Degradable poly (butylene adipate-co-terephthalate) composite high-oxygen-barrier film as well as preparation method and application thereof

A technology of butylene terephthalate and polyadipic acid, which is applied in the direction of sustainable manufacturing/processing, sustainable packaging industry, climate sustainability, etc., can solve the problem of poor dispersion and low barrier property of the blend system , environmental pollution and other issues, achieve the effect of smooth and uniform membrane surface, no structural defects, and reduce white pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

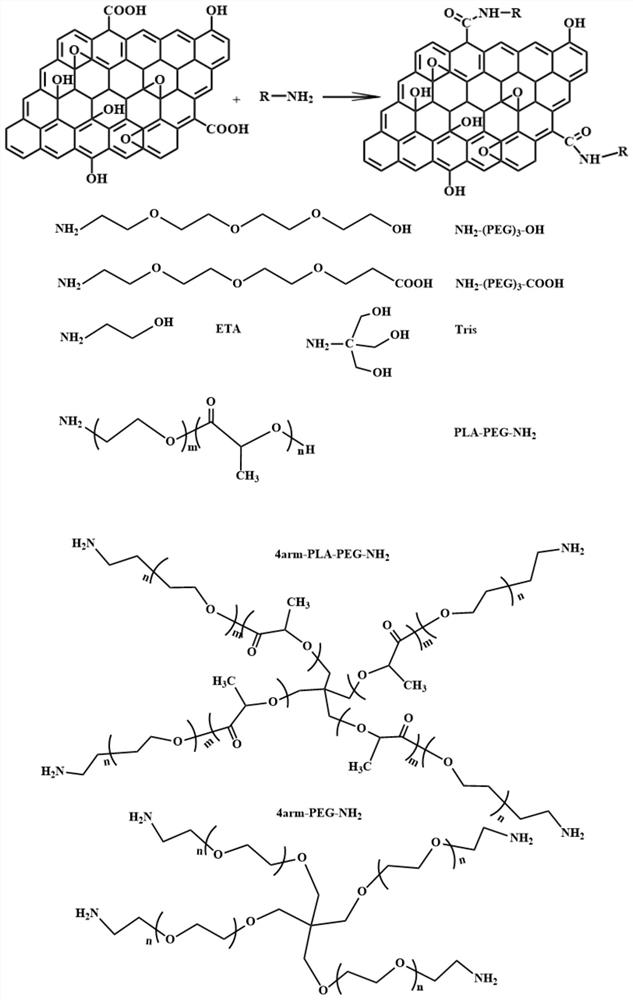

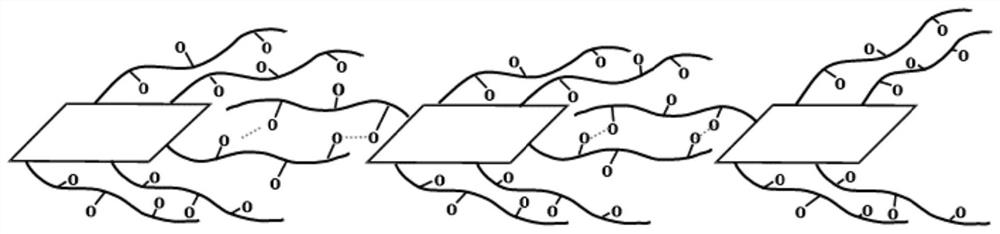

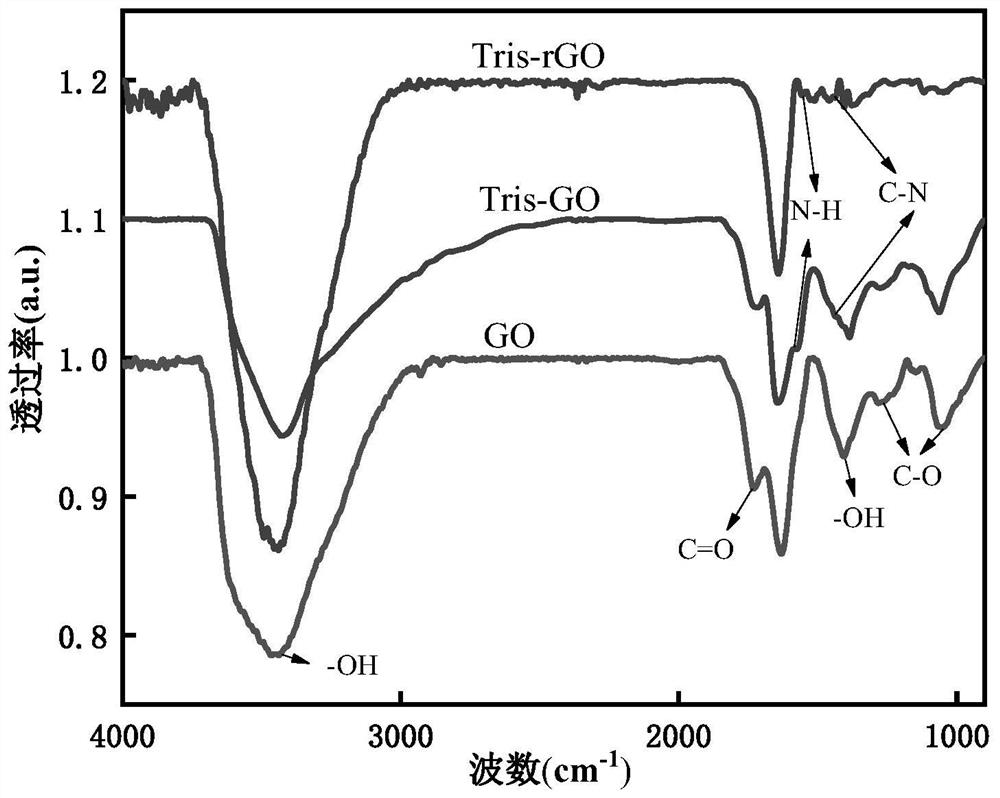

[0039] 40 mg of graphene oxide (GO) was added to 40 mL of deionized water, and sonicated for 1 h until GO was completely dispersed; EDC and NHS (40 mg each) were added to activate the edge carboxyl groups, and the reaction was stirred at room temperature (300 rpm) for 30 min; 3.2 mmol was added. Tris(hydroxymethylaminomethane) modifier, adjust the pH to 4.5 with buffer; continue to stir at room temperature (rotation speed is 300rpm) and react for 18h; wash the reacted product with DMF and deionized water respectively, and centrifuge (rotation speed: 10000rpm) After 20 min, it was dried in a drying oven (50 °C) for 8 h to obtain the edge-modified graphene