Joint of mould plate supporting and locating device for wall building and mould plate supporting and locating device for wall building

A positioning device and formwork support technology, which is applied in the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problems affecting the anti-leakage performance of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

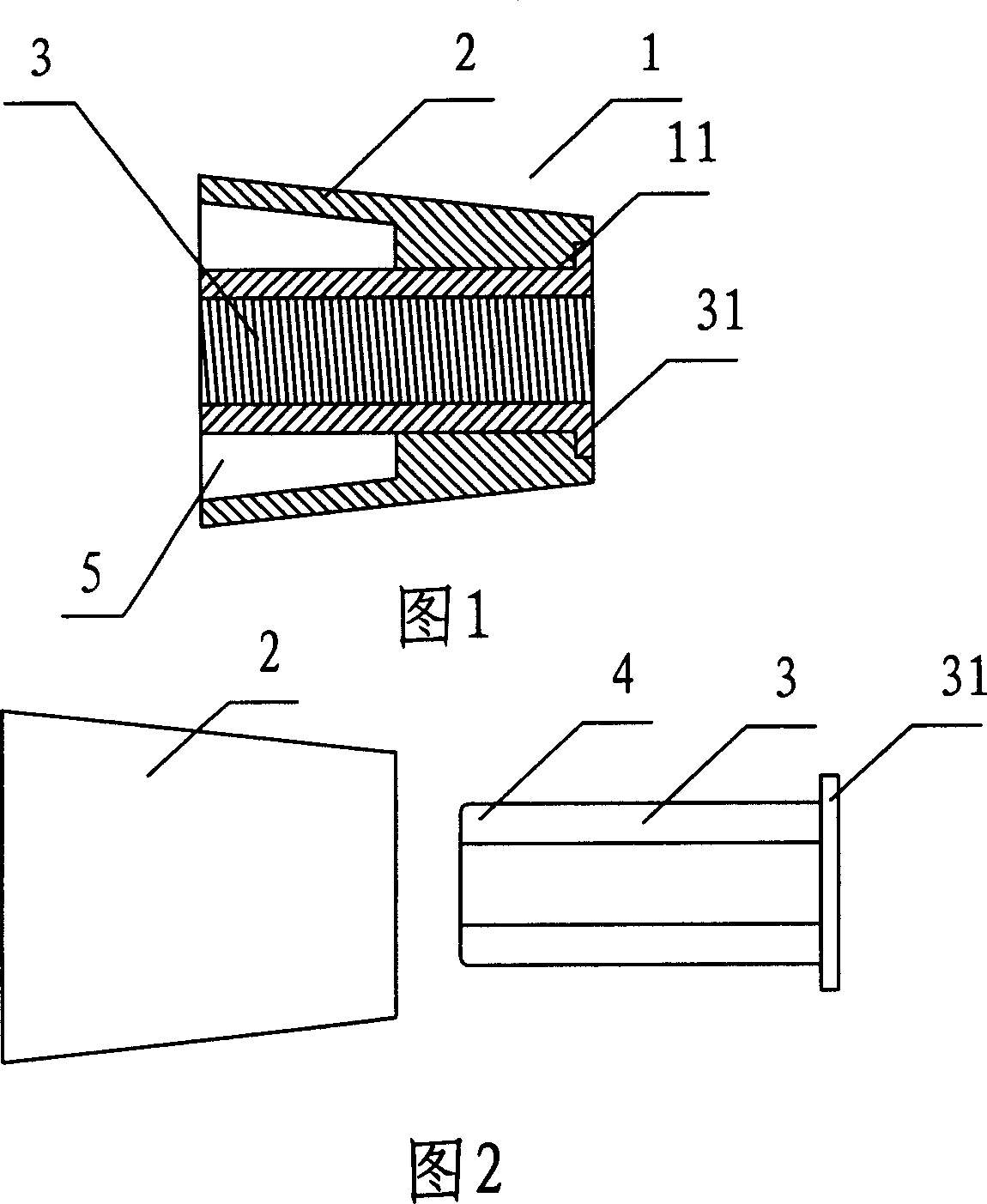

[0009] Refer to accompanying drawings 1 and 2. The joint 1 of the formwork supporting and positioning device for building walls provided by the present invention includes a tapered outer sleeve 2 and a central threaded connecting pipe 3. The head of the threaded connecting pipe has a connection shape 4 matched with the tool, and the head of the central threaded connecting pipe is connected to the Between the jackets there is a space 5 for tools to penetrate.

[0010] The central threaded connecting pipe is separated from the tapered outer casing, so that the joint can be more convenient to manufacture, and the outer casing 2 and the central threaded connecting pipe 3 are made of different materials. For example, the central threaded connecting pipe 3 is made of a metal material. The tapered housing is made of inexpensive plastic, reducing the manufacturing cost of the joint. The tapered jacket is provided with a central stepped hole 11, and the central threaded connecting pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com