A processing method for producing isostatic cylindrical graphite using an isostatic graphite cylindrical material forming die

A technology of isostatic pressing forming and processing method, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of difficult mass production, difficult process, etc., to reduce cost loss, process difficulty and quality. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

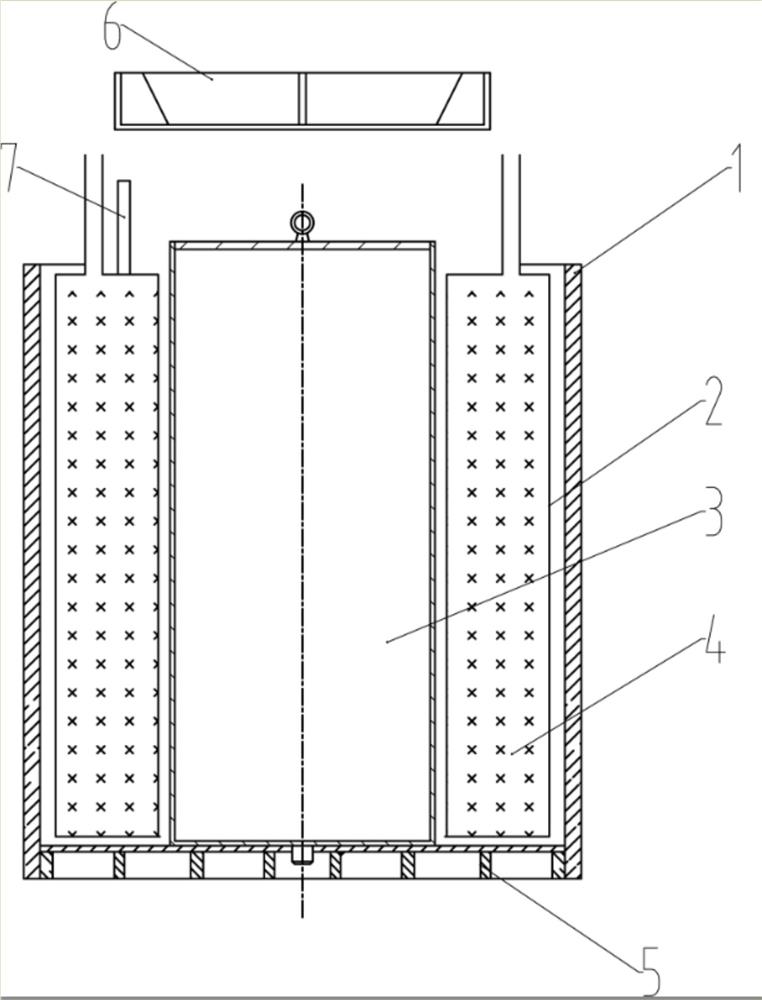

[0050] A kind of isostatic graphite cylinder material molding die provided by the preferred embodiment of the present invention comprises a mold steel barrel 1, a plastic bag 2, an inner core barrel 3, a base 5, a support ring 6 and a vacuum tube 7, and the inner core barrel 3 is smaller than the diameter of the mold steel barrel 1 and the plastic bag 2, the plastic bag 2 and the inner core barrel 3 are installed on the base 5, and the base 5 is set on the bottom of the lower end of the mold steel barrel 1, and the plastic bag 2 Laid in the gap between the inner core barrel 3 and the mold steel barrel 1, the vacuum tube 7 communicates with the inside of the plastic bag 2, and the support ring 6 is sealed and installed at the inner opening of the plastic bag 2 for vacuuming .

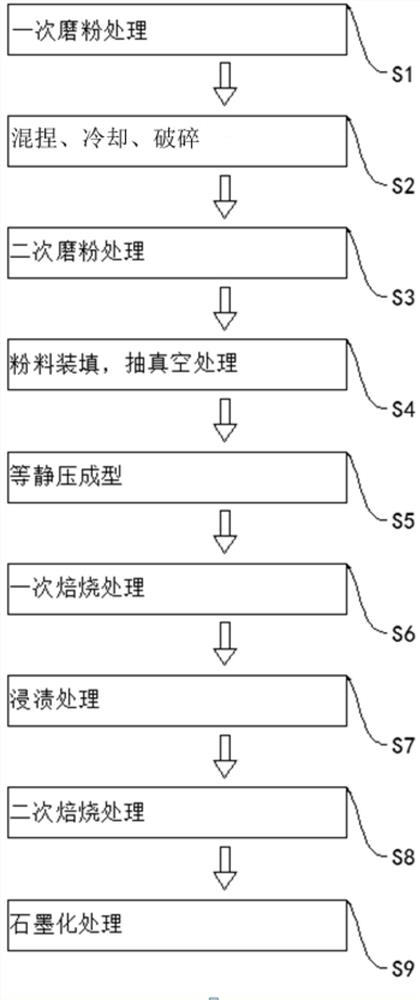

[0051] A processing method for producing isostatic cylindrical graphite, comprising the steps of,

[0052] Choose pitch coke as raw material, and carry out a grinding treatment;

[0053] Use modified asp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com