Four-layer water capsule used for cigarettes and manufacturing method of four-layer water capsule

A technology for water capsules and cigarettes, applied in the field of four-layer water capsules for cigarettes and its preparation, can solve the problems of low efficiency, easy adhesion, strong viscosity of waxy materials, etc., and achieve the effects of improved pressure resistance and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to the ratio listed in Table 1, 500ml of the preparation materials for the four-layer water capsules were added to the four interlayer tanks and stirred, and the steam interlayer was heated to 80°C to melt it, and kept for 1 hour. Use the DWJSYJ-I type small capsule dropping pill machine to drop the inner layer and the second layer of materials into a container containing 10% calcium chloride aqueous solution as a curing agent, and cure for 20 minutes. Then put the cured and shaped capsules in the reaction tank filled with the third layer of materials for 1 minute, take them out and place them in water at a temperature of 10° C. to condense and shape them. Finally, soak the three-layer water capsule in 2% sodium alginate aqueous solution, then drop it into 5% calcium chloride aqueous solution through the corresponding mold, solidify for 10 minutes, take it out, wash and dry to obtain the four-layer water-for-cigarette capsule.

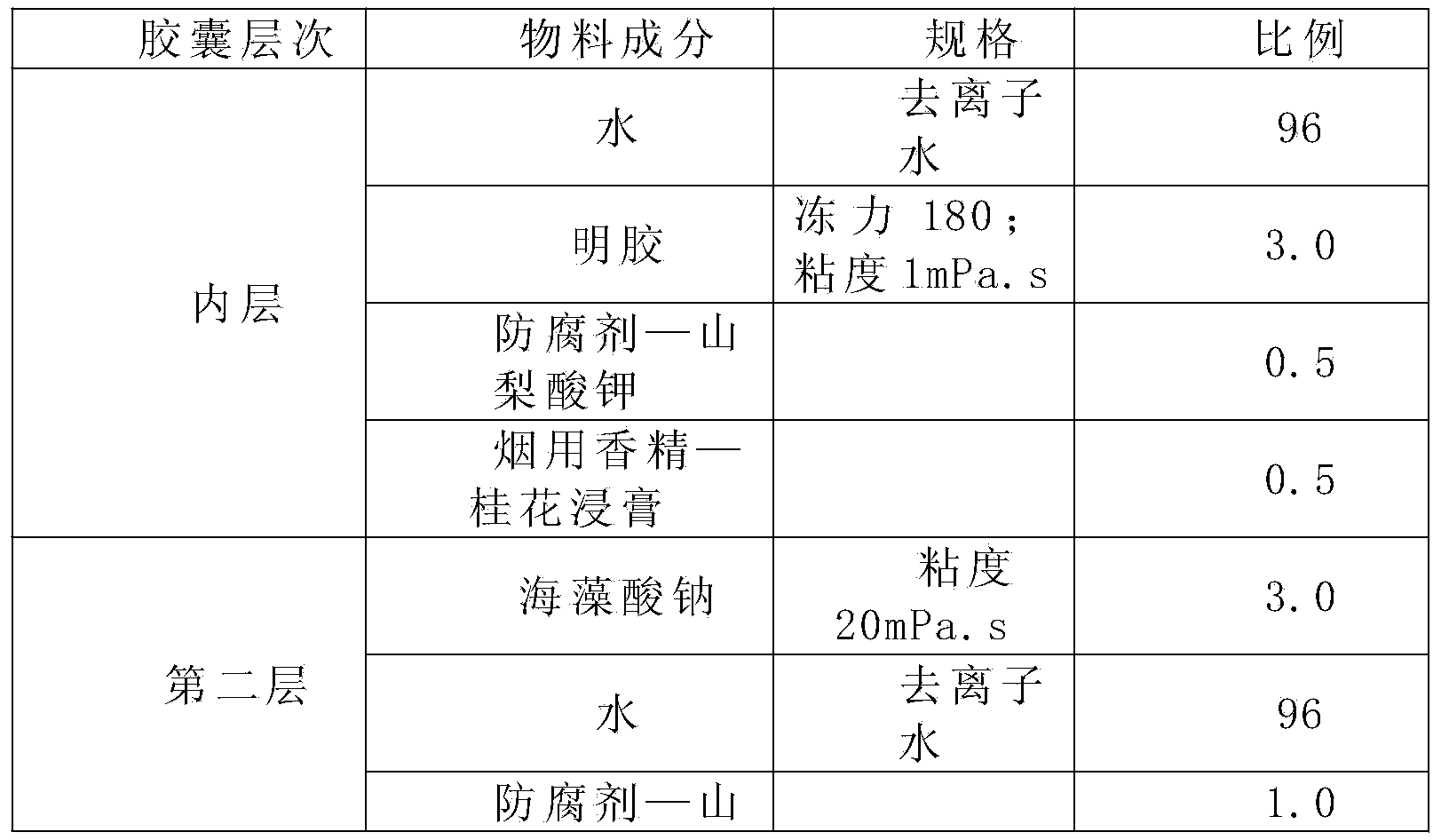

[0021] Table 1 material ratio ...

