Antistatic pad and tray as well as manufacturing method thereof

A manufacturing method and anti-static technology, applied in chemical instruments and methods, containers, coatings, etc., can solve the problems of reducing production efficiency, physical properties such as extensibility, etc., to improve production efficiency, excellent anti-static properties, and resistance to Good grinding and forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

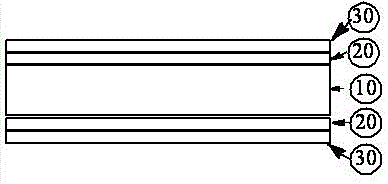

[0050] 1-1. Hybrid carbon nanotubes (multiple walls with a length of 30? and a width of 10nm) 2% by weight, acrylic copolymer binder (Carboset CR780, BFGoodrich Co.) 15% by weight, isopropanol 50% by weight, Water 32% by weight, fluidity improver (HPA-538, Yeungsan Co.) 1% by weight, to produce thermosetting antistatic coating liquid.

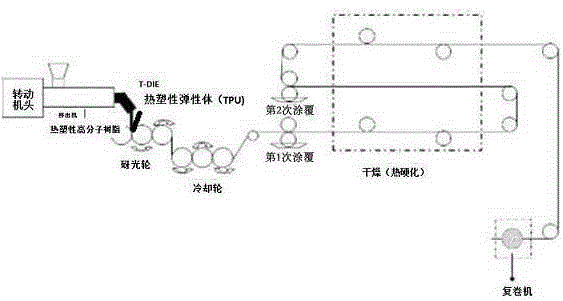

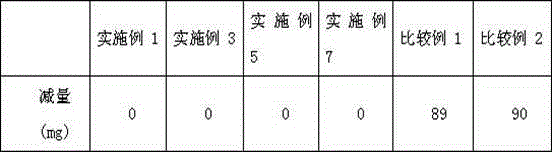

[0051] 1-2. If figure 1 As shown, when the ABS resin is extruded through the T-die extrusion process (the temperature of the extruder is 150 ~ 170°C), the TPU / The antistatic coating solution used in the ABS hybrid antistatic mat is coated with a thickness of 0.3 ? 0.3? Thick coating on the reverse side and heat hardening and coating at 60-80 ℃ temperature, and finally produce an anti-static mat with anti-static coating layers on both sides. Surface resistance passed ASTM D257 method, both sides are 10E6 Ω / ?

Embodiment 2

[0053] The antistatic mat manufactured in the embodiment 1 was vacuum formed at a temperature of 150-180° C. to manufacture an antistatic tray extended 5 times.

Embodiment 3

[0055] Except that instead of the carbon nanotubes in Example 1-1, the conductive polymer [(polyethylene diauxy thiophene)] PEDOT is used, and after the antistatic coating liquid is produced in the same way, the same method as in Example 1-2 is used to produce the antistatic pad. The surface resistance passes the ASTM D257 method, and both sides are 10E6 Ω / ?.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com