Gas bearing substrate-loading mechanism process

A substrate and gas technology, applied in the direction of conveyors, electrical components, conveyor objects, etc., can solve problems such as not being raised

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

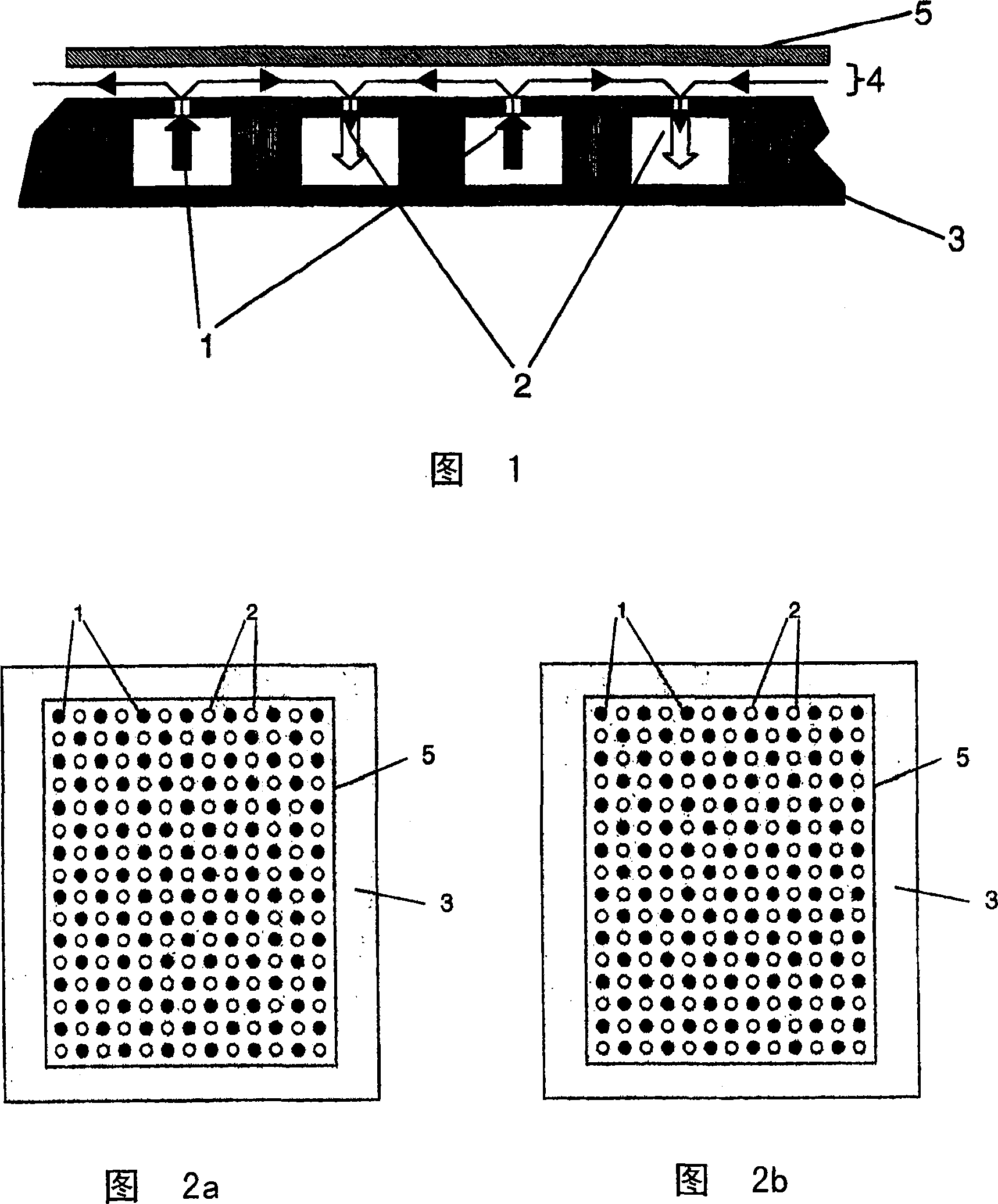

