Method and device for polishing small-bore optical element

A technology for optical components and polishing devices, applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of difficult access of polishing tools, narrow processing space, low shear stress, etc., to achieve enhanced material removal rate, increased contact opportunities, The effect of improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

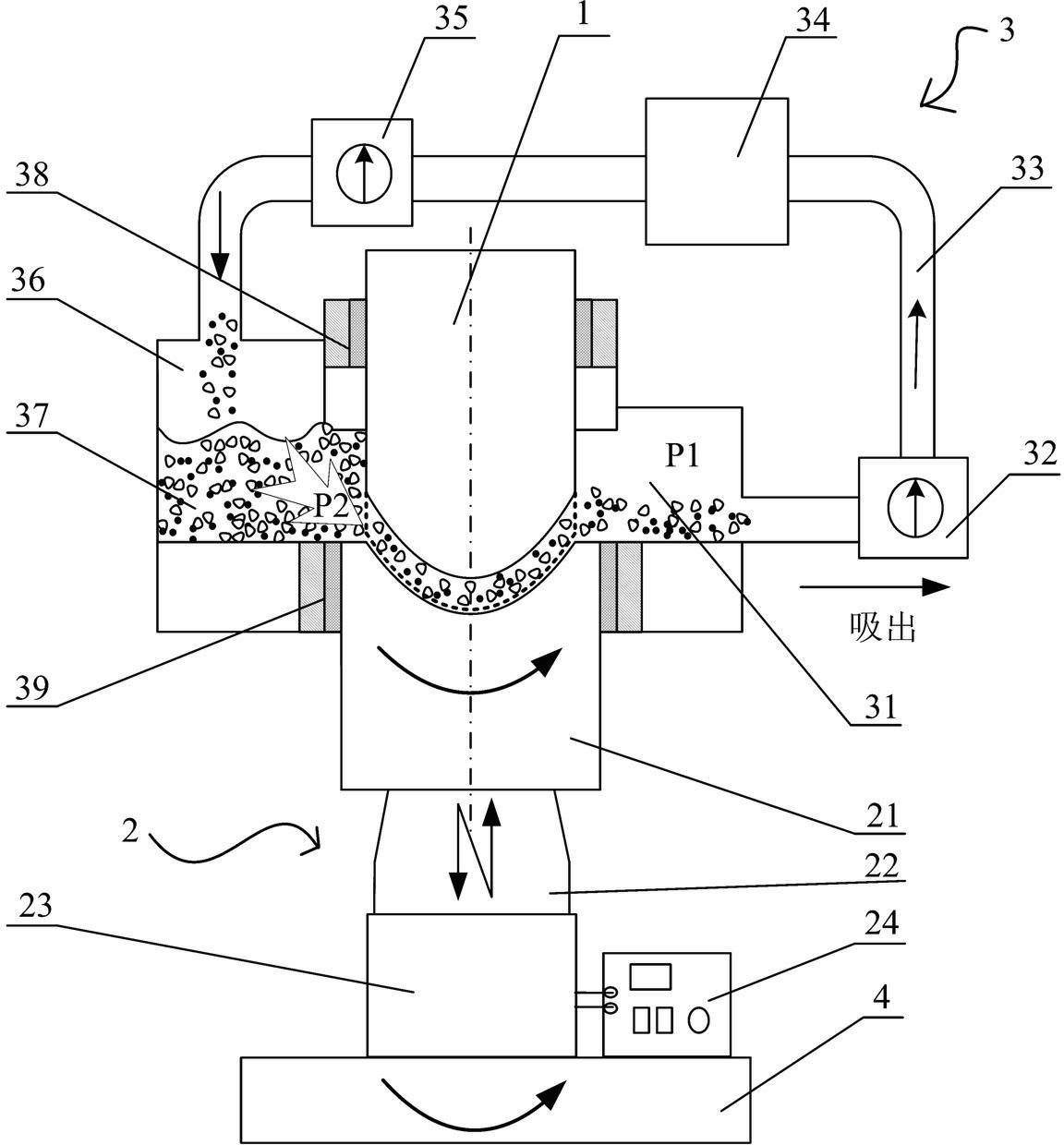

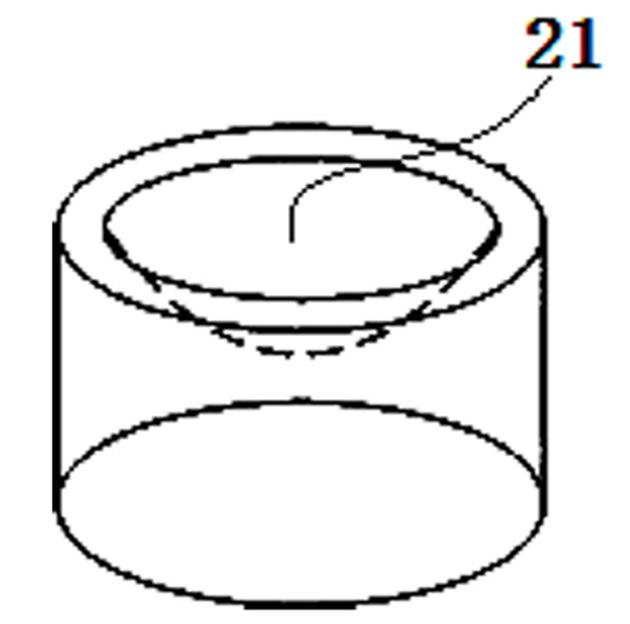

[0040] A small-caliber optical element polishing device, such as figure 1 As shown, it includes a micro polishing groove 14 formed by an axisymmetric rotating curved surface workpiece 21 and the concave surface of the restrictor block 1, a negative pressure groove 31, a suction pump 32, a circulation pipeline 33, a liquid reservoir 34, a press pump 35, a high pressure The groove 36, the upper sealing device 38 and the lower sealing device constitute the entire micro-abrasive fluid circulation system 3; the ultrasonic vibration system 2 is fixedly connected with the rotating platform 4; the bottom of the axisymmetric rotating curved surface workpiece 21 is installed on the horn 22 to vibrate up