Coating method for DLC (diamond-like carbon) coating on spinning reed and equipment

A reed and coating technology, applied in the field of DLC coating coating, can solve problems affecting product quality, low quality of textile products, and affecting production efficiency, so as to improve the performance and service life of reed, ensure the quality of textile products, and save The Effect of Textile Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

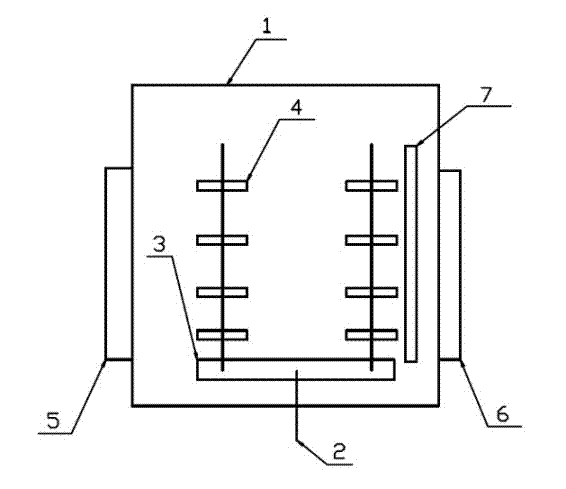

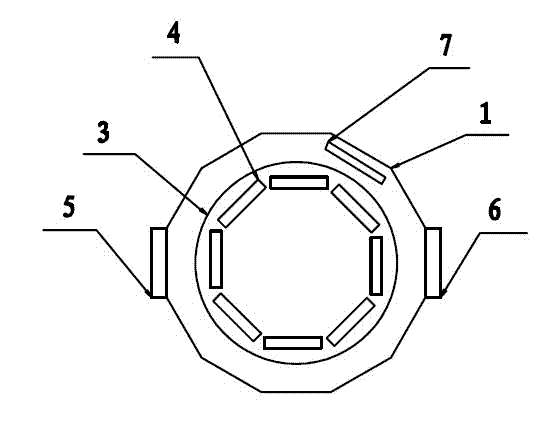

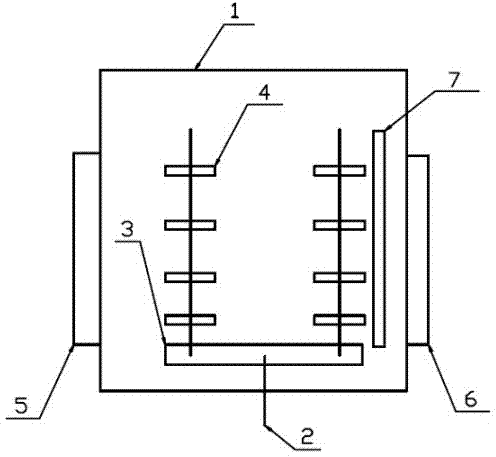

[0028] Currently commonly used PVD coating technology is mainly divided into three categories, vacuum evaporation coating, vacuum sputtering coating and vacuum ion coating. Among them, the vacuum sputtering coating is to bombard the solid surface with high-energy particles, so that the solid surface particles gain energy and escape the surface, and deposit on the substrate. Vacuum ion coating means that in a vacuum environment, the introduced gas is ionized under the combined action of the electromagnetic field of the ion source, and the ionized ions are accelerated under the action of the electric field formed by the bias voltage applied to the substrate, and the ionized ions are formed as high-energy particles. The form of bombardment or deposition on the substrate, so as to complete the process of ion etching cleaning and ion beam deposition. The multi-arc ion beam technology of the present invention is a unique and efficient DLC coating technology, which will be described ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com