Preparation method of anti-corrosion film

A corrosion-resistant film and film technology, which is applied to the surface coating liquid device, special surface, pre-treated surface, etc., can solve the problems of aging degradation, loss of silver protection, etc., to achieve good corrosion resistance and prolong corrosion resistance time, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

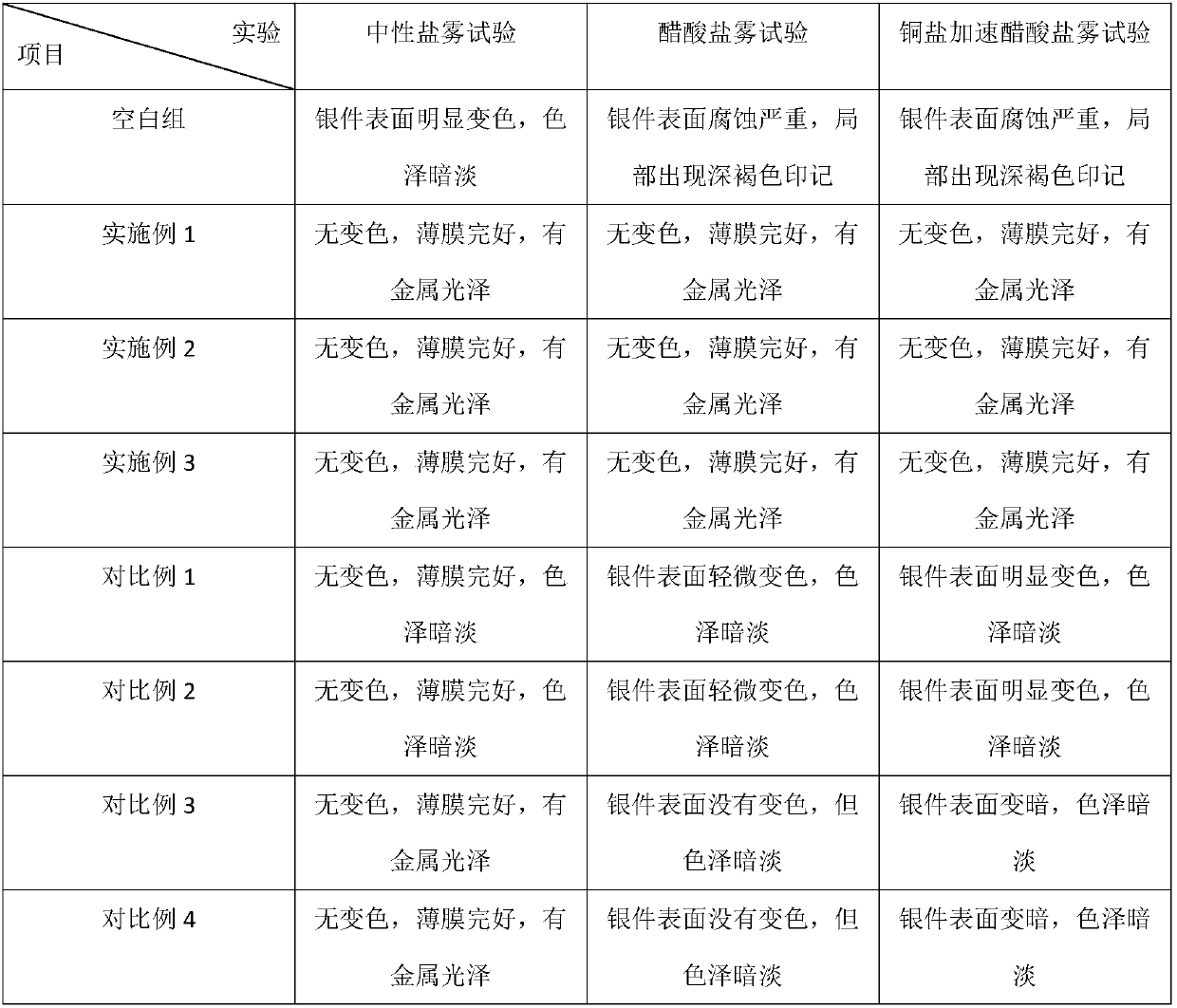

Examples

Embodiment 1

[0040] (1) Add 121.36g tetraethyl orthosilicate, 486g dehydrated ethanol and 1214g deionized water in order, after mixing uniformly, stir at room temperature for 60 minutes to carry out hydrolysis to obtain an organic solution of tetraethyl orthosilicate;

[0041] (2) 17.76g of boric acid was added to the organic solution of ethyl orthosilicate, and stirred at room temperature for 20 minutes to obtain a transparent solution A;

[0042] (3) Slowly add 775g of bismuth nitrate solution with a mass concentration of 10% in solution A, stir and mix for 120 minutes at room temperature to obtain a transparent intermediate;

[0043] (4) Take out after immersing the silver piece in the intermediate for 30 seconds, place the silver piece in a ventilated place for 24 hours, and form an intermediate layer on the surface of the silver piece;

[0044] (5) Carrying out heat treatment to the intermediate layer, the heat treatment includes heating the temperature from room temperature to 250°C ...

Embodiment 2

[0046] (1) Add 121.5g tetraethyl orthosilicate, 486g absolute ethanol and 1215g deionized water in sequence, after uniform mixing, stir at room temperature for 50 minutes for hydrolysis to obtain an organic tetraethyl orthosilicate solution;

[0047] (2) 26.6g of boric acid was added to the organic solution of ethyl orthosilicate, and stirred at room temperature for 15 minutes to obtain a transparent solution A;

[0048] (3) Slowly add 775g of bismuth nitrate solution with a mass concentration of 10% in solution A, stir and mix for 100 minutes at room temperature to obtain a transparent intermediate;

[0049] (4) Take out after soaking the silver piece in the intermediate for 20 seconds, put the silver piece in a ventilated place for 22 hours, and form an intermediate layer on the surface of the silver piece;

[0050] (5) Carrying out heat treatment to the intermediate layer, the heat treatment includes heating the temperature from room temperature to 300°C at a rate of 3°C / mi...

Embodiment 3

[0052] (1) Add 121.36g tetraethyl orthosilicate, 486g dehydrated ethanol and 1214g deionized water in order, after uniform mixing, stir at room temperature for 70 minutes for hydrolysis to obtain an organic solution of tetraethyl orthosilicate;

[0053] (2) 17.76g of boric acid was added to the organic solution of ethyl orthosilicate, and stirred at room temperature for 25 minutes to obtain a transparent solution A;

[0054] (3) Slowly add 852 g of bismuth nitrate solution with a mass concentration of 10% in solution A, stir and mix for 140 minutes at room temperature to obtain a transparent intermediate;

[0055] (4) Take out after soaking the silver piece in the intermediate for 40 seconds, place the silver piece in a ventilated place for 26 hours, and the intermediate layer is formed on the surface of the silver piece;

[0056] (5) Carrying out heat treatment to the intermediate layer, the heat treatment includes heating the temperature from room temperature to 250°C at a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com