Micro-cantilever gas sensor and manufacturing method thereof

A technology of gas sensor and micro-cantilever, which is applied in the direction of electrical components, microstructure technology, gaseous chemical plating, etc., can solve the problems of no invention patent application, achieve electrical interconnection and signal output, improve sensitivity, and avoid wet method Effect of Etch and Back Etch Processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

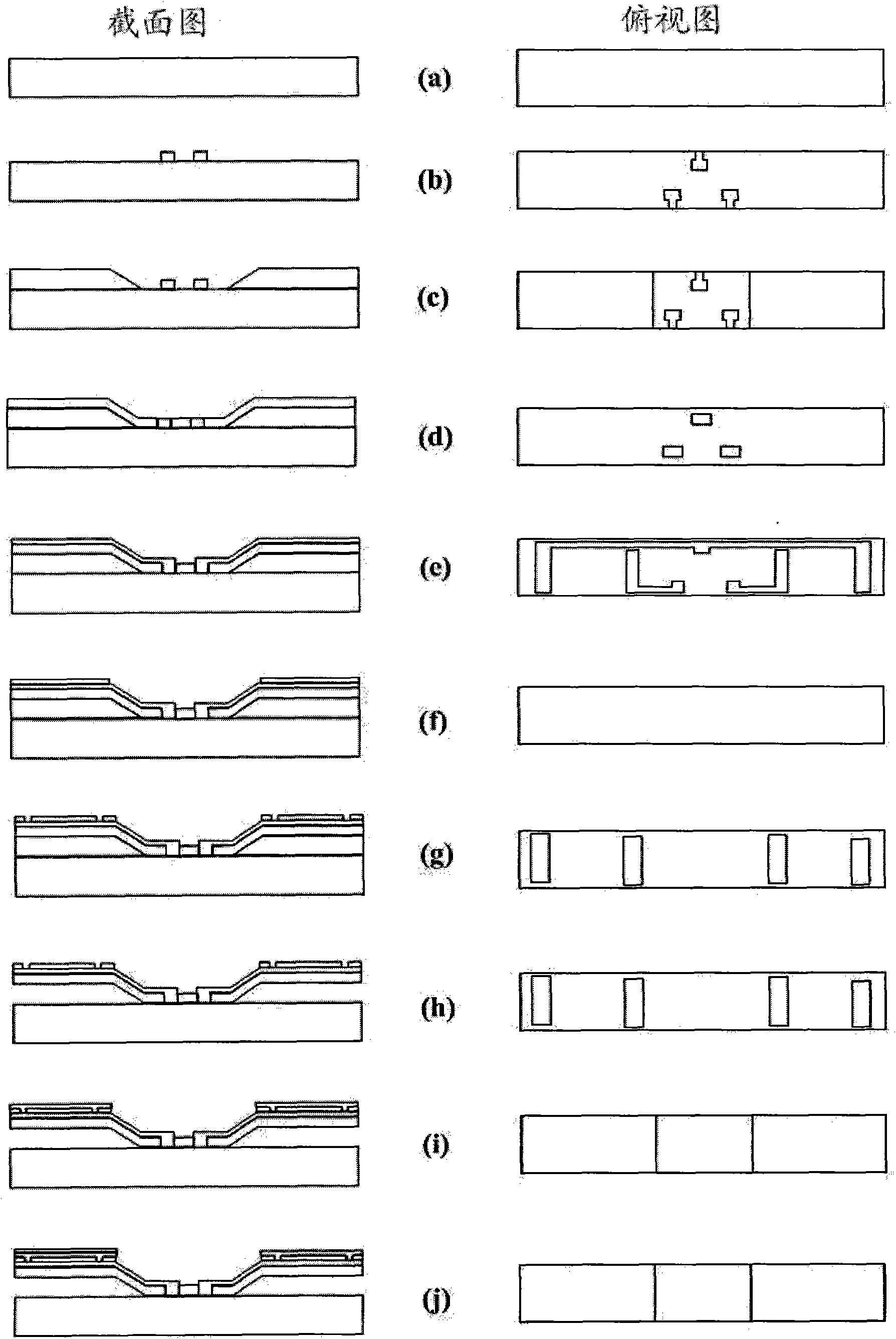

[0032] The present invention will be further described below in conjunction with accompanying drawing:

