Modified Mxene/PVA flame-retardant composite material and preparation method thereof

A flame retardant composite material and modification technology, applied in the field of composite materials, can solve problems affecting people's health, mechanical properties and other performance effects, and normal operation of electronic equipment, etc., to achieve a wide range of applications, excellent flame retardant performance, good Effects of Conductive Properties and Electromagnetic Shielding Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

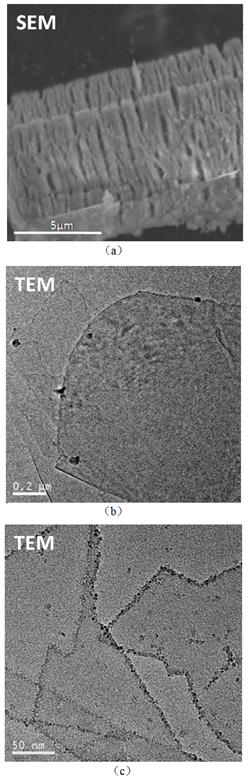

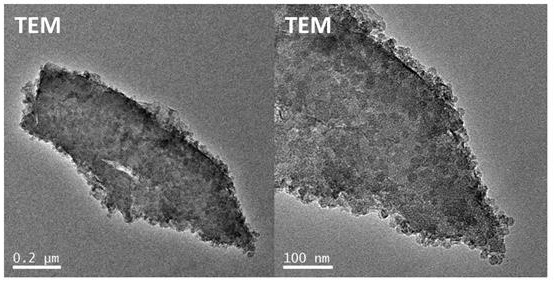

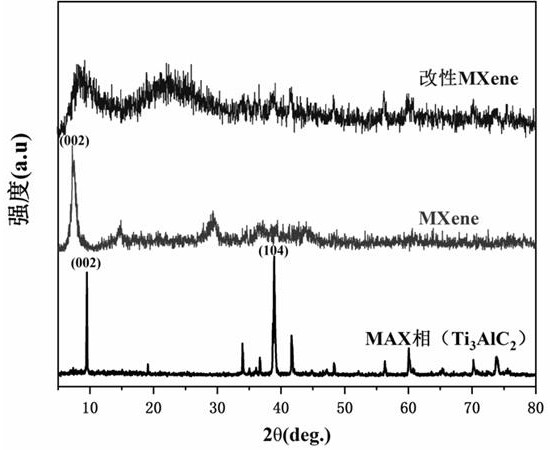

[0033] Add 30mL of hydrochloric acid and 10mL of deionized water into a polytetrafluoroethylene beaker, then add 3.5g of lithium fluoride, stir well at 300r / min for 25min; slowly add 3.5g of titanium aluminum carbide (MAX phase), and then Stir at 400r / min at a constant temperature and react at a constant temperature for 48h at a temperature of °C to obtain a post-reaction solution, wash the post-reaction solution with deionized water until the pH value of the post-reaction solution is neutral, centrifuge at a speed of 3500r / min for 30min, and take The supernatant was used to obtain MXene. Disperse Mxene in deionized water and ultrasonically treat it for 30 minutes to obtain a Mxene dispersion with a mass volume concentration of 2 mg / mL; add 1 g of CTAB to 100 mL of MXene dispersion, and react with magnetic stirring at a speed of 300 r / min for 20 minutes to obtain Mixed solution; use sodium hydroxide to adjust the pH value of the mixed solution to 9.0, and magnetically stir the...

Embodiment 2

[0036] Add 30mL of hydrochloric acid and 10mL of deionized water into a polytetrafluoroethylene beaker, then add 4.5g of lithium fluoride, stir well at 400r / min for 30min, slowly add 4.5g of titanium aluminum carbide (MAX phase), at 55℃ Stir at 600r / min at a constant temperature and react at a constant temperature for 24 hours to obtain a reacted liquid, wash the reacted liquid with deionized water until the pH of the reacted liquid is neutral, centrifuge at a speed of 5000r / min for 10min, and take the Serum, get MXene. Disperse Mxene in deionized water and ultrasonically treat it for 20 minutes to obtain a Mxene dispersion with a mass volume concentration of 2 mg / mL; add 1 g of CTAB to 100 ml of MXene dispersion, and react with magnetic stirring at 200 r / min for 10 minutes to obtain a mixed solution; use sodium hydroxide to adjust the pH of the mixed solution to 9.5, and react with magnetic stirring at 40°C and 200r / min for 8 hours; slowly add 2ml of tetraethyl orthosilicate,...

Embodiment 3

[0038] Add 30mL of hydrochloric acid and 10mL of deionized water into a polytetrafluoroethylene beaker, then add 4.0g of lithium fluoride, stir well at 350r / min for 27min, then slowly add 4.0g of titanium aluminum carbide (MAX phase), at 50℃ Stir and react at a constant temperature at 500r / min under high temperature for 36h to obtain the reacted liquid, wash the reacted liquid with deionized water until the pH value of the reacted liquid is neutral, centrifuge at a speed of 4250r / min for 20min, and take the above Serum, get MXene. Disperse Mxene in deionized water and sonicate for 25 minutes to obtain a Mxene dispersion with a mass volume concentration of 2 mg / ml; add 1 g of CTAB to 100 mL of MXene dispersion solution, and magnetically stir at 250 r / min for 15 minutes to obtain a mixed solution; use sodium hydroxide to adjust the pH value of the mixed solution to 9.25, and react with magnetic stirring at 40°C and 250r / min for 8h; slowly add 2ml of tetraethyl orthosilicate, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com