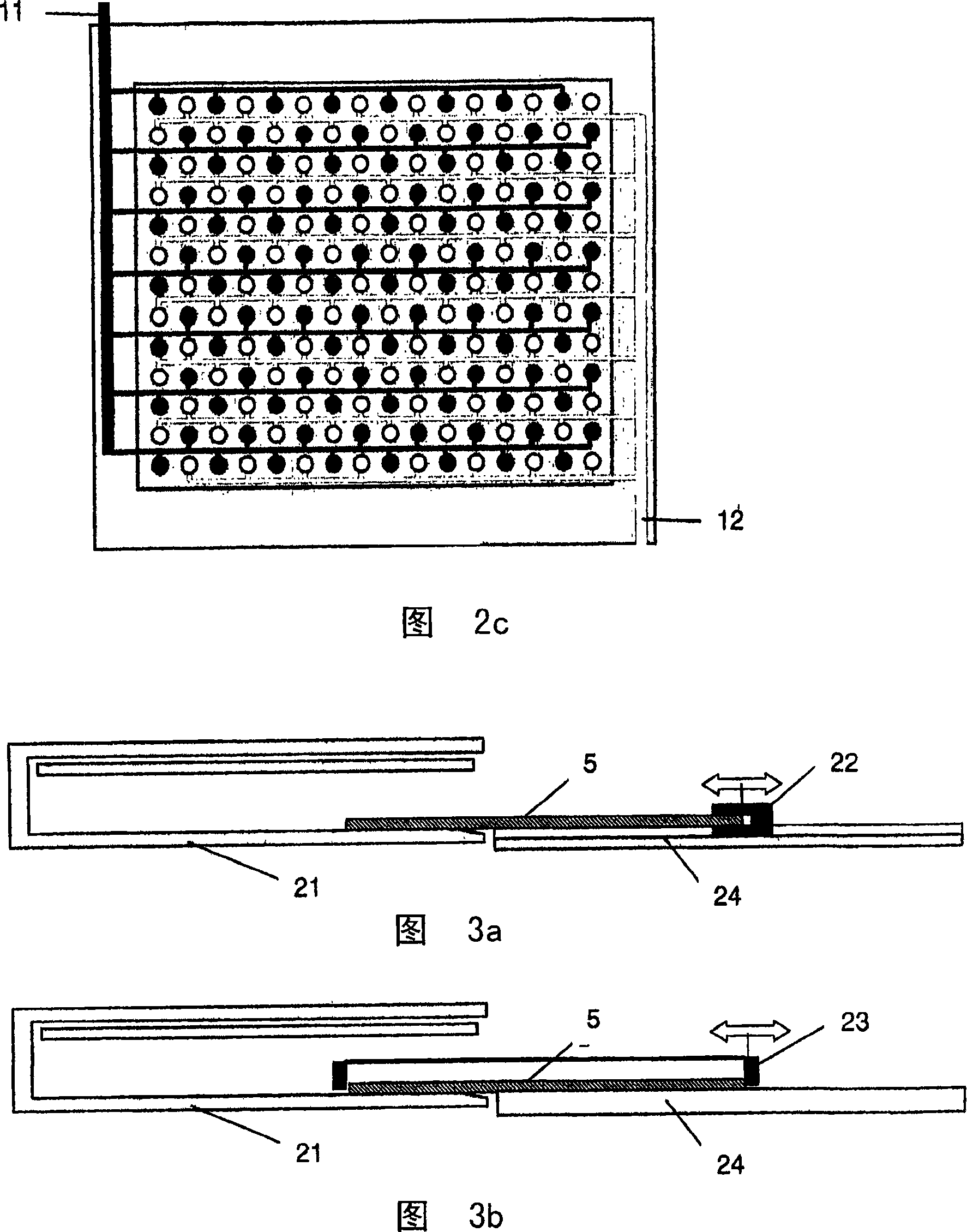

[0018] Example 1: Loading / unloading action by nitrogen injection, density 2700kg / m 3 A glass substrate having a thickness of 0.5 mm was suspended with a pressure of 100 Pa in the injection tank, a pressure of 50 Pa under the substrate and a pressure of 20 Pa in the suction tank.