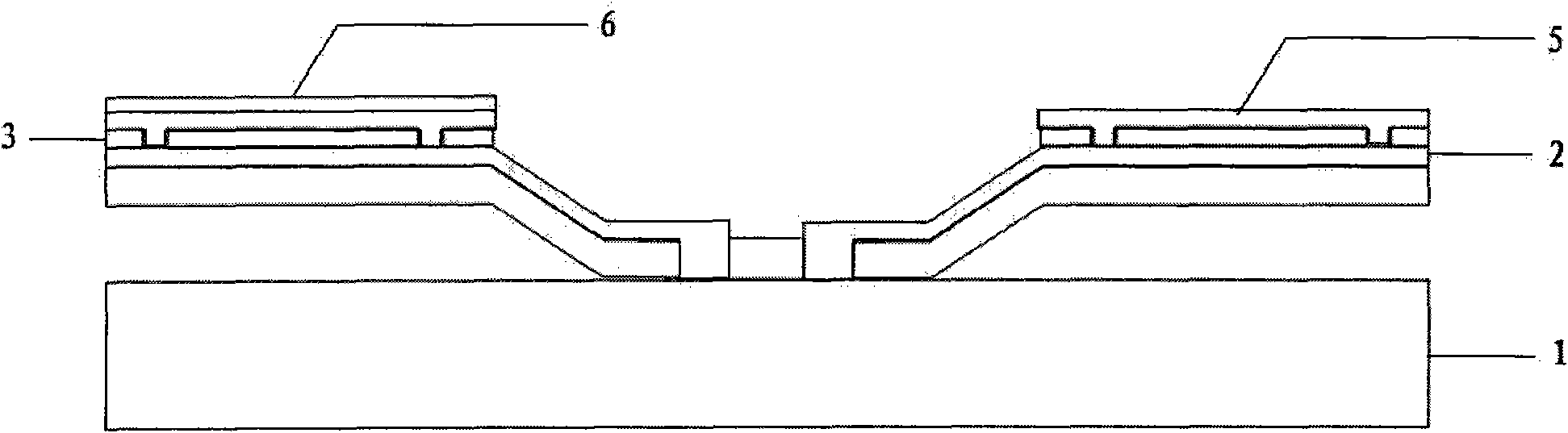

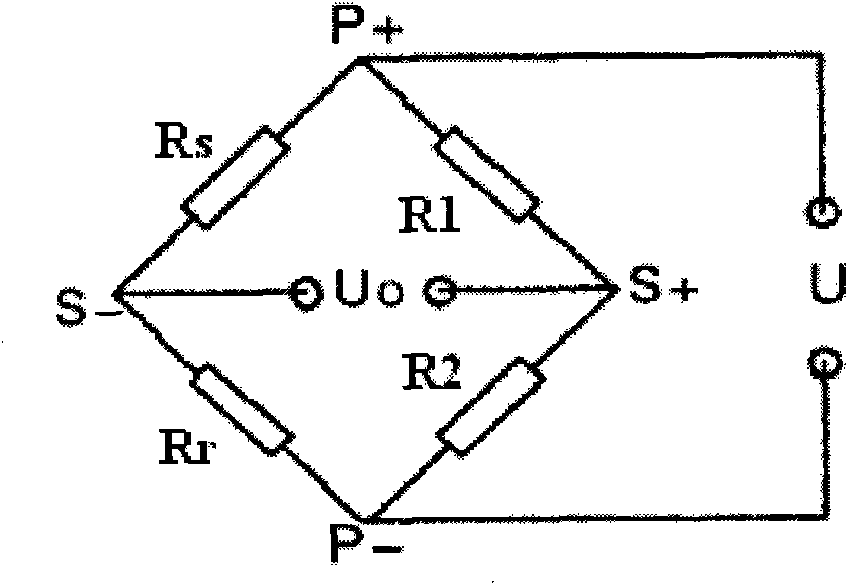

[0033] Such as figure 1 , figure 2 As shown, the present invention belongs to a piezoresistive micro-cantilever sensor, which includes a sensing unit 1, and each group of sensing units 1 includes two micro-cantilever beams, which are respectively a measuring cantilever beam 2 and a reference cantilever beam 3; two micro-cantilever beams with matched resistor R 1 and R 2 Form a Wheatstone bridge 4. The measuring cantilever beam 2 and the reference cantilever beam 3 are connected to the adjacent bridge arms of the Wheatstone bridge 4, corresponding to the Rs resistance and the Rr resistance of the bridge 4 respectively. The reference cantilever beam 3 is mainly used to eliminate the influence of noise signals on the measurement results. Depending on the measurement object, different organic / inorganic nanocomposite films can be deposited on the surface of the cantilever ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com