Special horizontal type shaking table for cooling and sterilizing process for protein preparation

A protein, horizontal technology, applied in the field of protein liquid cooling and sterilization process and its special horizontal shaker, can solve the problems of power, amplitude, frequency, temperature and time that are difficult to meet the requirements of large industrial applications, and can solve the problem of coagulation. Agglomeration and denaturation, improve sterilization efficiency, and ensure the effect of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

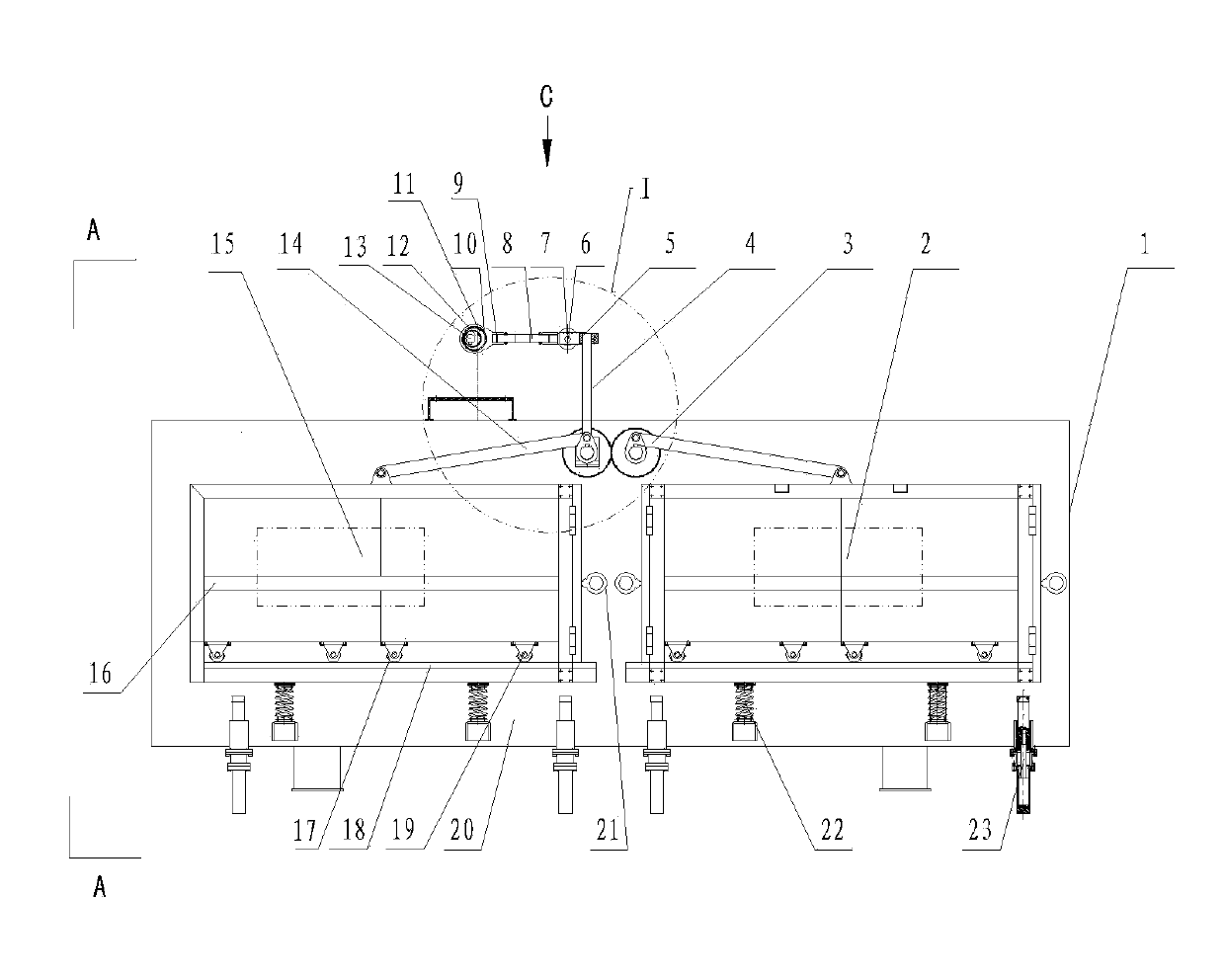

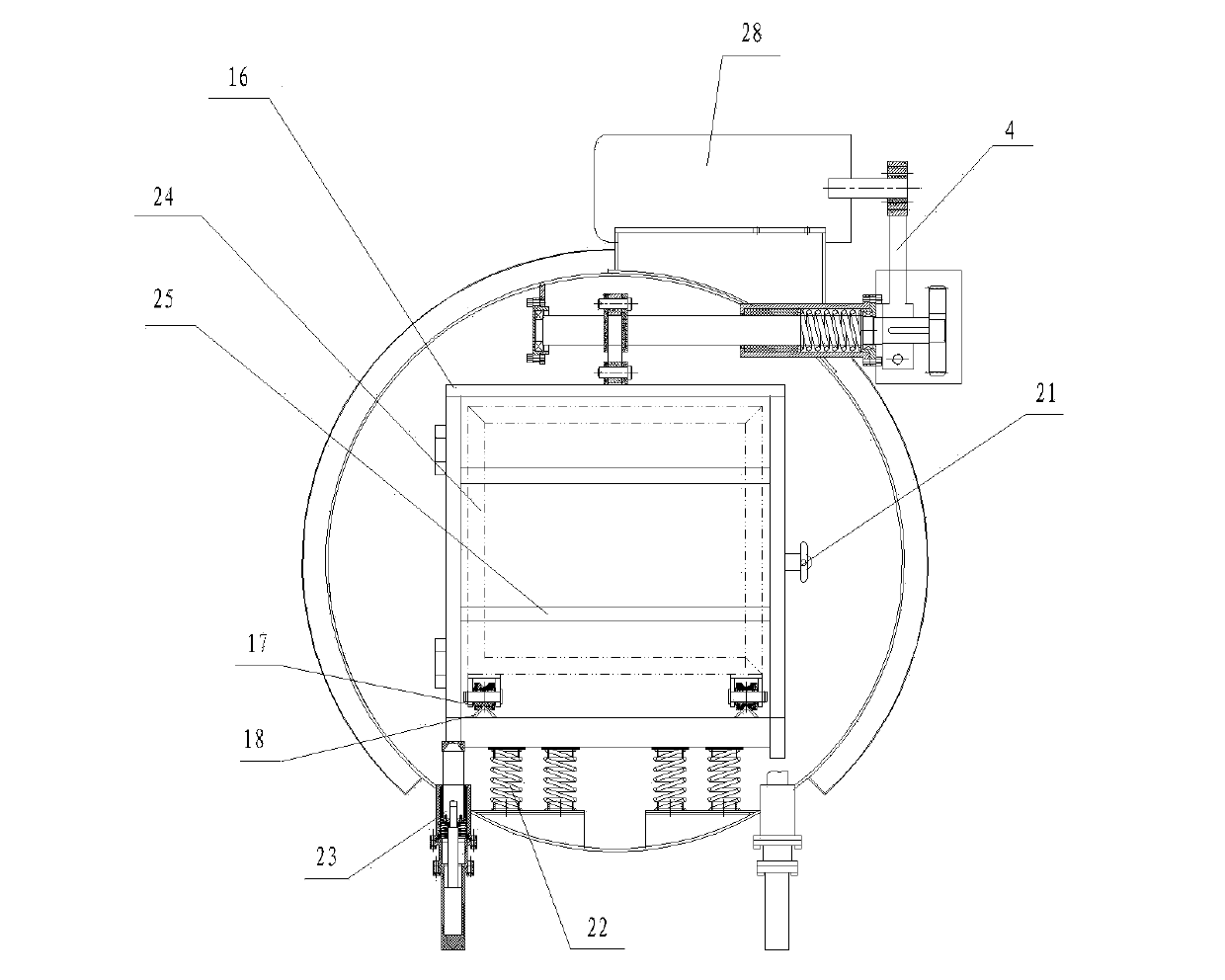

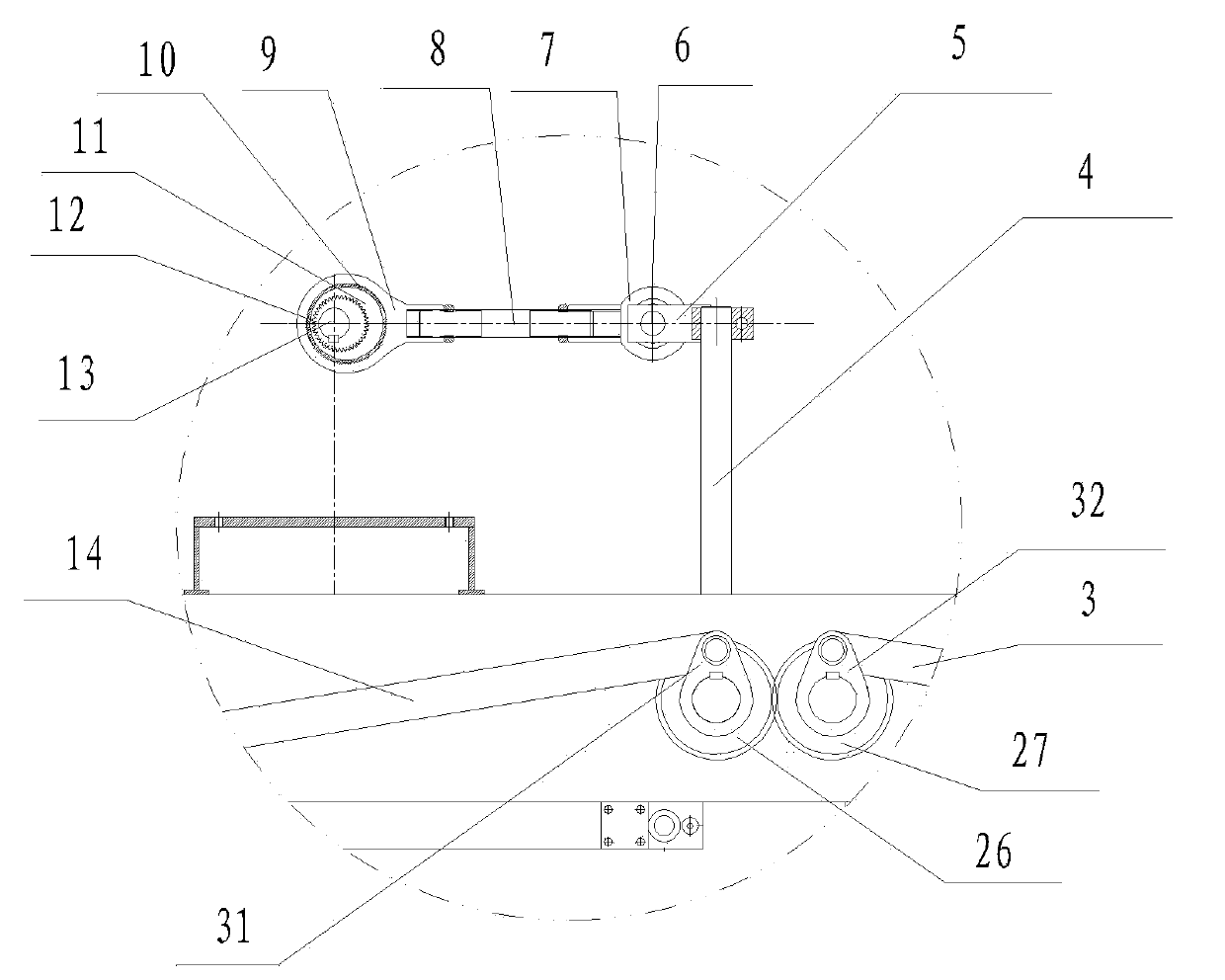

[0041] (1) Pack the sterilized canned pop cans or other packaging container products into the basket 24;

[0042] (2) Place the cage basket 24 in the shaker 16 and fix it;

[0043] (3) Close the cylinder door 1 of the horizontal shaker and inject 3 / 4 of the water into it;

[0044] (4) Start the cycloid reducer and drive motor 28 of the shaking table device, so that the sterilized products are always in an orderly shaking process during the whole sterilization process; the shaking frequency is 80 times / min, and the shaking table swings The amplitude is 30mm.