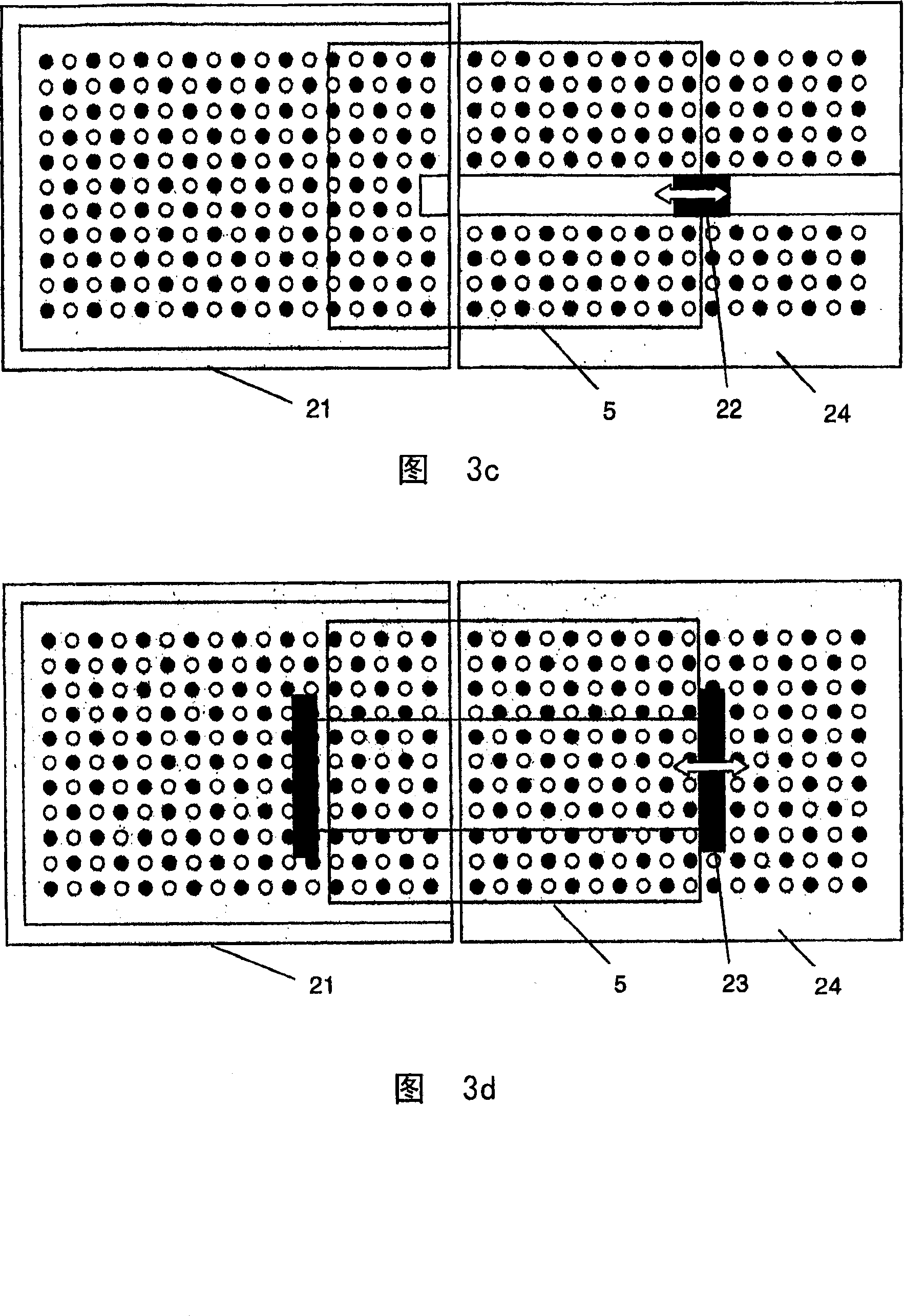

[0019] Because suction cups cannot be used in a vacuum, Figures 3a and 3b show a robotic device with a robotic table 24 with a clamping system 22 (clamps), in a preferred embodiment, once the aforementioned air cushion Levitating the substrate 5, the robotic table 24 is used to move the substrate 5, eg, into and out of the chamber (chamber bottom 21). Due to the suspension of the base 5 and because the loading and unloading movements take place in a substantially horizontal plane, only a small force is required to overcome the inertia of the base to move it to the final loading and unloading position. Alternatively, if the substrate is thick enough and rigid enough, the substrate can also be pushed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com