Embodiment 2

[0026] According to the ratio listed in Table 2, 500ml of the preparation materials for the four-layer water capsules were added to the four interlayer tanks and stirred, and the steam interlayer was heated to 90°C to melt it, and kept for 2 hours. Use the DWJSYJ-I type small capsule dripping machine to drop the inner layer and the second layer of materials into a container containing 20% calcium chloride aqueous solution as a curing agent, and cure for 10 minutes. Then put the cured and shaped capsules in the reaction tank filled with the third layer of materials for 2 minutes, take them out and place them in water at a temperature of 0°C to condense and shape them. Finally, soak the three-layer water capsule in 1% sodium alginate aqueous solution, then drop it into 5% calcium chloride aqueous solution through the corresponding mold, solidify for 10 minutes, take it out, wash and dry to obtain the four-layer water-for-smoking capsule.

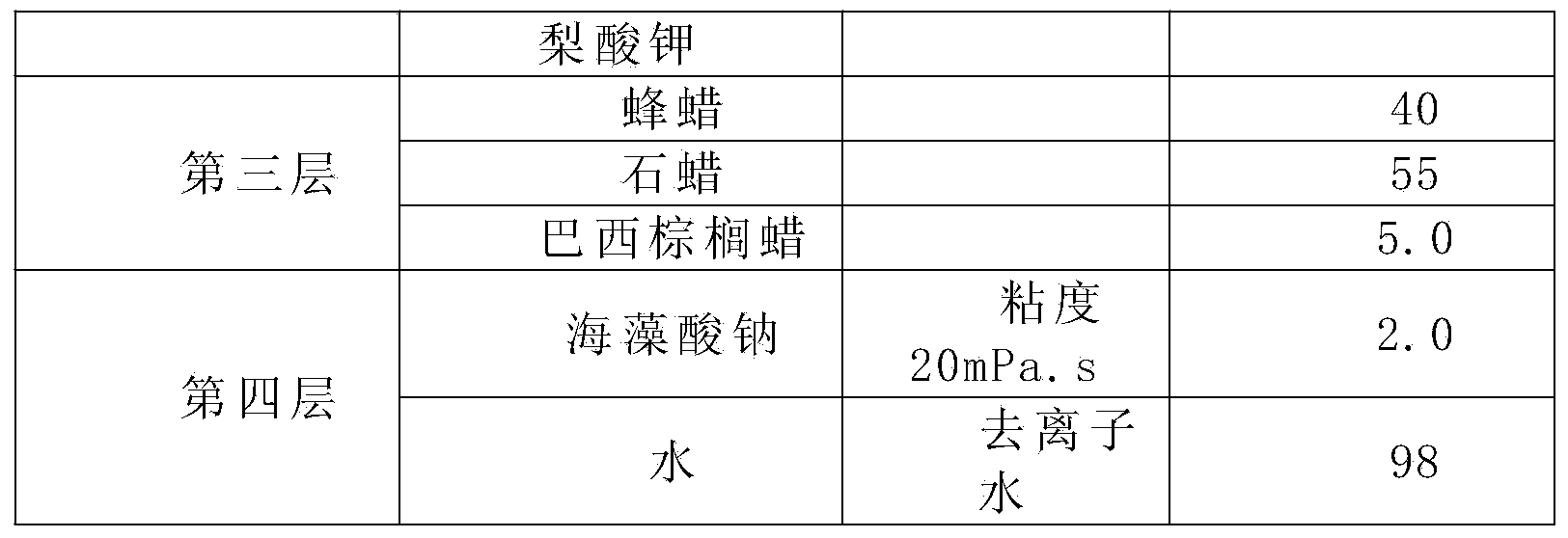

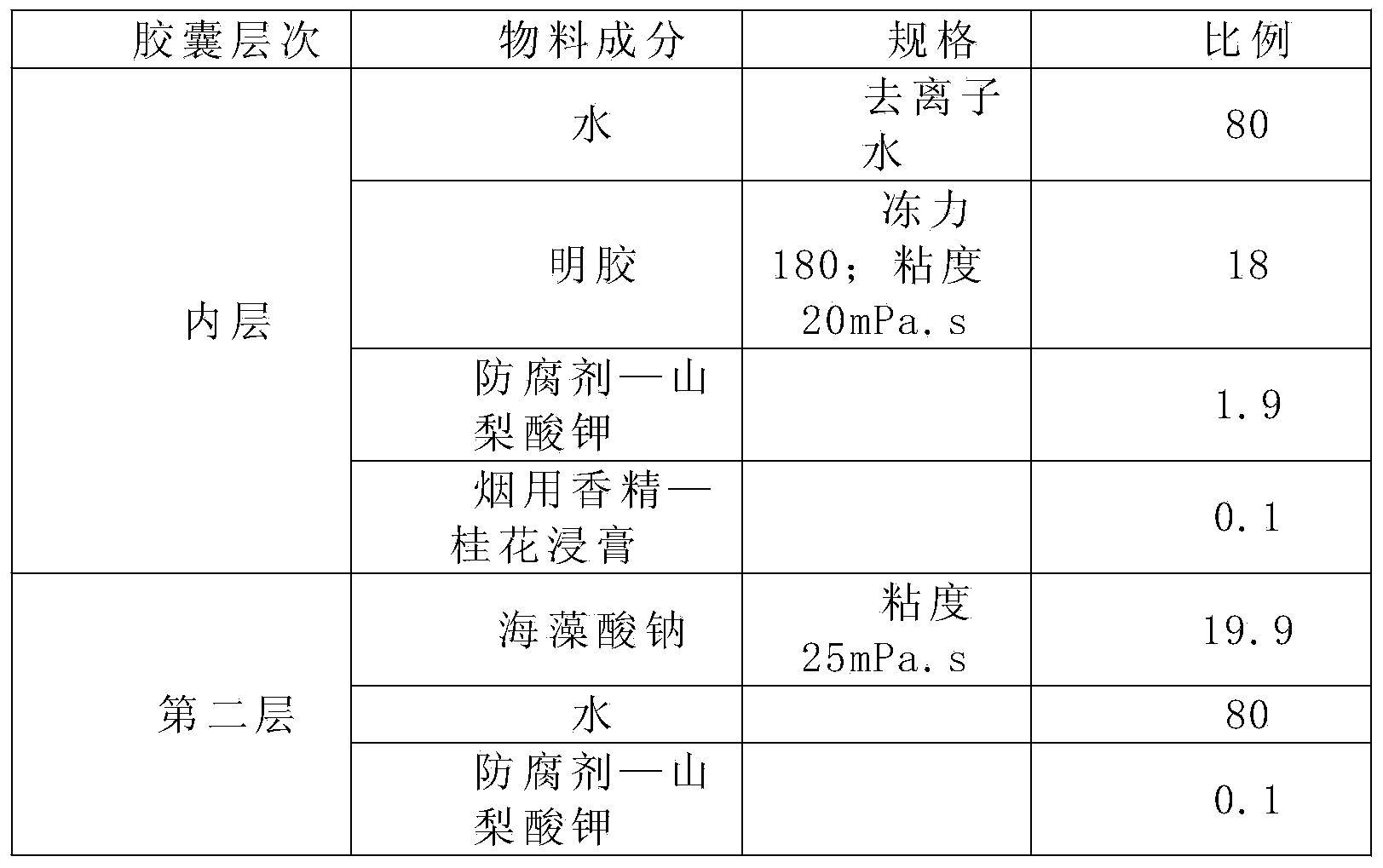

[0027] Table 2 Material Proportion

...

Embodiment 3

[0032] According to the ratio listed in Table 1, 500ml of the preparation materials for the four-layer water capsules were added to the four interlayer tanks and stirred, and the steam interlayer was heated to 80°C to melt it, and kept for 1 hour. Use the DWJSYJ-I type small capsule dropping pill machine to drop the inner layer and the second layer of materials into a container containing 10% calcium chloride aqueous solution as a curing agent, and cure for 20 minutes. Then put the cured and shaped capsules in the reaction tank filled with the third layer of materials for 1 minute, take them out and place them in water at a temperature of 10° C. to condense and shape them. Finally, soak the three-layer water capsule in 2% sodium alginate aqueous solution, then drop it into 5% calcium chloride aqueous solution through the corresponding mold, solidify for 10 minutes, take it out, wash and dry to obtain the four-layer water-for-cigarette capsule.

[0033] Table 1 material ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com