[0045] (5) Heating the water used in the shaker 16, when the water temperature in the cylinder 20 of the horizontal shaker reaches 85°C, keep it warm for 80 minutes;

[0046] (6) Adjust the pressure in the cylinder 20 of the horizontal shaker to 0.13Mpa during the heating process;

[0047] (7) Cool down to 20°C after the holding time is over;

[0048] (8) When the cooling process is over, discharge the water in the cy...

Embodiment 2

[0052] (1) Pack the sterilized canned pop cans or other packaging container products into the basket 24;

[0053] (2) Place the cage basket 24 in the shaker 16 and fix it;

[0054] (3) Close the cylinder seal door 1 of the horizontal shaker and inject 3 / 4 of water into the cylinder of the horizontal shaker;

[0055] (4) Start the cycloid reducer and drive motor 28 of the shaker device, so that the sterilized product is always in the process of being violently shaken during the whole sterilization process; the shaker vibration frequency is set to 10 times / min, and the shaker swings The amplitude is 10mm.

[0056] (5) Heat the water used in the cylinder 20 of the horizontal shaker, and when the water temperature reaches 70°C, keep it warm for 60 minutes;

[0057] (6) Adjust the pressure in the cylinder 20 of the horizontal shaker to 0.20Mpa during the heating process;

[0058] (7) Cool down to 40°C after the holding time is over;

[0059] (8) When the cooling process is over...

Embodiment 3

[0063] (1) Pack the sterilized canned pop cans or other packaging container products into the basket 24;

[0064] (2) Place the cage basket 28 in the shaker 16 and fix it;

[0065] (3) Close the cylinder door 1 of the horizontal shaker and inject 3 / 4 of the water into the shaker;

[0066] (4) Start the cycloid reducer and drive motor 28 of the horizontal shaker 16 device, so that the sterilized product is always in the process of being violently shaken during the whole sterilization process; the shaker vibration frequency is 200 times / min, The swing range of the shaker is 100mm.

[0067] (5) Heat the water used in the cylinder of the horizontal shaker, when the water temperature reaches 100°C, keep it warm for 100 minutes;

[0068] (6) Adjust the pressure in the cylinder 20 of the horizontal shaker to 0.25Mpa during the heating process;

[0069] (7) Cool down to 60°C after the holding time is over;

[0070] (8) When the cooling process is over, discharge the water in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com