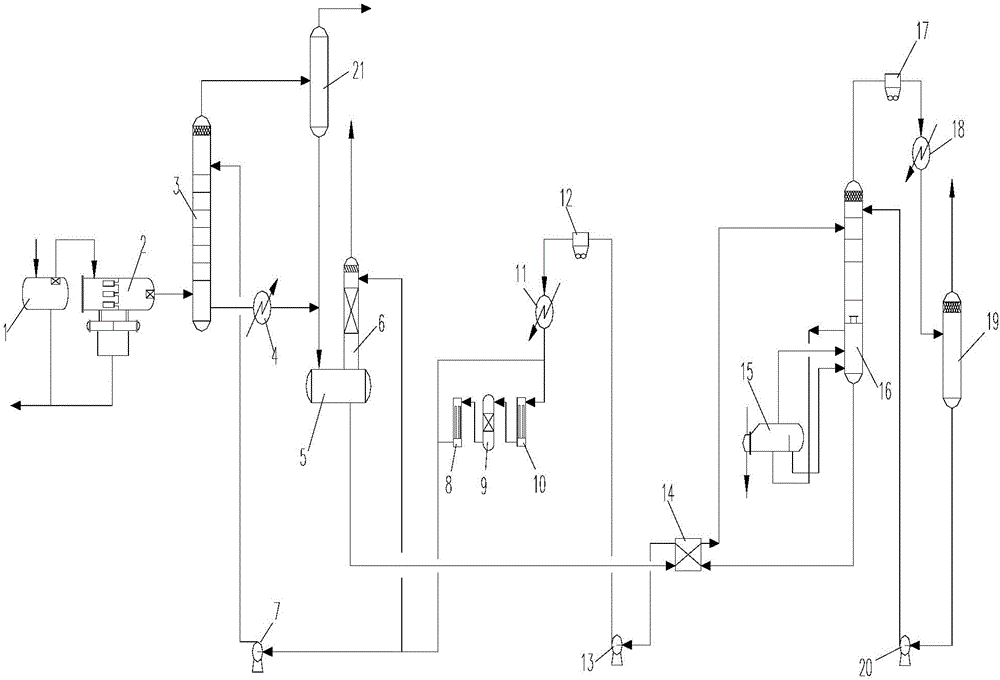

High-efficiency composite desulphurization solvent and system and method for removing acidic gas and organic sulfur

A technology for acid gas and organic sulfur, which is used in the field of removing hydrogen sulfide, organic mercaptan remover, and carbon dioxide. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1. The new high-efficiency composite desulfurization solvent of the present invention is composed of the following raw materials according to mass percentage: 50% of N-methyldiethanolamine, 22.39% of N-methyl-benzylethanolamine, 3-aza-2,2-dimethyl Hexylene glycol 10%, sulfolane 10%, N-hydroxyethylmorpholine 6%, defoamer 0.01%, benzylamine antioxidant 0.6%, heterocyclic amine preservative 1%, this composite desulfurization solvent is formulated with water 45% solution, used for feed gas composition: low carbon hydrocarbon 89.5%, H 2 S4.2%, CO 2 6.26%, the gas purification of methyl mercaptan 216PPm, ethanethiol 142PPm, and isopropyl mercaptan 37PPm, the H in the purified gas 2 S is 10PPm, CO 2 2.2%, mercaptan 103PPm, mercaptan removal rate 74%, the acid gas load of solvent 0.66mol (H 2 S+CO 2 ) / mol amine.

Embodiment 2

[0037] Example 2, the new high-efficiency composite desulfurization solvent of the present invention is composed of the following raw materials according to mass percentage: 45% of N-methyldiethanolamine, 22% of N-methyl-benzylethanolamine, 3-aza-2,2-dimethyl Hexylene glycol 10.39%, sulfolane 15%, N-hydroxyethylmorpholine 6%, defoamer 0.01%, benzylamine antioxidant 0.5%, heterocyclic amine preservative 1.1%, this composite desulfurization solvent is formulated with water 45% solution, used for raw material gas composition: 90.1% of low carbon hydrocarbons, H 2 S4.4%, CO 2 5.45%, the gas purification of methyl mercaptan 256PPm, ethanethiol 180PPm, and isopropyl mercaptan 49PPm, the H in the purified gas 2 S is 9PPm, CO 2 2.2%, mercaptan 98PPm, mercaptan removal rate 79.8%, the acid gas load of solvent 0.68mol (H 2 S+CO 2 ) / mol amine.

Embodiment 3

[0038] Example 3, the new high-efficiency composite desulfurization solvent of the present invention is composed of the following raw materials according to mass percentage: 43% of N-methyldiethanolamine, 15% of N-methyl-benzylethanolamine, 3-aza-2,2-dimethyl Hexylene glycol 10.39%, sulfolane 20%, N-hydroxyethylmorpholine 10%, defoamer 0.01%, benzylamine antioxidant 0.5%, heterocyclic amine preservative 1.1%, this composite desulfurization solvent is formulated with water 45% solution, used for feed gas composition: low carbon hydrocarbon 89.5%, H 2 S4.2%, CO 2 6.26%, the gas purification of 256PPm of methyl mercaptan, 182PPm of ethanethiol, and 47PPm of isopropyl mercaptan, the H in the purified gas 2 S is 10PPm, CO 2 2.4%, mercaptan 84PPm, mercaptan removal rate 82.6%, the acid gas load of solvent 0.68mol (H 2 S+CO 2 ) / mol amine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com