Halogen-free flame-retardant master batch and preparation method thereof, and glass fiber reinforced nylon material and preparation method thereof

A technology of flame retardant masterbatch and glass fiber, which is applied in the field of preparation of halogen-free flame retardant masterbatch for glass fiber reinforced nylon, can solve the problems of migration and corrosion of equipment of halogen-free flame retardant masterbatch, and achieves stable color and dispersibility. Improve and enhance the effect of dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

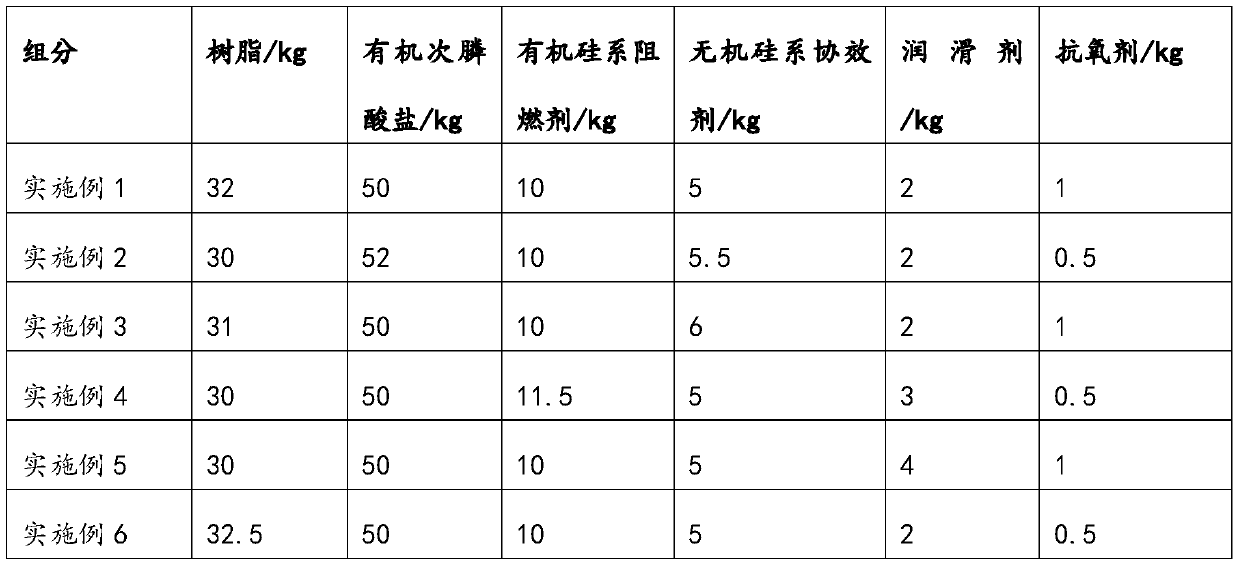

[0065] This example shows a halogen-free flame-retardant masterbatch and its preparation process. The components of the halogen-free flame-retardant masterbatch are shown in Table 1.

[0066] Its preparation process includes the following steps:

[0067] Step 1): Mix the resin (PA6) and antioxidant (phenolic antioxidant 1098) evenly and feed them into the extruder through an active feeding device.

[0068] Step 2): Then organic phosphinate (diethyl aluminum phosphinate, average particle size D50 is 30 μm), organosilicon flame retardant (silicone rubber), inorganic silicon synergist (nano silicon dioxide ) and lubricant (silicone powder and lithium stearate 1:1 combination) are evenly mixed, and are fed into the extruder through the side feeding device of the extruder.

[0069] Step 3): Melt blending and extruding the mixture in step 1). The temperature of each zone of the extruder is controlled between 180°C and 200°C. Specifically, the temperature zone of the extruder is 12...

Embodiment 1B

[0071] This embodiment shows a kind of preparation technology that adopts the method for embodiment 1A to prepare glass fiber reinforced nylon material, comprises the following steps:

[0072] Step 1): Take the method of Example 1A to prepare 2.5kg of halogen-free flame-retardant masterbatch, 4.5kg of nylon 66, 3.0kg of glass fiber and 0.5kg of auxiliary agent and mix evenly;

[0073] Step 2): Use a twin-screw extruder with a diameter of Φ36 and a length-to-diameter ratio of 40 to complete extrusion and granulation. The granulated material is sieved and dried to obtain a glass fiber-reinforced nylon material. The performance of the glass fiber-reinforced nylon material is Please refer to Table 2.

Embodiment 2A

[0075] This example shows a halogen-free flame-retardant masterbatch and its preparation process. The components of the halogen-free flame-retardant masterbatch are shown in Table 1.

[0076] Its preparation process includes the following steps:

[0077] This example shows a halogen-free flame-retardant masterbatch and its preparation process. The components of the halogen-free flame-retardant masterbatch are shown in Table 1.

[0078] Its preparation process includes the following steps:

[0079] Step 1): Mix the resin (PA12) and antioxidant (thioether antioxidant DLTP) evenly and feed them into the extruder through an active feeding device.

[0080] Step 2): then organic silicon phosphinate (aluminum phenyl phosphinate, average particle diameter D50 is 20 μm), organosilicon flame retardant (cage silsesquioxane), inorganic silicon synergist ( Low melting point glass powder) and lubricant (aluminum stearate) are mixed evenly, and are fed into the extruder through the side fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com