oxide (f-GO1). image 3 As can be seen in the IR spectrum shown, Tris-GO modified graphene oxide (Tris-GO) at 1570 cm compared to pristine GO. -1 The N-H in-plane vibration peak in the amide bond appears at 1427cm -1 The C-N bond stretching vibration peak appeared at the position, indicating that the polar molecular chain con...

Embodiment 2

[0042] With reference to the modification method of graphene oxide in Example 1, use amino-polyethylene glycol-hydroxyl to replace trimethylolaminomethane, and the amount of carboxyl activator EDC and NHS is increased to 60mg, amino-polyethylene glycol The amount of alcohol-hydroxyl groups was changed from 3.2 mmol to 2.8 mmol, and the other parameters and reaction conditions remained unchanged, and amino-polyethylene glycol-hydroxyl edge-modified graphene oxide (f-GO2) and modified graphene (f-GO2) were prepared. f-rGO2).

Embodiment 3

[0044] Referring to the modification method of graphene oxide in Example 1, replace tris(hydroxymethyl)aminomethane with polylactic acid-polyethylene glycol-amino group of the same mole number, and change the pH from 4.5 to 6, and change the reaction time from 18h to After 20 h, other parameters and reaction conditions were kept unchanged, and polylactic acid-polyethylene glycol-amino edge-modified graphene oxide (f-GO3) and edge-modified graphene (f-rGO3) were prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com