Efficient solvent for removing thioether and thiophene and application thereof

A thiophene and solvent technology, applied in the field of high-efficiency desulfurization ether and thiophene solvent, can solve the problem that the desulfurization solvent cannot meet the requirements, etc., and achieve the effects of low regeneration energy consumption, high economic benefit, and good removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

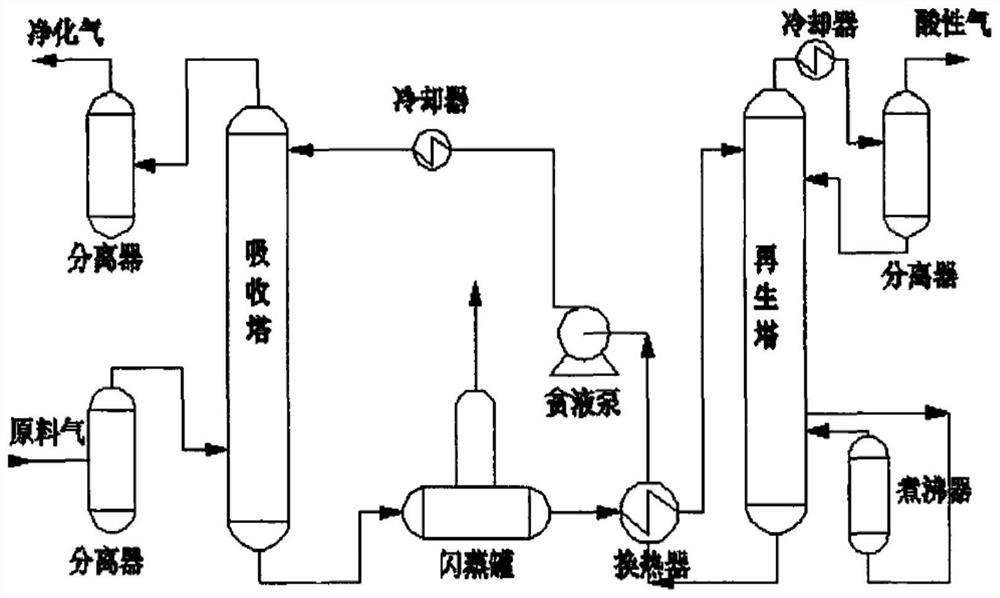

Method used

Image

Examples

Embodiment 1

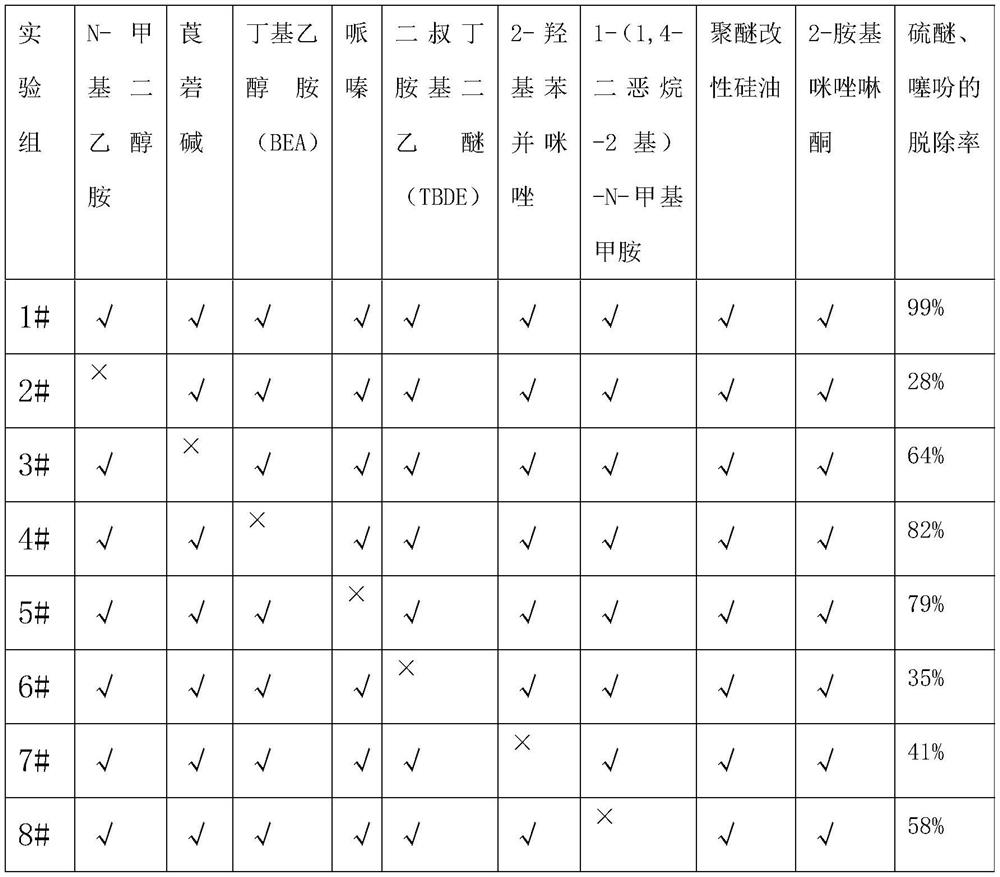

[0052] A high-efficiency desulfurization ether and thiophene solvent, including the following components in mass percentage: N-methyldiethanolamine 14%, butylethanolamine (BEA) 5%, piperazine 3%, di-tert-butylaminodiethyl ether (TBDE) 20.38 %, hyoscyamine 7%, 2-hydroxybenzimidazole 35%, 1-(1,4-dioxan-2 base)-N-methylmethylamine 15%, polyether modified silicone oil 0.02%, 2- Aminoimidazolinone 0.6%.

