Production process of superfine dry-particle ceramic large plate and product of same

A production process and dry granulation technology, which is applied in the field of architectural ceramics, can solve the problems of poor anti-skid effect and poor wear resistance, and achieve the effects of improving anti-skid, chemical corrosion resistance, and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

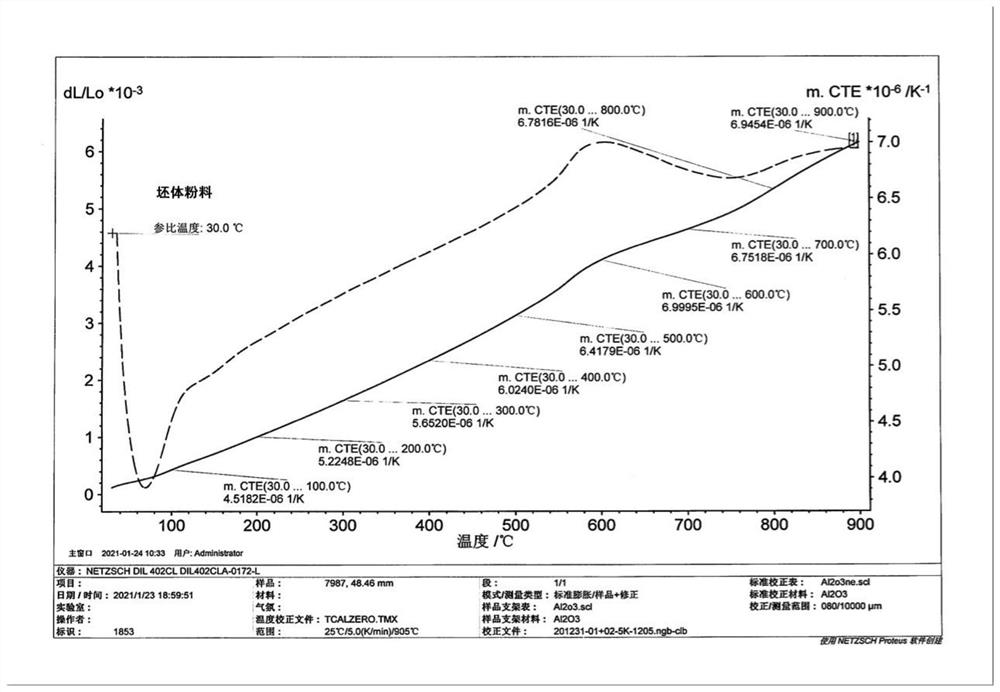

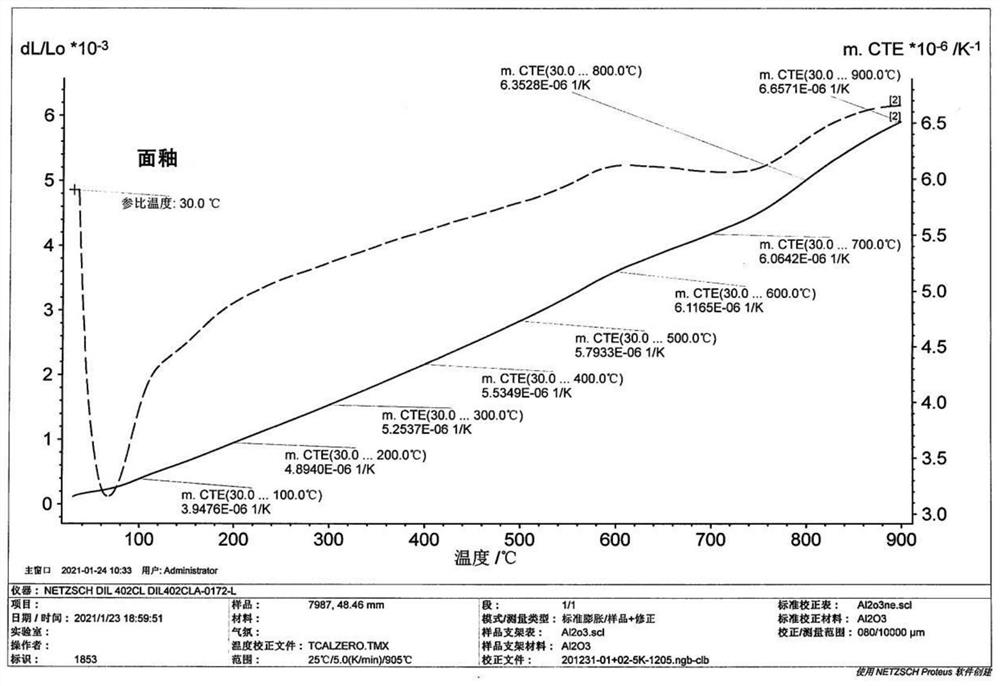

[0079] A kind of production technology of superfine dry grain ceramic slab, comprises the following steps:

[0080] (1) Carry out brushing and water spraying wetting treatment on the green body, wherein the amount of water spraying is 8g / (350×350mm);

[0081] (2) Surface glaze and inkjet printing are sequentially applied on the surface of the green body;

[0082] (3) drench the dry glaze slurry on the surface of the green body obtained in the step (2), the flow rate is 30-36s, the amount of glaze is 28-32g / (350×350mm), and the dry glaze slurry is drenched Afterwards, the green body is dried, the temperature is controlled at 200° C., and the weight percentage of the dry body after drying is 0.8%.

[0083] In parts by weight, the dry granule glaze slurry includes 110-130 parts of suspending agent, 35-45 parts of superfine dry granules and 4.5-11 parts of raw material transparent glaze, wherein, by mass ratio, the superfine dry granules comprise 5-10% Nanoscale corundum powder,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com