Display panel and preparation method thereof

A technology for display panels and backplanes, which is applied to electrical components, electrical solid-state devices, circuits, etc., and can solve the problems of difficult process implementation and large seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

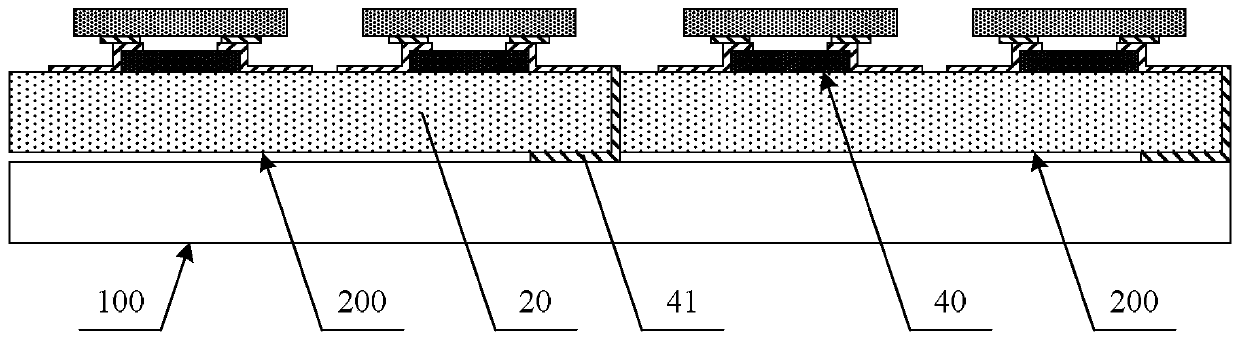

[0075] figure 2 It is a schematic structural diagram of the first embodiment of the display panel of the present invention, and the display panel is an active driving type. Such as figure 2 As shown, the main structure of the display panel in this embodiment includes a motherboard 100 and a plurality of backplanes 200 . Wherein, the motherboard 100 includes a motherboard substrate and a plurality of driving leads 11 arranged on the motherboard substrate, and each backplane 200 includes a backplane substrate and an extraction electrode 30 and a light emitting unit 40 arranged on the backplane substrate, and the light emitting unit 40 includes a driving circuit and a light-emitting diode. The light-emitting diode is a top emission structure. The light emitted by the light-emitting diode is emitted from the side of the motherboard 100, that is, the motherboard 100 serves as the display surface of the display panel.

[0076] Wherein, the plurality of backplanes 200 are arrange...