and down, The upper end of the axisymmetric rotating curved surface workpiece 21 is connected with the high pressure groove 36 and the negative pressure groove 31 through the lower sealing device 39, and the sealing effect is maintained during the working rotation and vibration; the flow ...

Embodiment 2

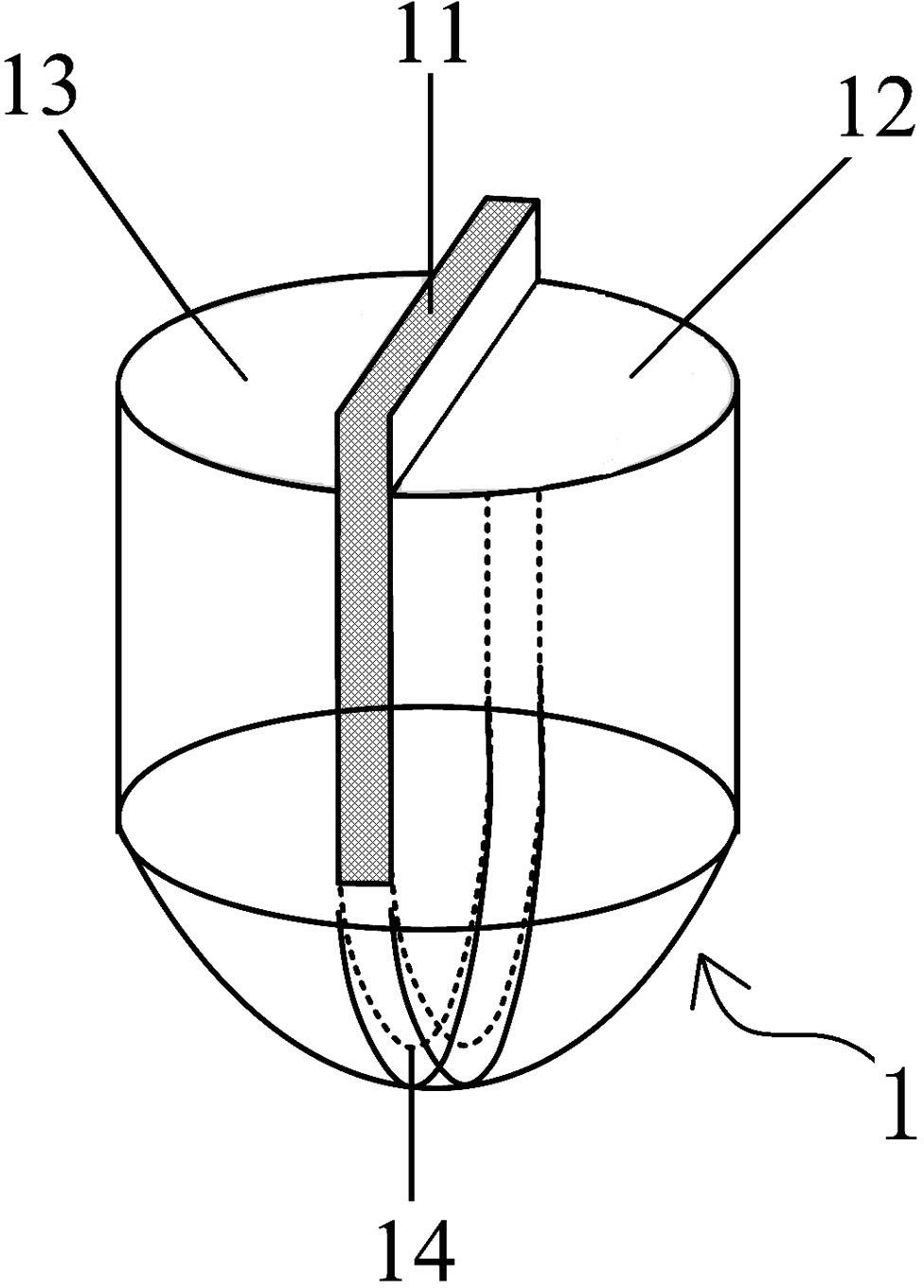

[0049] A small-caliber optical element polishing device, see attached Figure 4 , in this embodiment, the small-diameter axisymmetric rotating convex workpiece 21 is fixed on the horn 22 of the ultrasonic system 2 with a fixture, and the concave adjustment in the axisymmetric rotating convex surface of the workpiece and the flow limiting block 1 with the groove path is adjusted. The gap between the plates 11 is in the range of 0.3mm-1mm, the concave surface of the front stopper 12 and the rear stopper 13 in the restrictor 1 matches the convex shape of the axisymmetric rotational surface to be processed, so that the adjustment plate 11 A tiny polishing groove 14 is formed in the middle of the axisymmetric rotating curved surface; the device structure and processing method of other parts are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com