Thixotropic epoxy resin, preparation method and application thereof in LED chip packaging

An epoxy resin and thixotropic technology, applied in the direction of epoxy resin glue, adhesive type, electrical components, etc., can solve the problems of unsuitable chips and LED displays, high residual stress, long process route, etc., to avoid Glue mixing and dispensing process, process parameters are easy to control, and the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

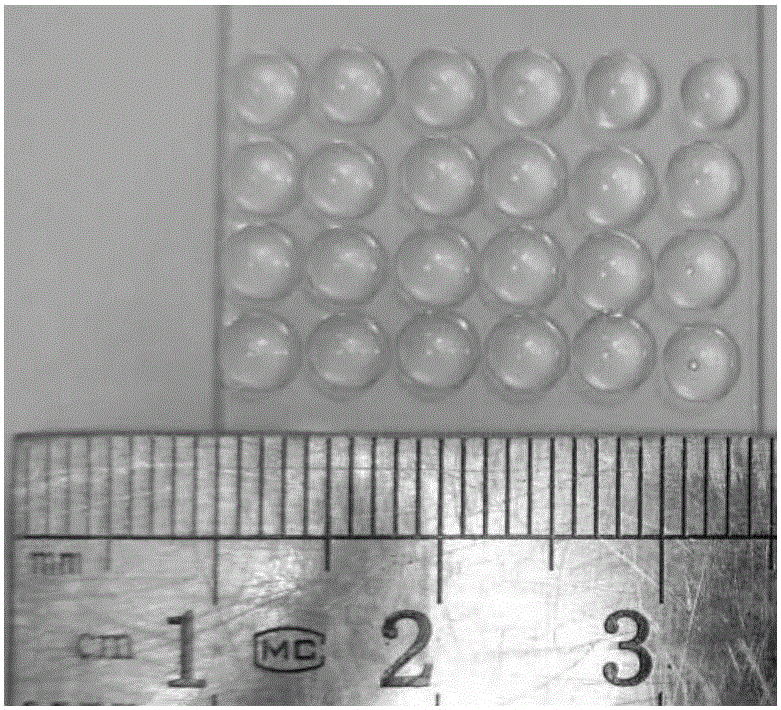

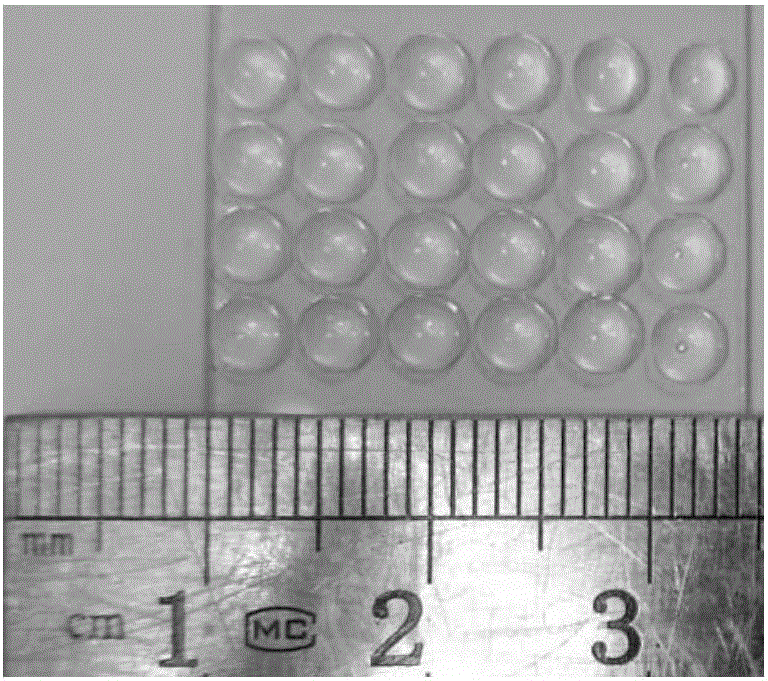

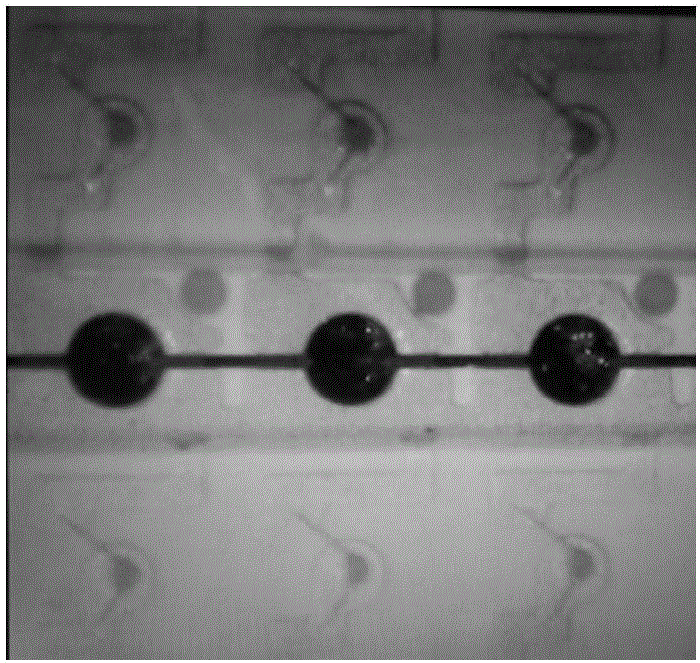

Image

Examples

Embodiment 2

[0043] The mixing temperature of embodiment 2 is the same as embodiment 1.

[0044] The components of Example 3 were uniformly mixed at a temperature of 35° C. to obtain Mixture 1 of Example 3.

Embodiment 4

[0045] The mixing temperature of embodiment 4 is with embodiment 3.

[0046] The components of Example 5 were uniformly mixed at a temperature of 50° C. to obtain Mixture 1 of Example 5.

[0047] The mixing temperature of embodiment 6, 7 or 8 is the same as embodiment 5.

[0048] Experiments have shown that 0.05 parts by weight of 2,4,6 tris[2-(3,4-epoxycyclohexylethyl)]tetramethylcyclotetrasiloxane, bis[2-(3,4 -Epoxycyclohexylethyl)]tetramethylcyclotetrasiloxane, 2,4,6,8-Tetramethyl-[2-(3,4-epoxycyclohexylethyl)]cyclotetrasiloxane alkane, 2,4,6,8-tetramethyl-2,4,6,8-tetra[3-(oxiranylmethoxy)propyl]cyclotetrasiloxane, 2,4,6 , 8-tetramethyl-2-[3-(oxiranylmethoxy)propyl]cyclotetrasiloxane instead of 0.05 parts of γ-methacryloxypropyl trimethoxy in Example 1 base silane, the others are the same as in Example 1, at a temperature of 25°C, mix uniformly, and the obtained mixture 1 can be used to prepare thixotropic epoxy resin.

[0049] Experiments have proved that 0.01 parts of...

Embodiment 10

[0053] The temperature of reaction and the reaction time of embodiment 10 are the same as embodiment 9.

[0054] The components of Example 11 were reacted for 2 hours at a temperature of 100° C. to obtain the mixture 2 of Example 11;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thixotropic index | aaaaa | aaaaa |

| thixotropic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com