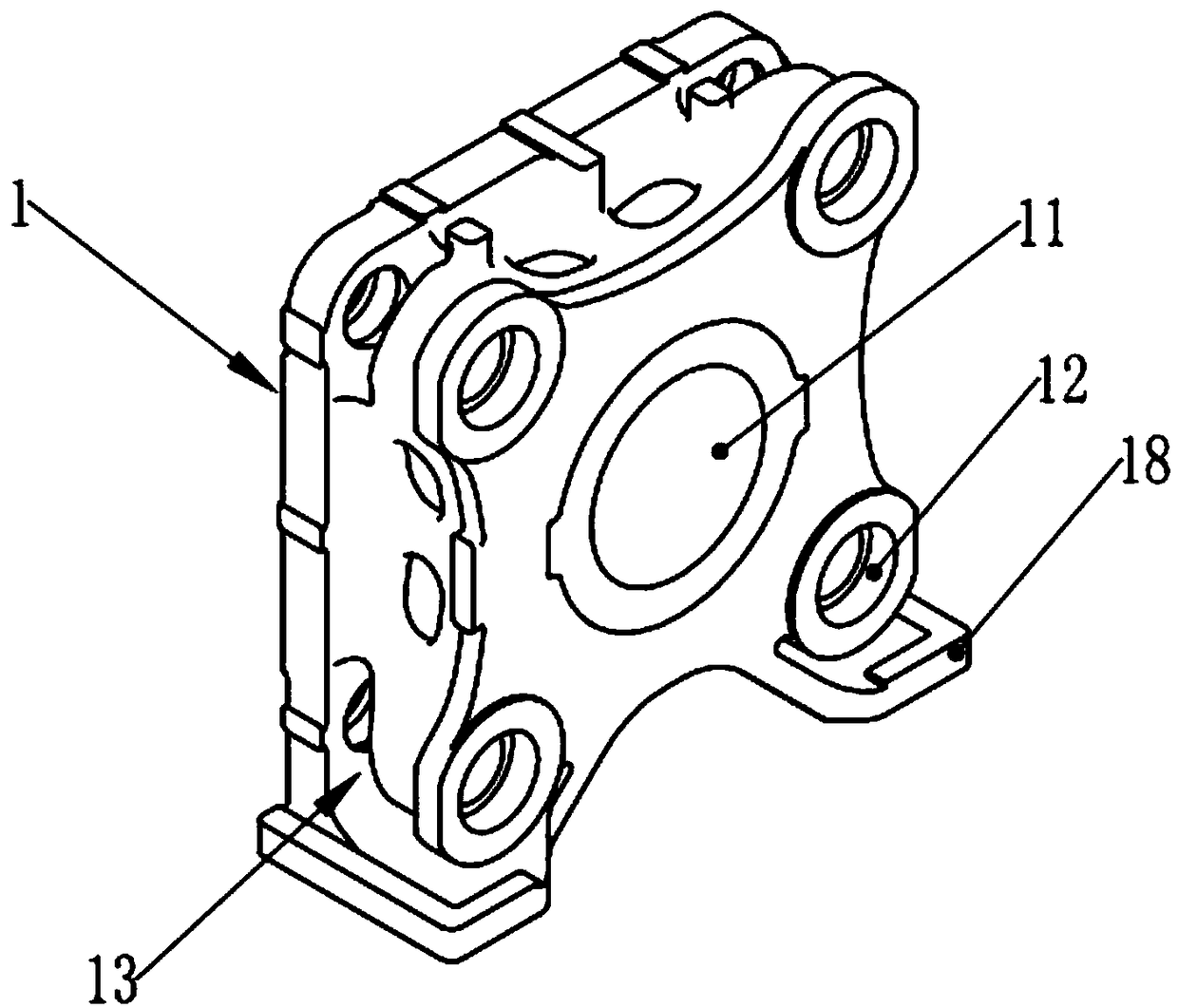

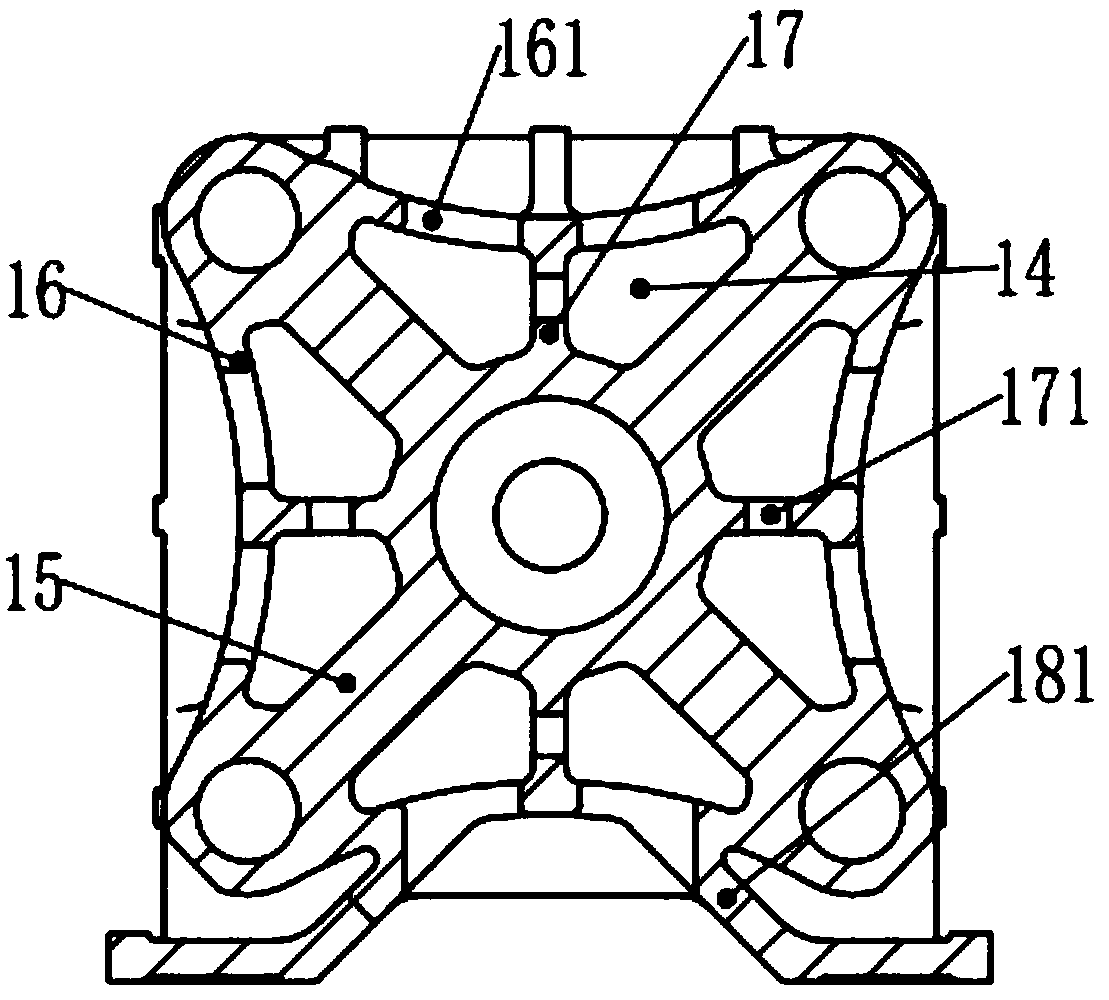

[0035] Such as Figure 1 to Figure 5 , comprising a main body 1, each of the four corners of the main body 1 is provided with a guide post mounting hole 12, each side of the four corners of the main body 1 is provided with an unloading groove 13, and the unloading groove 13 is connected with the guide post mounting hole 12 through, the unloading groove 13 is narrowed from the notch to the bottom of the groove.

