Unidirectional flap

A valve and one-way technology, applied in the field of medical devices, can solve problems such as limited gap width, many horn nodes, and damage to the inner wall of the bronchi, and achieve improved support and stability, reduced horn nodes, and reduced occurrence probability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

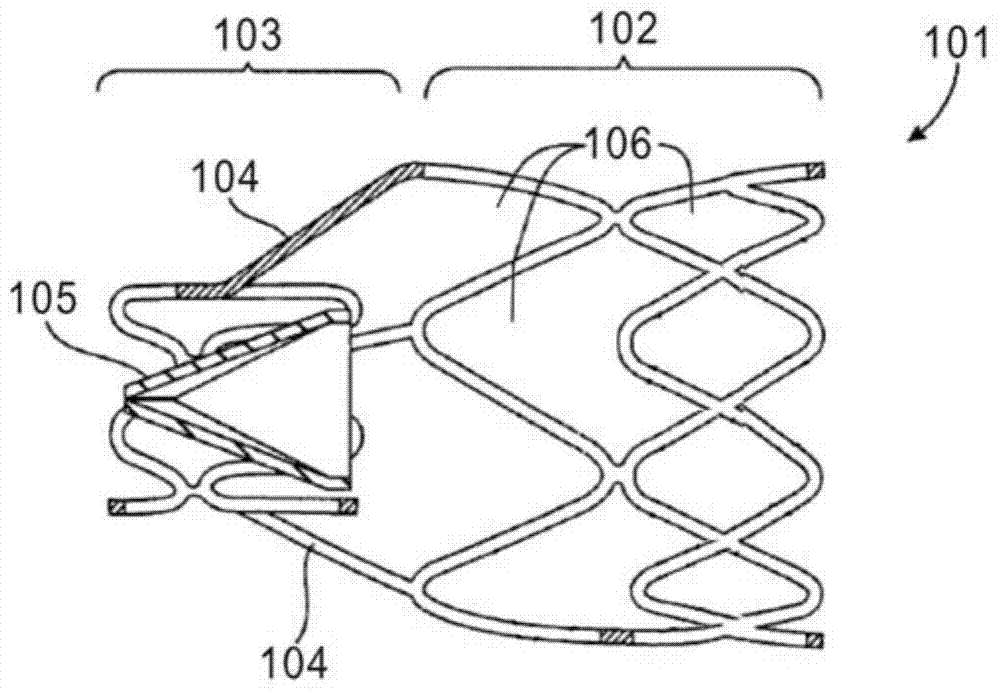

Embodiment 1

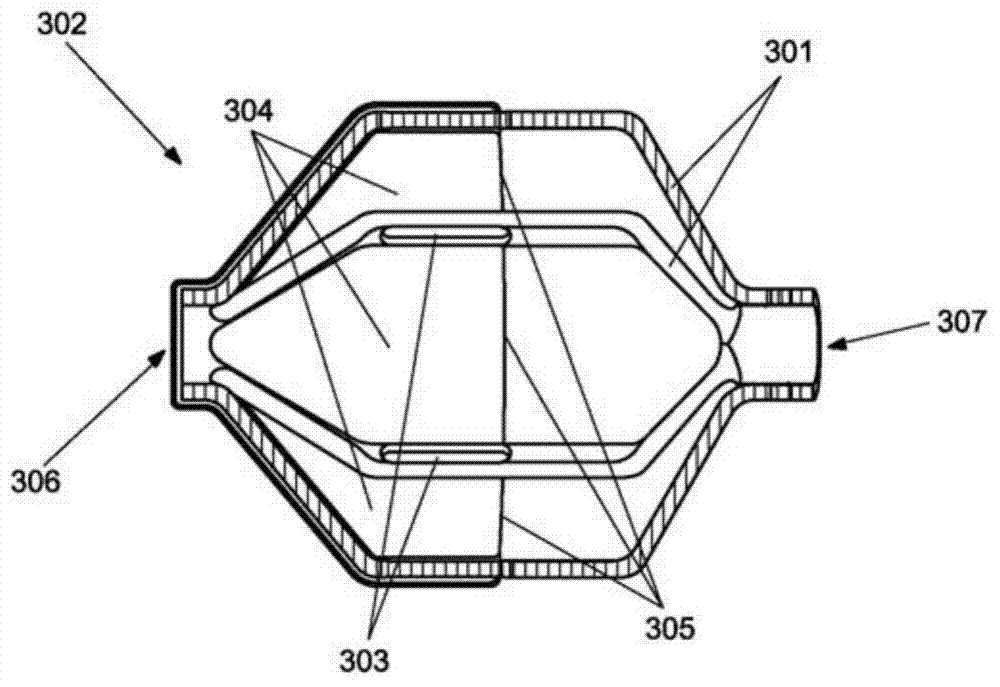

[0058] Such as image 3 As shown, the bronchial valve in Embodiment 1 of the present invention includes a frame 302 and an insulating membrane 304, the frame 302 includes a distal end 306 away from the human oral cavity, a proximal end 307 close to the human oral cavity, and a middle part connecting the proximal end 307 and the distal end 306, The middle part is composed of a plurality of longitudinal beams 301 parallel to the central axis. Both ends of each longitudinal beam 301 are bent at a certain angle and then extended to the near end and the far end to form a closed lantern frame 302; the longitudinal beams 301 are close to The inner and outer surfaces of the distal end 306 are provided with a groove-like coating site 303 (hereinafter referred to as coating groove); the part between the coating groove 303 and the distal end 306 is covered with the insulating film 304 . The edge 305 of the insulating film 304 extends into the coating groove to improve the adhesion of the...

Embodiment 2

[0072] Such as Figure 8 As shown, in this embodiment, in order to enhance the adhesion of the insulating film on the frame 302, a grid 801 is provided at the connection between the frame 302 and the distal end 306. When the instrument is received into the delivery system, the insulating film can be accommodated in the grid, thereby Avoid friction between the barrier film and the delivery system, which also enhances the adhesion of the barrier film on the surface of the device.

[0073] In addition, in order to strengthen the firmness of the target position of the device in the bronchi, a protruding bump is added to the hole-shaped coating site of the stringer 301 (hereinafter referred to as: the coating hole) to increase the friction between the stringer and the bronchi. This prevents displacement of the device within the bronchi. The process of making bumps is as follows: insert a nickel-titanium rod on the film-coated hole 303, and then fix it on the longitudinal beam 301 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com