Non-vacuum high-temperature solar selective absorption periodic coating and preparation method thereof

A periodic coating, medium and high temperature technology, applied in the field of coating, can solve the problems of coating corrosion resistance, too thin thickness, single function, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

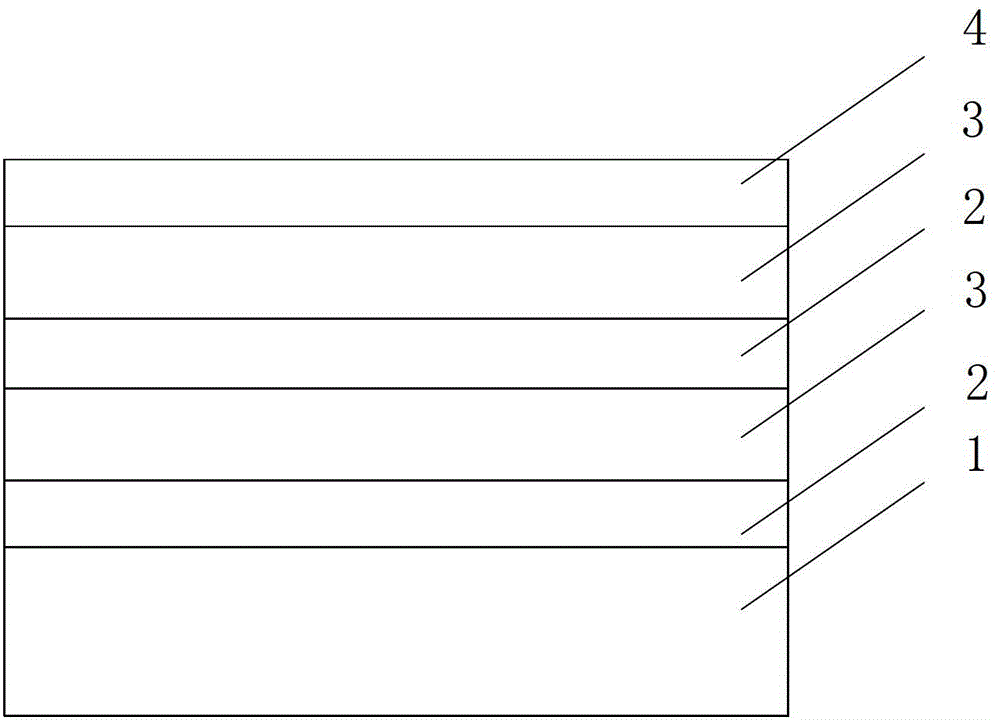

[0020] Example 1: Periodic coating for selective absorption of solar energy at high temperature in non-vacuum

[0021] 1) Put the base material 1, that is, 301 stainless steel into the multi-arc ion plating furnace, and install the Ti-Al target, where Al:Ti=3:1;

[0022] 2) Infuse nitrogen gas, control the deposition time and gas flow rate to deposit the metal nitride coating 2 containing the metal component, and obtain an AlN-TiN coating containing the metal component Ti, with a thickness of 120nm;

[0023] 3) Reduce the flow rate of nitrogen gas and feed oxygen at the same time, control the deposition time and gas flow rate to deposit the metal oxynitride coating 3 containing metal components, and obtain an AlON-TiON coating containing metal component Ti with a thickness of 150nm;

[0024] 4) Repeat step 2) and step 3) twice to obtain a periodic coating;

[0025] 5) Deposit a dense oxide film 4 according to the periodic coating, and the coating contains Ti element, then dep...

Embodiment 2

[0030] Example 2: Periodic coating for selective absorption of solar energy at high temperature in non-vacuum

[0031] 1) Put the base material 1, that is, 301 stainless steel into a multi-arc ion plating furnace, and install a Cr-Al target, where Al:Cr=2:1;

[0032] 2) Infuse nitrogen gas, control the deposition time and gas flow rate to deposit the metal nitride coating 2 containing the metal component, and obtain an AlN-CrN coating containing the metal component Cr, with a thickness of 115nm;

[0033] 3) Reduce the flow rate of nitrogen gas and feed oxygen at the same time, control the deposition time and gas flow rate to deposit the metal oxynitride coating 3 containing metal components, and obtain an AlON-CrON coating containing metal component Cr with a thickness of 130nm;

[0034] 4) Repeat step 2) and step 3) twice to obtain a periodic coating;

[0035] 5) Deposit a dense oxide film 4 according to the periodic coating, and the coating contains Cr element, then deposit...

Embodiment 3

[0039]Embodiment 3: High temperature solar energy selective absorption periodic coating in non-vacuum

[0040] 1) Put the base material 1, namely 301 stainless steel, into the magnetron sputtering furnace, and install the Ti-Al target, where Al:Ti=1:2;

[0041] 2) Infuse nitrogen gas, control the deposition time and gas flow rate to deposit the metal nitride coating 2 containing the metal component, and obtain an AlN-TiN coating containing the metal component Ti, with a thickness of 200nm;

[0042] 3) Reduce the flow rate of nitrogen gas and feed oxygen at the same time, control the deposition time and gas flow rate to deposit the metal oxynitride coating 3 containing metal components, and obtain an AlON-TiON coating containing metal component Ti with a thickness of 180nm;

[0043] 4) Repeat step 2) and step 3) twice to obtain a periodic coating;

[0044] 5) Deposit a dense oxide film 4 according to the periodic coating, and the coating contains Ti element, then deposit TiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com