Detecting method and detecting device of surface-shape error of double curved surface convex reflecting mirror

A convex reflector and reflector surface technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of large system errors, difficult manufacturing and processing of detection devices, and high cost, and achieve a simple structure, easy to manufacture, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following embodiments are given in conjunction with the accompanying drawings to further describe in detail the surface error detection device and detection method of the hyperbolic convex mirror of the present invention.

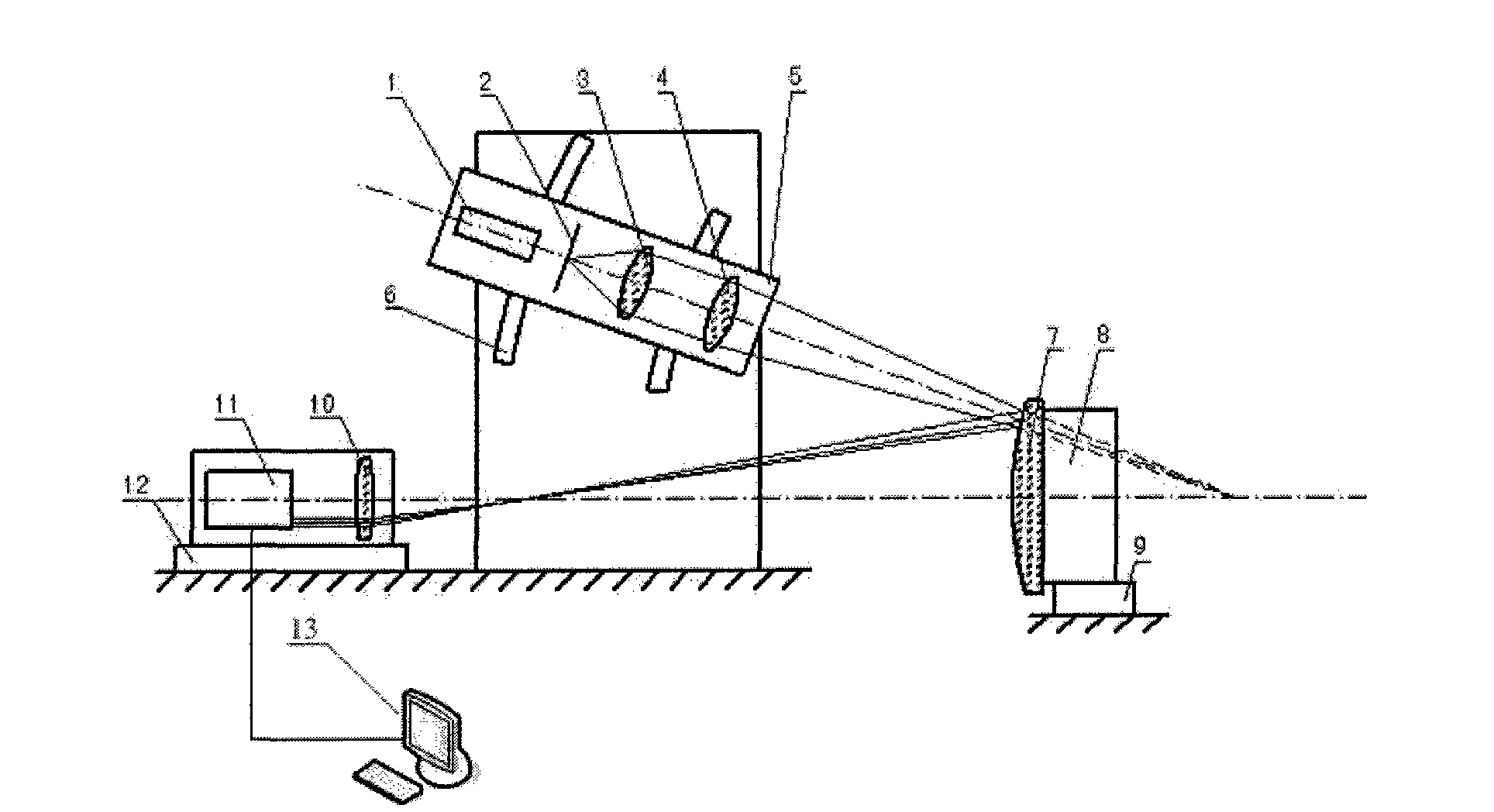

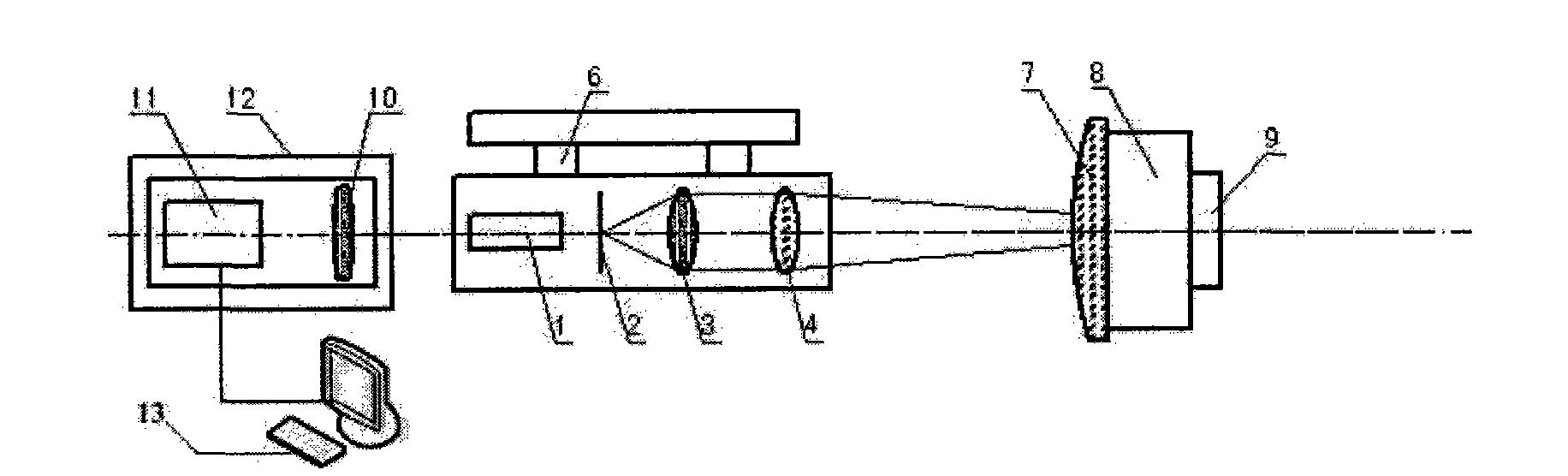

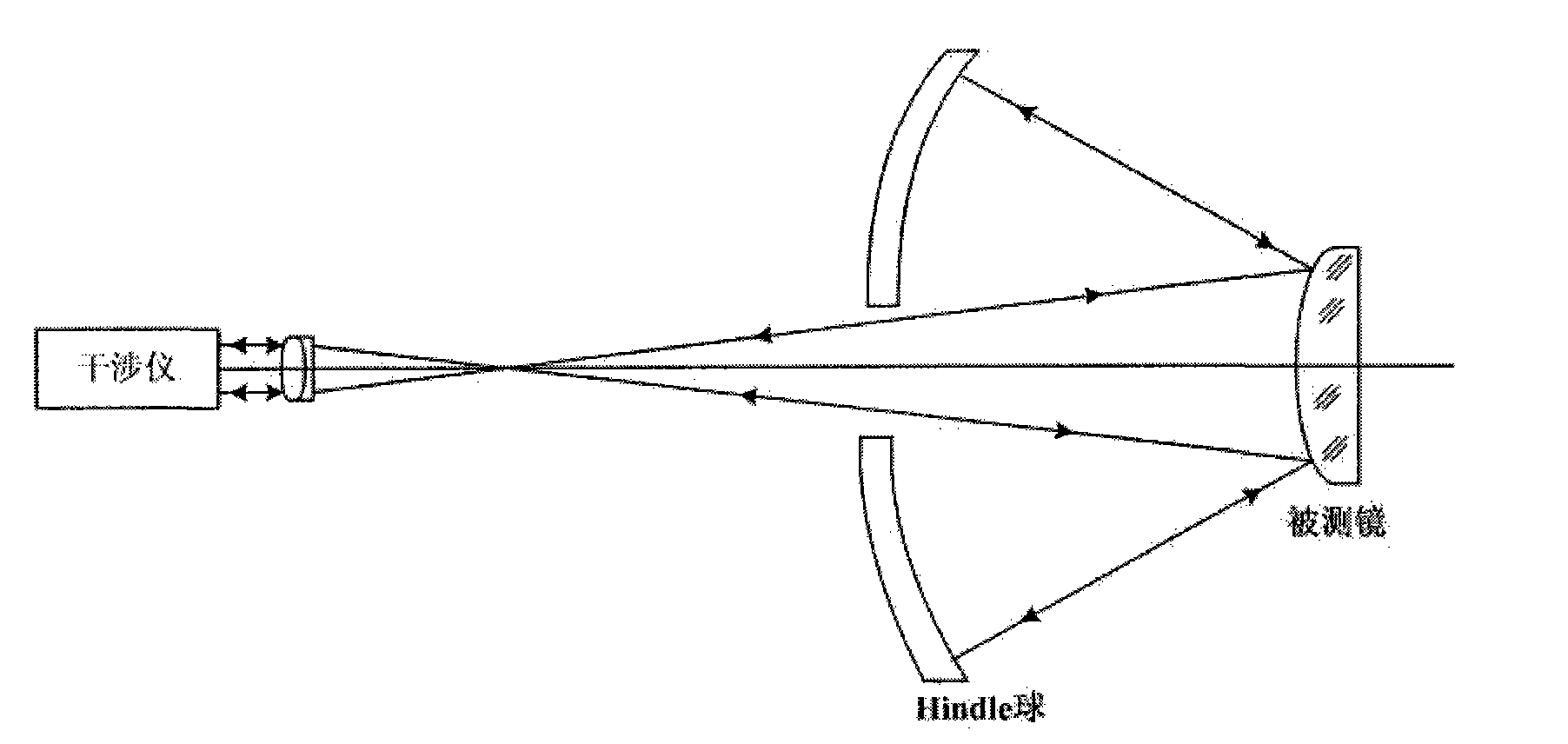

[0024] refer to figure 1 , 2, a hyperboloid convex reflective mirror surface shape error detection device, including an indexing turntable 8 mounted on a sliding table 9 to clamp a hyperboloid convex reflective mirror 7 to be tested, a light source 5 emitting a laser convergent light beam without aberration, respectively A Shack-Hartmann wavefront detector 11 and an aberration-eliminating collimator lens 10 arranged on a sliding platform 12, a computer 13 connected with the Shack-Hartmann wavefront detector 11; the rotating shaft of the indexing turntable 8 That is, the optical axis of the measured hyperboloid convex reflector 7 mounted on the indexing turntable 8; the light source 5 is arranged on the arc-shaped guide rail 6, and the focus of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com