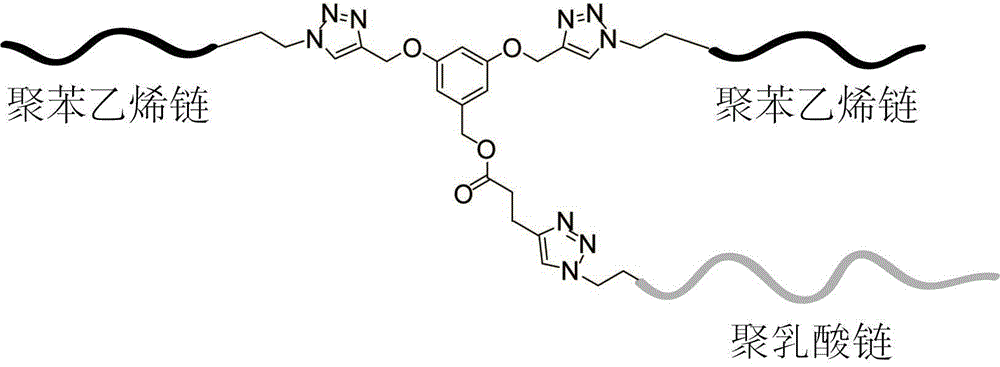

A kind of radial block copolymer and preparation method thereof

A technology of block copolymer and polylactic acid, which is applied in the field of star block copolymer and its preparation, can solve the problems of difficult preparation, low coupling efficiency, side reactions, etc., and achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

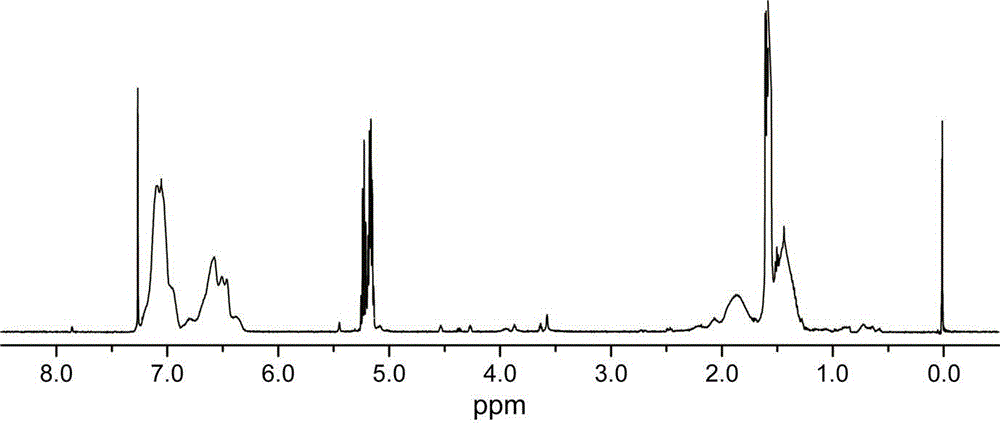

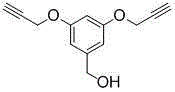

[0021] Weigh 8.0 g of polystyrene containing an azide end group with a molecular weight of 10000, 86.5 mg of compound A, 0.45 g of sodium ascorbate, and 1.05 g of copper sulfate, dissolve them in a mixed solvent composed of tetrahydrofuran / water, and react at room temperature for 24 hours. Evaporate the organic solvent under reduced pressure, precipitate with methanol, filter and dry in vacuo to obtain a two-arm polystyrene with a hydroxyl group in the center; dissolve the two-arm polystyrene with a hydroxyl group in the center in dichloromethane , add 0.5g 4-dimethylaminopyridine and 0.3g 4-pentynoic acid, and react at room temperature for 10 hours. Dichloromethane was distilled off under reduced pressure, precipitated with methanol, filtered and vacuum-dried to obtain a two-arm polystyrene with an alkynyl group in the central point; taking the two-arm polystyrene with an alkynyl group in the central point, the molecular weight was 15000 polylactic acid containing an azide te...

Embodiment 2

[0023] Weigh 6.0 g of polystyrene with a molecular weight of 20,000 containing an azide end group, 32.4 mg of compound A, 0.23 g of sodium ascorbate, and 0.53 g of copper sulfate, dissolve them in a mixed solvent of tetrahydrofuran / water, and react at room temperature for 36 hours. Evaporate the organic solvent under reduced pressure, precipitate with methanol, filter and dry in vacuo to obtain a two-arm polystyrene with a hydroxyl group in the center; dissolve the two-arm polystyrene with a hydroxyl group in the center in dichloromethane , add 0.32g 4-dimethylaminopyridine and 0.21g 4-pentynoic acid, and react at room temperature for 24 hours. Dichloromethane was distilled off under reduced pressure, precipitated with methanol, filtered and vacuum-dried to obtain a two-arm polystyrene with an alkynyl group in the central point; taking the two-arm polystyrene with an alkynyl group in the central point, the molecular weight was 23000 polylactic acid containing an azide terminal...

Embodiment 3

[0025] Weigh 10.0g of polystyrene with a molecular weight of 15,000 containing an azide terminal group, 72.0mg of compound A, 0.43g of sodium ascorbate, and 0.98g of copper sulfate, dissolve them in a mixed solvent composed of tetrahydrofuran / water, and react at 40°C for 20 hours, evaporate the organic solvent under reduced pressure, precipitate with methanol, filter and dry in vacuo to obtain a two-arm polystyrene with a hydroxyl group in the center; dissolve the two-arm polystyrene with a hydroxyl group in the center in dichloro Add 0.75g of 4-dimethylaminopyridine and 0.68g of 4-pentynoic acid to methane, and react at room temperature for 36 hours. Dichloromethane was distilled off under reduced pressure, precipitated with methanol, filtered and vacuum-dried to obtain a two-arm polystyrene with an alkynyl group in the central point; taking the two-arm polystyrene with an alkynyl group in the central point, the molecular weight was 12000 polyethylene oxide containing an azid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com