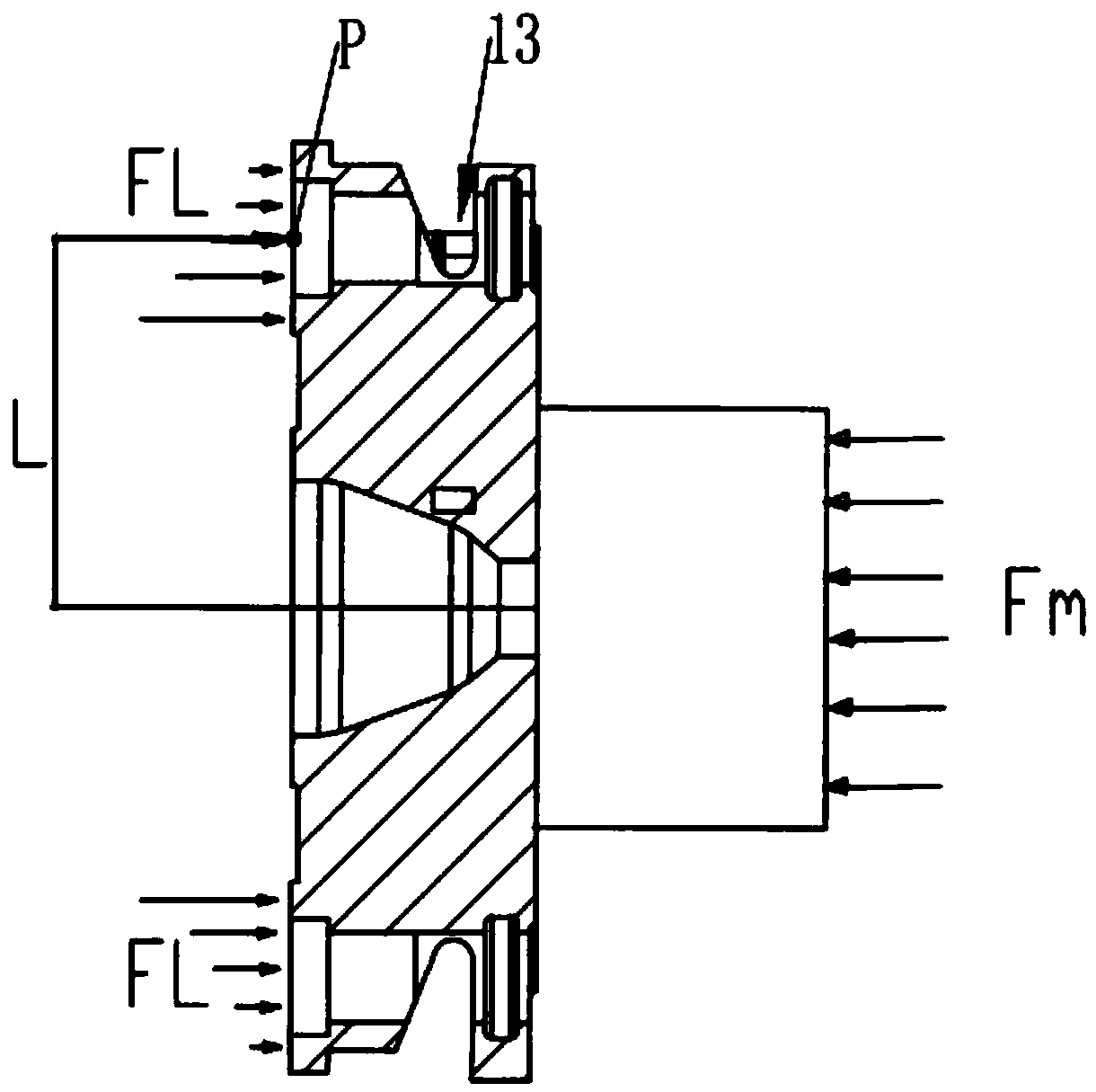

[0036] The guide post installation hole 12 is used to install the guide post. During the mold clamping process, the resultant force of the four guide posts to the pulling force FL of the body 1 and the mold clamping force Fm form a group of balanced forces. When the body 1 is subjected to the mold clamping force Fm, the guide post The post installation hole 12 will receive the pulling force FL of the guide post to the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com