no. 2 example

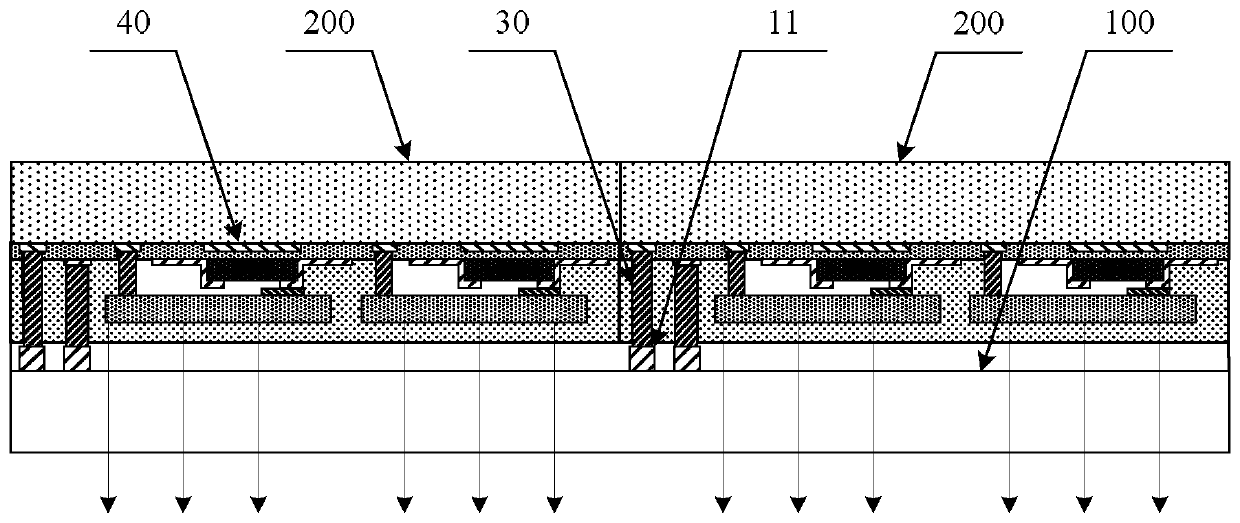

[0096] Figure 8 It is a schematic structural diagram of the second embodiment of the display panel of the present invention. The display panel is an active driving type, which is an extension based on the aforementioned first embodiment. Such as Figure 8 As shown, the main structure of the display panel of this embodiment is the same as that of the aforementioned first embodiment, including a motherboard 100 and a plurality of backplanes 200, and the plurality of backplanes 200 are set up against each other and bound to the motherboard 100 in a flip-chip manner. , the motherboard 100 includes a motherboard substrate and a plurality of drive leads 11 arranged on the motherboard substrate, each backplane 200 includes a backplane substrate and an extraction electrode 30 and a light emitting unit 40 arranged on the backplane substrate, the light emitting unit 40 Including drive circuit and light emitting diode. Different from the aforementioned first embodiment, the light-emit...

no. 3 example

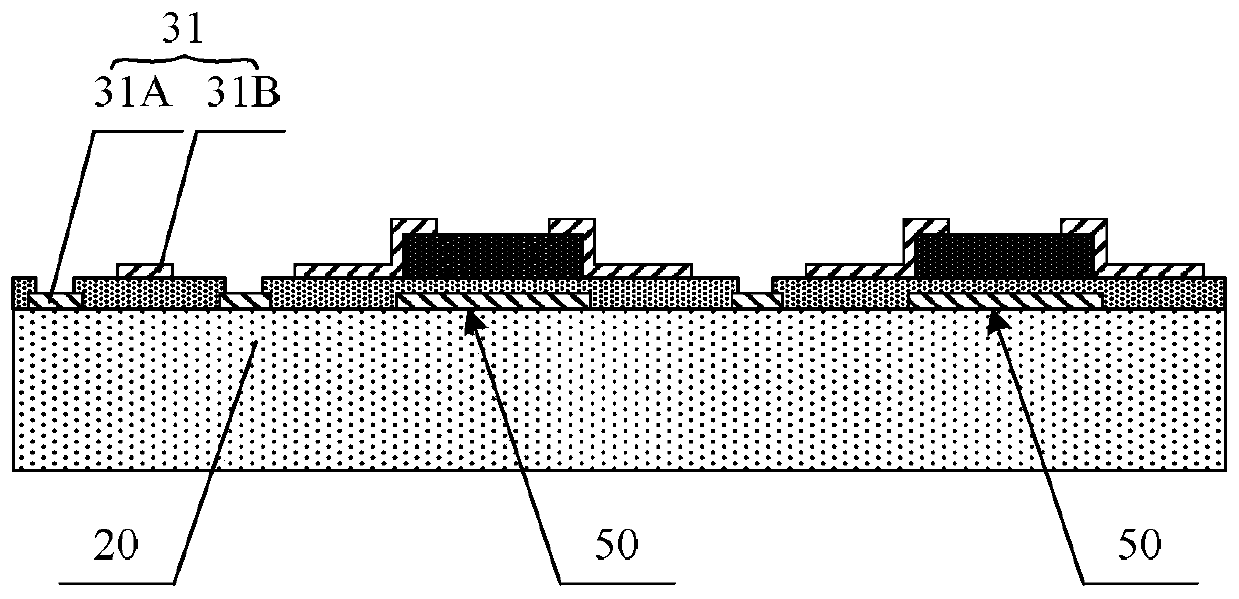

[0111] Based on the technical ideas of the foregoing embodiments, the embodiments of the present invention also provide a method for manufacturing a display panel. The preparation method of the display panel in this embodiment includes:

[0112] S1. Prepare a motherboard provided with driving leads, and prepare a plurality of backplanes provided with lead-out electrodes and light-emitting units;

[0113] S2. Bind the plurality of backplanes to the motherboard so that they are adjacent to each other, and the surface on the side of the backplane on which the lead-out electrodes and the light-emitting unit are set faces the surface on the side of the motherboard on which the driving leads are set, so The lead-out electrodes on the backboard are connected to the driving leads on the motherboard.

[0114] Wherein, preparing the motherboard provided with the driving leads in step S1 includes: forming the driving leads on the motherboard substrate; or forming a reflective layer or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com