Processing method of residual oil with high calcium and nitrogen content and high viscosity

A processing method and high-viscosity technology, applied in the petroleum industry, hydrotreating process, processing hydrocarbon oil, etc., can solve the problems of high activity of deironization and decalcification catalyst, hardening of catalyst bed, inability to guarantee long-term operation of the device, etc. Achieve the effect of reducing coke yield, reducing coke generation and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

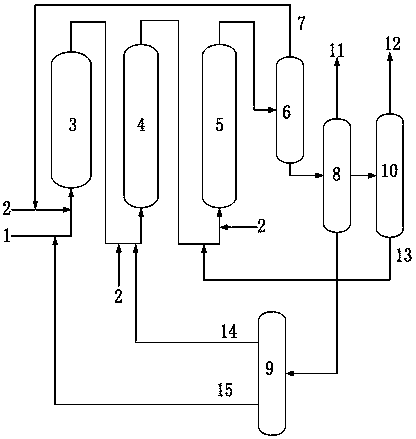

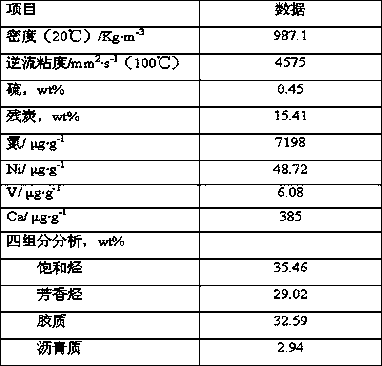

[0033] use figure 1 In the process shown, the properties of the raw material oil are shown in Table 1, and the reaction conditions and experimental results of the suspension bed reactor, the first ebullating bed reactor and the second ebullating bed reactor are shown in Table 2.

[0034] The preparation process of the catalyst used in the suspended bed reactor: (1) Weigh 100g of pseudoboehmite and 100g of kaolin, acidify with 2mol / L nitric acid solution to make the solid content 20~40%, in the spray drying device Spray molding was carried out on the surface, the formed particles were dried at 120°C for 4 hours, and roasted at 850°C for 6 hours. After sieving, the particles with a size of 10-50 μm were selected for use. (2) Weigh 11.28g of phosphoric acid, add 450mL of distilled water, then add 12.25g of molybdenum oxide and 5.61g of basic nickel carbonate in sequence, heat and stir until completely dissolved, then dilute the solution to 500mL with distilled water to obtain sol...

Embodiment 2

[0037] Same as Example 1, the difference is that the calcination temperature of the suspended bed catalyst carrier is 750°C, and the catalyst property is that the specific surface area is 90m 2 / g, pore volume 0.47mL / g, MoO 3 The NiO content is 2.03%, and the NiO content is 0.60%. The reaction pressure of the suspended bed is 15Mpa. The heavy diesel cycle accounts for 15% of the total feed. The temperature of the ebullated bed second reaction zone is 435°C.

Embodiment 3

[0039] Same as Example 1, the difference is that the suspended bed reaction pressure is 15Mpa, and the property specific surface area of the catalyst in the first ebullating bed reaction zone is 120m 2 / g, the pore volume is 0.73mL / g, the pore volume with a pore diameter of 20-100nm accounts for 48% of the total pore volume, MoO 3 The NiO content is 6.67%, the NiO content is 1.64%, and the spherical particle diameter is 0.1~0.3mm. The wax oil feed amount accounts for 15wt% of the total feed amount of the suspended bed reactor, and the residue oil circulation accounts for 15wt% of the total feed amount.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com