Non-isocyanate polyurethane monomer and preparation method thereof

A polyurethane monomer, non-isocyanate technology, used in the preparation of carboxylic acid amides, the preparation of carbamate derivatives, chemical instruments and methods, etc., can solve the problems of high price, harsh preparation conditions, hinder the development of NIPU, etc. Corrosive, simple synthesis method, simple and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

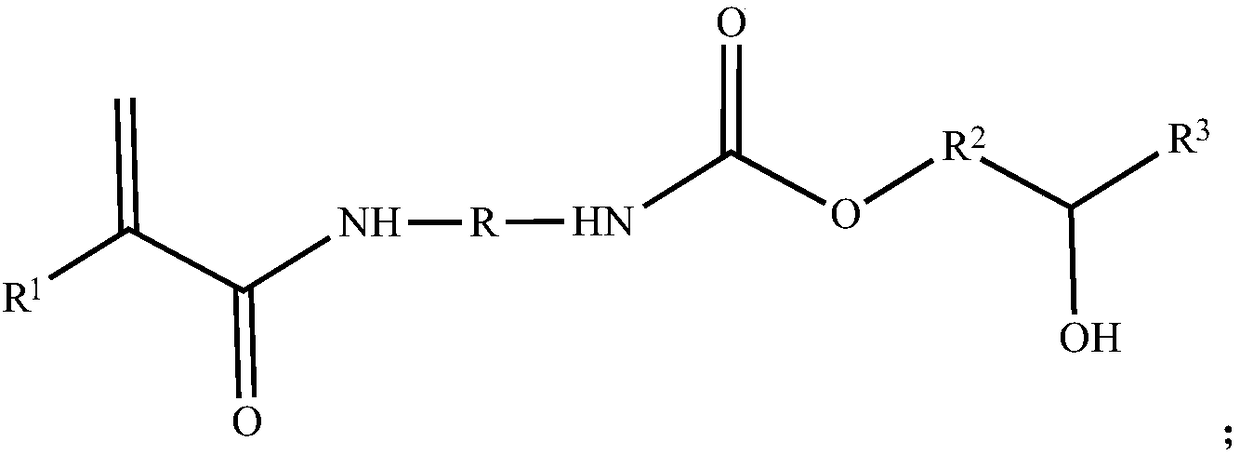

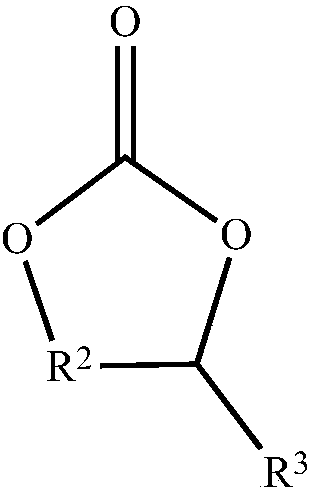

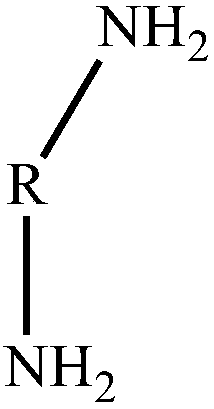

[0052]Prepare described non-isocyanate polyurethane monomer, the first method specifically comprises the following steps:

[0053] S11. Uniformly dissolve propylene carbonate and ethylenediamine in a molar ratio of 1:1 into 50ml of solvent acetonitrile respectively to obtain propylene carbonate solution and ethylenediamine solution. The dripping speed is 1ml / min, drop into the ethylenediamine solution and react for 10 hours to obtain a mixed solution. If the propylene carbonate in the mixed solution is completely reacted by using online infrared or NMR, then use a rotary evaporator to remove the Solvent acetonitrile and remaining ethylenediamine are removed to obtain the first reaction intermediate, and the specific reaction equation is as follows:

[0054]

[0055] S12. Take 0.01 mol of acrylic acid and 0.01 mol of the first reaction intermediate obtained in step S1 and drop them into 50 ml of solvent acetonitrile at the same time at 1 ml / min, react at room temperature for...

Embodiment 2

[0064] Prepare described non-isocyanate polyurethane monomer, the first method specifically comprises the following steps:

[0065] S1. Dissolve propylene carbonate and ethylenediamine in a molar ratio of 1:1.5 into 70ml of solvent acetonitrile respectively to obtain propylene carbonate solution and ethylenediamine solution. The dripping speed is 10ml / min, drip into the ethylenediamine solution and react for 15 hours to obtain a mixed solution. If the propylene carbonate in the mixed solution is completely reacted by using online infrared or nuclear magnetic field, then use a rotary evaporator to remove the Solvent acetonitrile and remaining ethylenediamine are removed to obtain the first reaction intermediate, and the specific reaction equation is as follows:

[0066]

[0067] S2. Take 0.02mol of acrylic acid and 0.02mol of the first reaction intermediate obtained in step S1 and drop them into 70ml of solvent acetonitrile at the same time at 6ml / min, react at room temperat...

Embodiment 3

[0076] Prepare described non-isocyanate polyurethane monomer, the first method specifically comprises the following steps:

[0077] S1. Dissolve propylene carbonate and ethylenediamine uniformly in 60ml of solvent acetonitrile respectively according to the molar ratio of 1:1.25 to obtain propylene carbonate solution and ethylenediamine solution. The dripping speed is 5ml / min and drips into the ethylenediamine solution and reacts for 12 hours to obtain a mixed solution. If the propylene carbonate in the mixed solution is completely reacted using online infrared or NMR, then use a rotary evaporator to remove the Solvent acetonitrile and remaining ethylenediamine are removed to obtain the first reaction intermediate, and the specific reaction equation is as follows:

[0078]

[0079] S2. Take 0.01mol of acrylic acid and 0.01mol of the first reaction intermediate obtained in step S1 and drop them into 60ml of solvent acetonitrile at the same time at 3ml / min, react at room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com