Calcium remover for aluminum-silicon alloy and preparation method thereof

A technology of decalcifying agent and silicon alloy, which is applied in the field of metal materials, can solve the problems of environmental pollution, large amount of addition, reduction, etc., and achieve the effects of simple preparation process, promotion of precipitation, and good process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

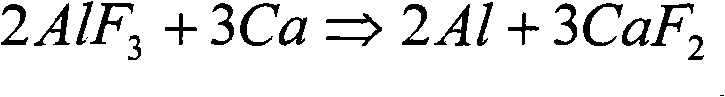

Method used

Image

Examples

Embodiment 1

[0018] (1) Press AlF first 3 60%, Ni-Si-B master alloy 35%, carbon powder 5% mass ratio to weigh raw materials;

[0019] (2) Ni-Si-B master alloy is subjected to rapid solidification argon atomization treatment to obtain a granular Ni-Si-B master alloy with a particle size of 0.5 mm;

[0020] (3) AlF 3 Powder, 0.5mm granular Ni-Si-B master alloy and carbon powder are uniformly mixed, and the mixed powder is compacted by a briquetting machine to prepare an aluminum-silicon alloy calcium remover.

[0021] The Ni-Si-B master alloy in the step (1) is composed of nickel, silicon and boron, and the mass percent of each component is: nickel 55, silicon 40, boron 5. An aluminum-silicon alloy calcium remover is obtained according to the above proportioning ratio, and its chemical composition (mass percentage) is: aluminum 19.20, fluorine 40.80, nickel 19.25, silicon 14.00, boron 1.75, and the rest is carbon.

Embodiment 2

[0023] (1) Press AlF first 3 50%, Ni-Si-B master alloy 40%, carbon powder 10% mass ratio to take raw materials;

[0024] (2) Ni-Si-B master alloy is subjected to rapid solidification argon atomization treatment to obtain a granular Ni-Si-B master alloy with a particle size of 0.4mm;

[0025] (3) AlF 3 Powder, 0.4mm granular Ni-Si-B master alloy and carbon powder are uniformly mixed, and the mixed powder is compacted by a briquetting machine to prepare an aluminum-silicon alloy calcium remover.

[0026] The Ni-Si-B master alloy in the step (1) is composed of nickel, silicon and boron, and the mass percentages of each component are: 60 nickel, 30 silicon and 10 boron. Obtain a kind of aluminum-silicon alloy calcium remover of optimal composition according to above-mentioned proportion, and its chemical composition (mass percentage) is: aluminum 16, fluorine 34, nickel 24, silicon 12, boron 4, and the rest is carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com