[0053] According to the above proportion relationship, the various components are mixed evenly, and the high-efficiency desulfurization ether and thiophene solvent prepared by the preparation are prepared into a 45wt% solution with water, and filled into an absorption tower of a high-efficiency removal of sulfide and thiophene system. Remove sulfide, thiophene, etc. from the gas.

[0054] The absorption tower is equipped with high-efficiency desulfurization ether and thiophene solvents. The absorbent-rich liquid obtained after absorption is flashed through the flash tower, and th...

Embodiment 2

[0056] A high-efficiency desulfurization ether and thiophene solvent, including the following components in mass percentage: 14% of N-methyldiethanolamine, 7% of diethanolamine (DEA), 2% of piperazine, and 15% of di-tert-butylaminodiethyl ether (TBDE) , hyoscyamine 7.88%, 2-(2-methoxyanilino)-methyl-1,3 tetrahydrothiazole 33%, 6-amino-1,4-benzodioxane 21%, polyether modified 0.03% silicone oil, 0.9% boric acid corrosion inhibitor. The high-efficiency desulfurization ether and thiophene solvent prepared above in proportion is prepared into a 50wt% solution with water, and loaded into an absorption tower of a high-efficiency desulfurization ether and thiophene system for removal of sulfide and thiophene from raw material gas.

[0057] The absorbent-rich liquid obtained after absorption is flashed through the flash tower, and the obtained semi-lean liquid enters the lean-rich liquid heat exchanger for heat exchange and then enters the regeneration tower for regeneration. The rege...

Embodiment 3

[0059] A high-efficiency desulfurization ether and thiophene solvent, including the following components in mass percentage: N-methyldiethanolamine 23%, butylethanolamine (BEA) 2%, piperazine 1.5%, di-tert-butylaminodiethyl ether (TBDE) 5.34 %, hyoscyamine 12%, 2-hydroxybenzoimidazole 20%, 6-amino-1,4-phenylpropanedioxane 35%, methyl silicone oil 0.06%, 2-amino imidazolinone 1.1%. Prepare the high-efficiency desulfurization ether and thiophene solvent prepared above in proportion to a 55wt% solution with water, and fill it into an absorption tower of a high-efficiency removal of sulfide and thiophene system for the removal of sulfide and thiophene from raw gas .

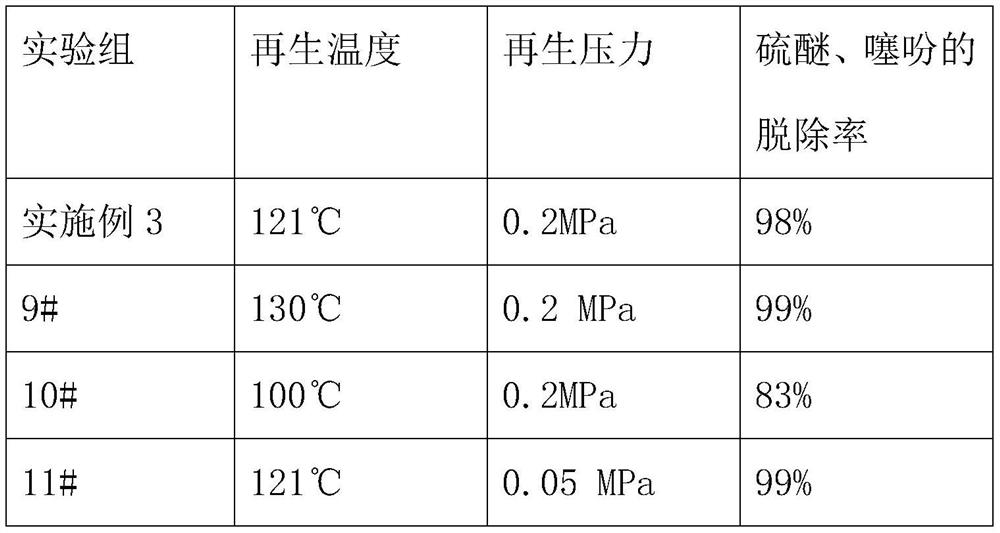

[0060] The absorbent-rich liquid obtained after absorption is flashed through the flash tower, and the obtained semi-lean liquid enters the lean-rich liquid heat exchanger for heat exchange and then enters the regeneration tower for regeneration. The regeneration temperature is 121°C and the regeneration pressure is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com