Packing belt and manufacturing method thereof

A production method and packing belt technology, which are applied in the field of continuous fiber reinforced thermoplastic material packing belt and its production, can solve the problems of poor continuous tension, high elongation and recovery rate, insufficient tensile strength, etc., and achieve good continuous tension , high strength, low elongation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

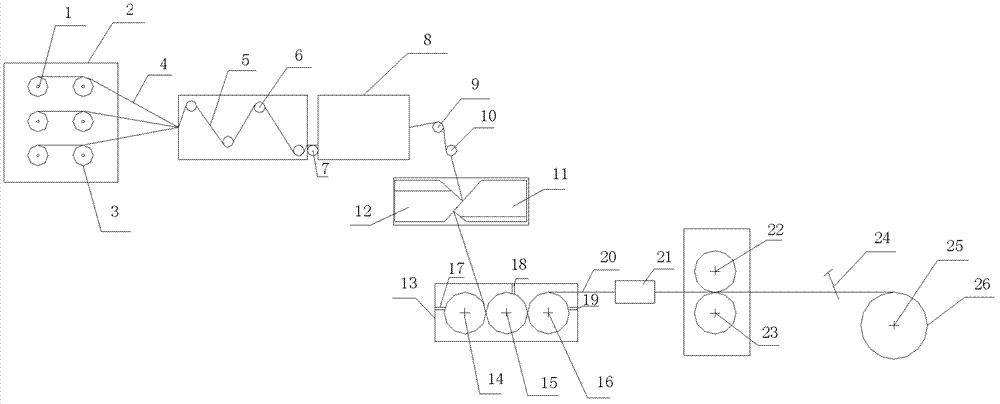

Embodiment 1

[0021] A packing belt made of continuous fiber reinforced thermoplastic material, wherein the continuous fiber is continuous basalt fiber, and the thermoplastic resin is linear low-density polyethylene. The preparation method includes the following steps: the creel 2 is set on the spindle support 1, the continuous fiber roll 3 is wound on the creel 2, and the continuous fiber bundle 4 is drawn out. The continuous basalt fiber bundle 4 is drawn from the continuous fiber roll 5 on the creel 2 and spread by the tension roller 6, and enters the preheating device 8 through the conveying roller 7. , the left die head 12, the continuous double extrusion die head can be opened and closed and pre-impregnated with molten linear low-density polyethylene, the temperature of pre-impregnation is 250 ℃, and then the first impregnated calender roll 14, the second impregnated calender roll 15. The third impregnated calender roll 16 is impregnated and preliminarily shaped to form a continuous b...

Embodiment 2

[0023] A packing belt made of continuous fiber reinforced thermoplastic material, wherein the continuous fiber is continuous glass fiber, and the thermoplastic resin is polypropylene. Its preparation method includes the following steps: the continuous glass fiber bundle 4 is drawn from the continuous glass fiber roll 5 on the creel 2 and spread by the tension roller 6, and enters the preheating device 8 through the conveying roller 7, and the temperature of the preheating device 8 rises to 220 ℃, and then introduced into the right die head 11, left die head 12, continuous double-extrusion die head and molten thermoplastic resin for pre-impregnation, the temperature of pre-impregnation is 270 °C, and then introduced into the impregnated first impregnated calender roll 14. The second impregnated calender roll 15 and the third impregnated calender roll 16 are impregnated and preliminarily shaped to form an impregnated continuous glass fiber belt 20, impregnated with the first impr...

Embodiment 3

[0025] A packing belt made of continuous fiber reinforced thermoplastic material, wherein the continuous fiber is continuous aramid fiber, and the thermoplastic resin is nylon 6. The preparation method includes the following steps: the continuous aramid fiber bundle 4 is drawn out from the continuous aramid fiber roll 5 on the creel 2 and spread by the tension roller 6, and enters the preheating device 8 through the conveying roller 7, and the temperature of the preheating device 8 is Rise to 240°C, and then introduce the right die head 11, the left die head 12, the continuous double extrusion die head and the molten thermoplastic resin are pre-impregnated, the temperature of the pre-impregnation is 280°C, and then the first impregnation The impregnated calender roll 14, the second impregnated calender roll 15, and the third impregnated calender roll 16 are impregnated and initially shaped to form a continuous aramid fiber strip 20 after impregnation, and the first impregnated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com