Vacuum cleaner having a blower capsule

A technology for vacuum cleaners and fans, which is applied in the installation of vacuum cleaners, motor fan components, household appliances, etc. It can solve the problems of the smooth wall of the flow channel, etc., and achieve the effect of reducing the types of parts and sealing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

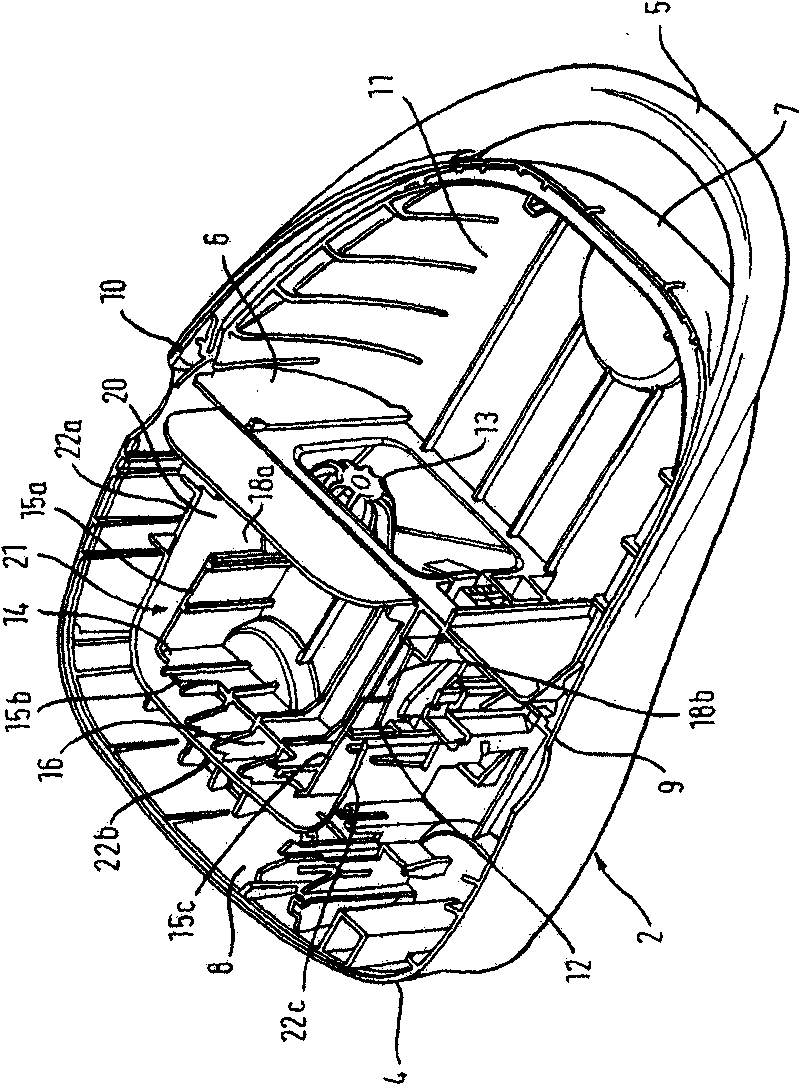

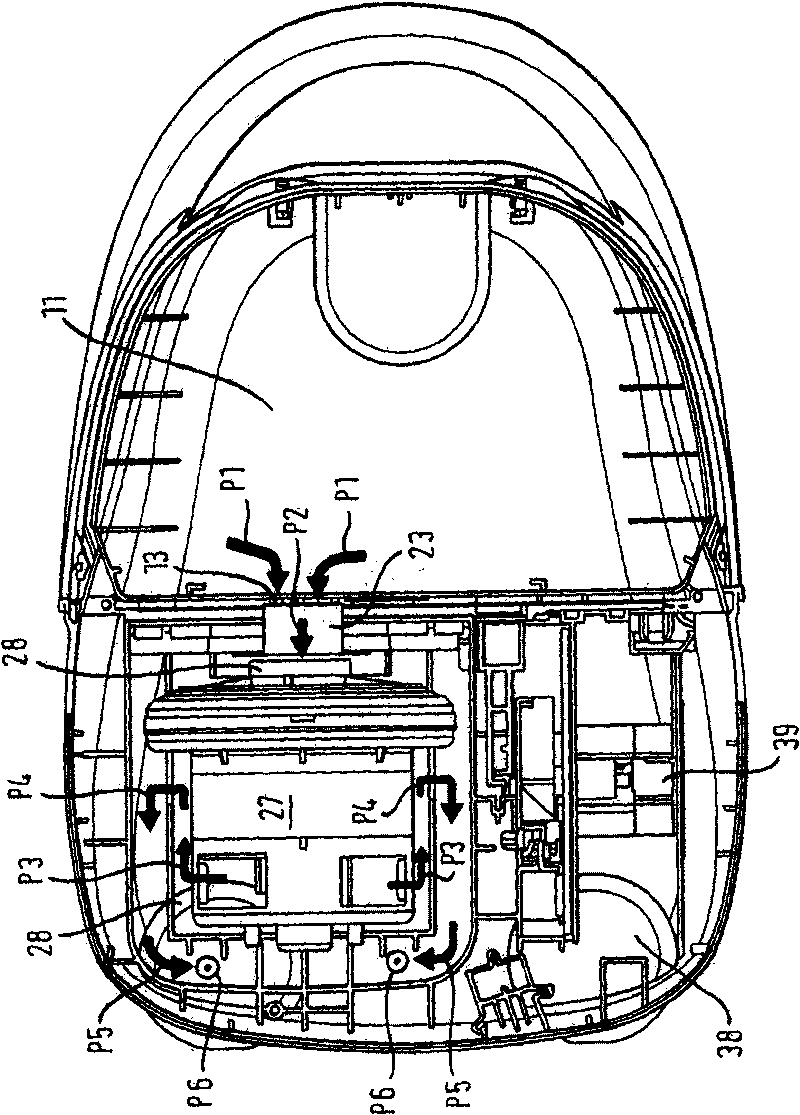

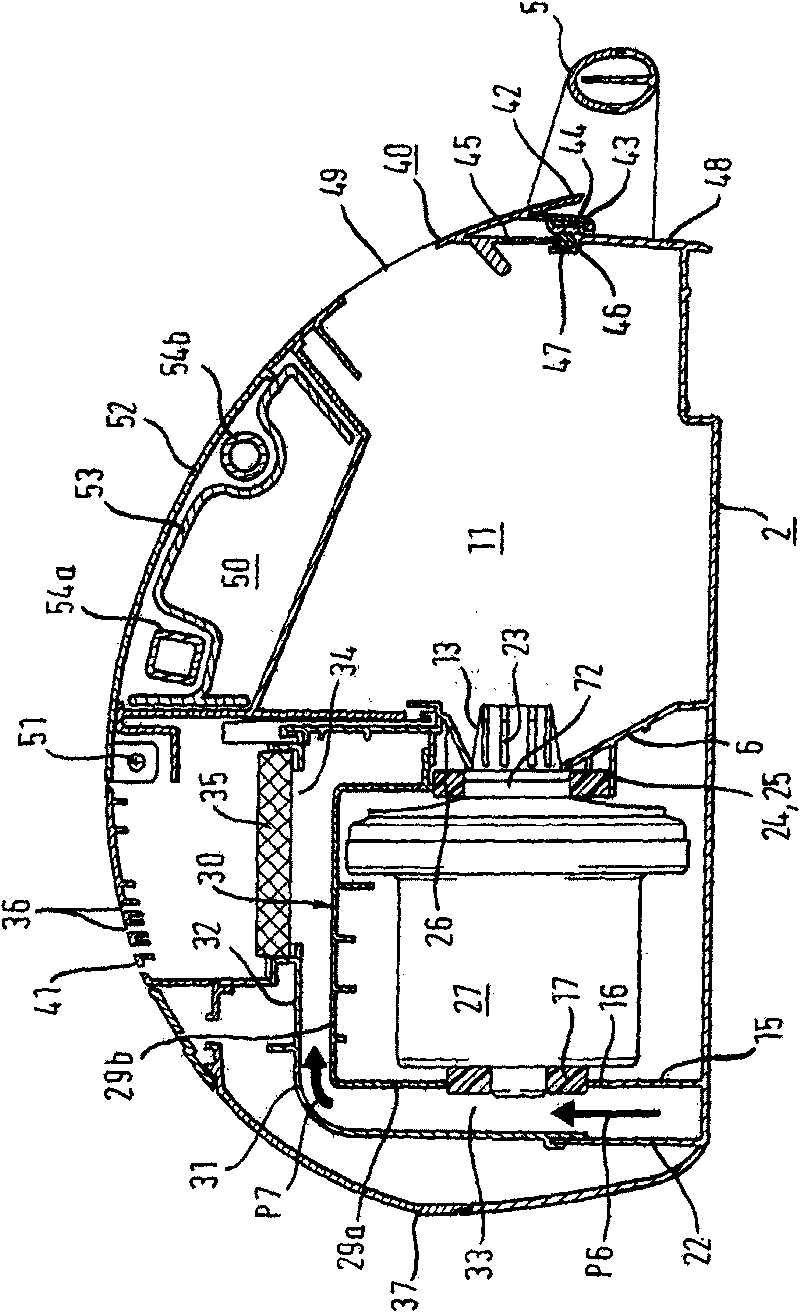

[0026] An embodiment of a vacuum cleaner according to the invention has a housing 1 with a bottom housing 2 in the figure 1 shown in . The base housing 2 is designed in the form of a wall and has a base 3 and a surrounding housing wall 4 . The housing wall 4 extends substantially vertically upwards starting from an edge region of the base 3 . At a front end of the base housing 1 , on the outer side of the housing wall 4 , a handle 5 is integrally formed on the base housing 2 . A partition wall 6 is arranged in the interior of the base housing 2 approximately midway between the front end 7 of the base housing 2 and a rear end 8 of the base housing 2 . Partition wall 6 from figure 1 A first side wall section 9 , shown at the front center left, extends as far as a second side wall section 10 , shown at the rear right of the housing wall 4 . The partition wall 6 divides the bottom housing 2 into a front dust collection chamber 11 and a rear fan chamber 12 . The partition wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com