Preparation method of meso-porous silica nanoparticles

A technology of mesoporous silica and nanoparticles, applied in the field of biomedicine, to achieve good biocompatibility and biodegradability, simple synthesis process, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

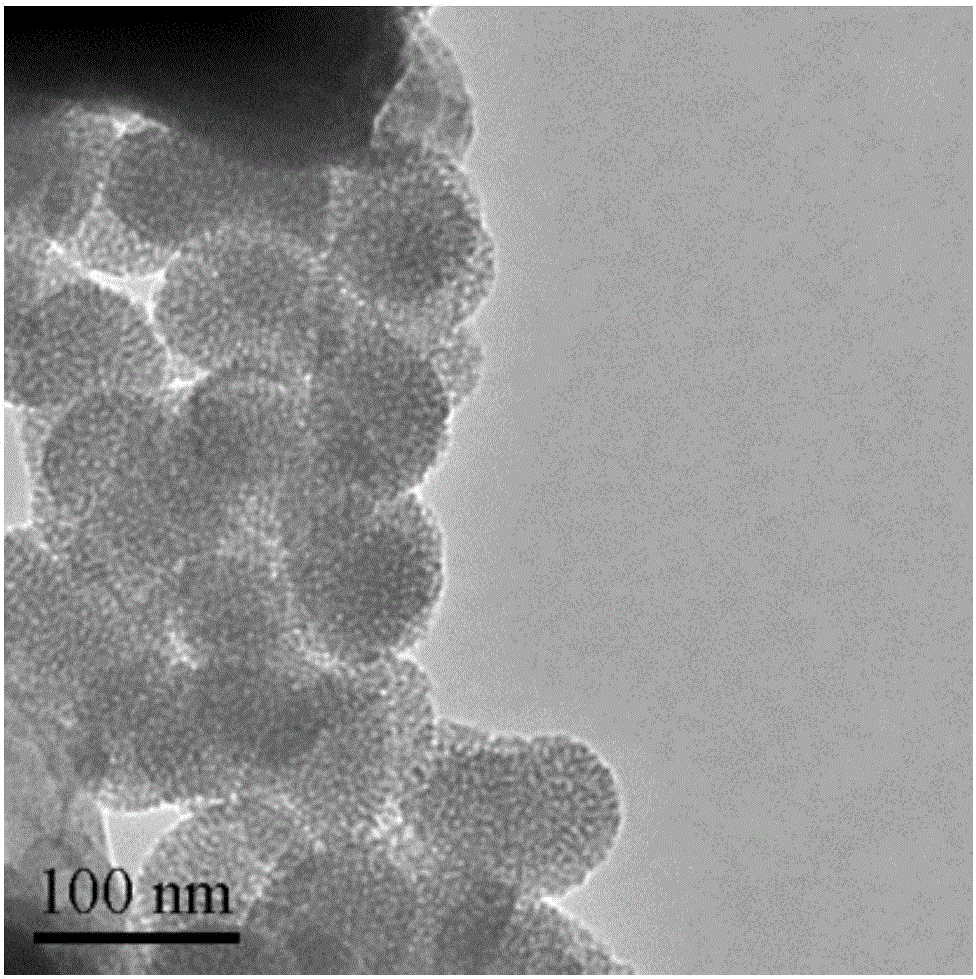

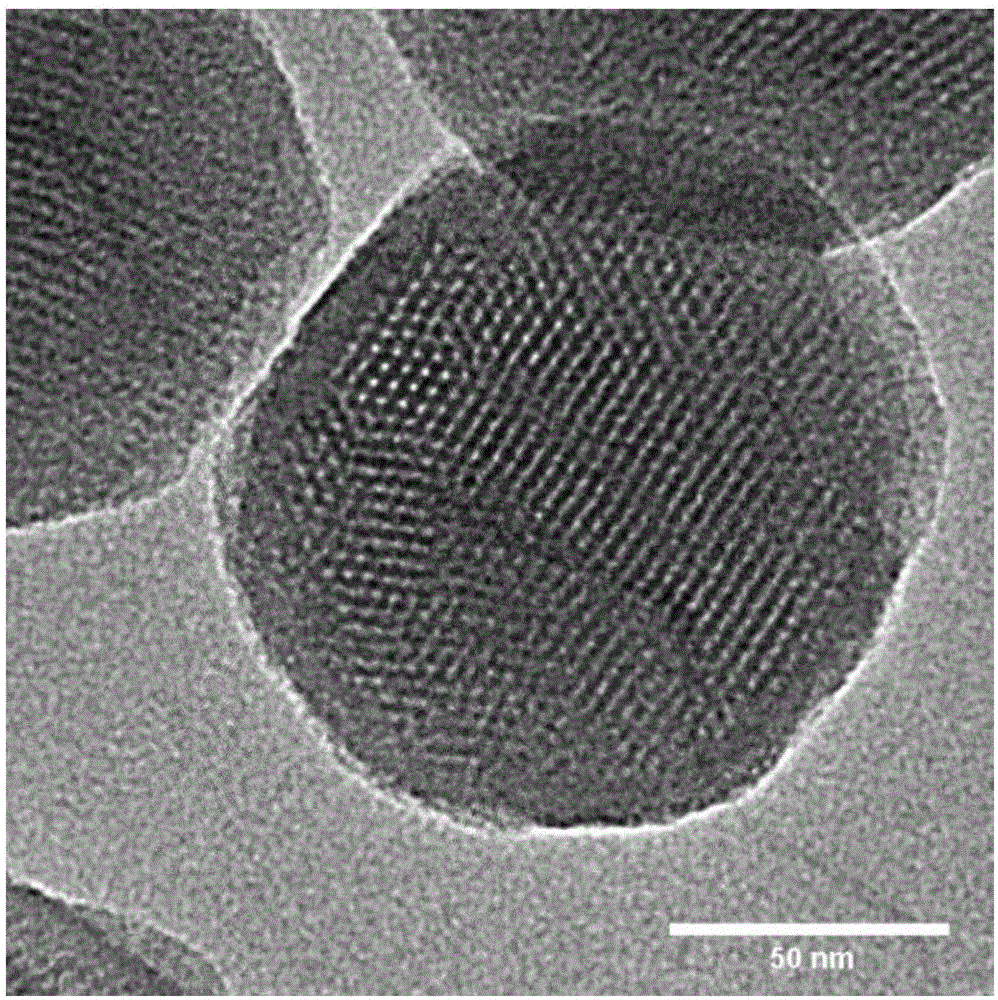

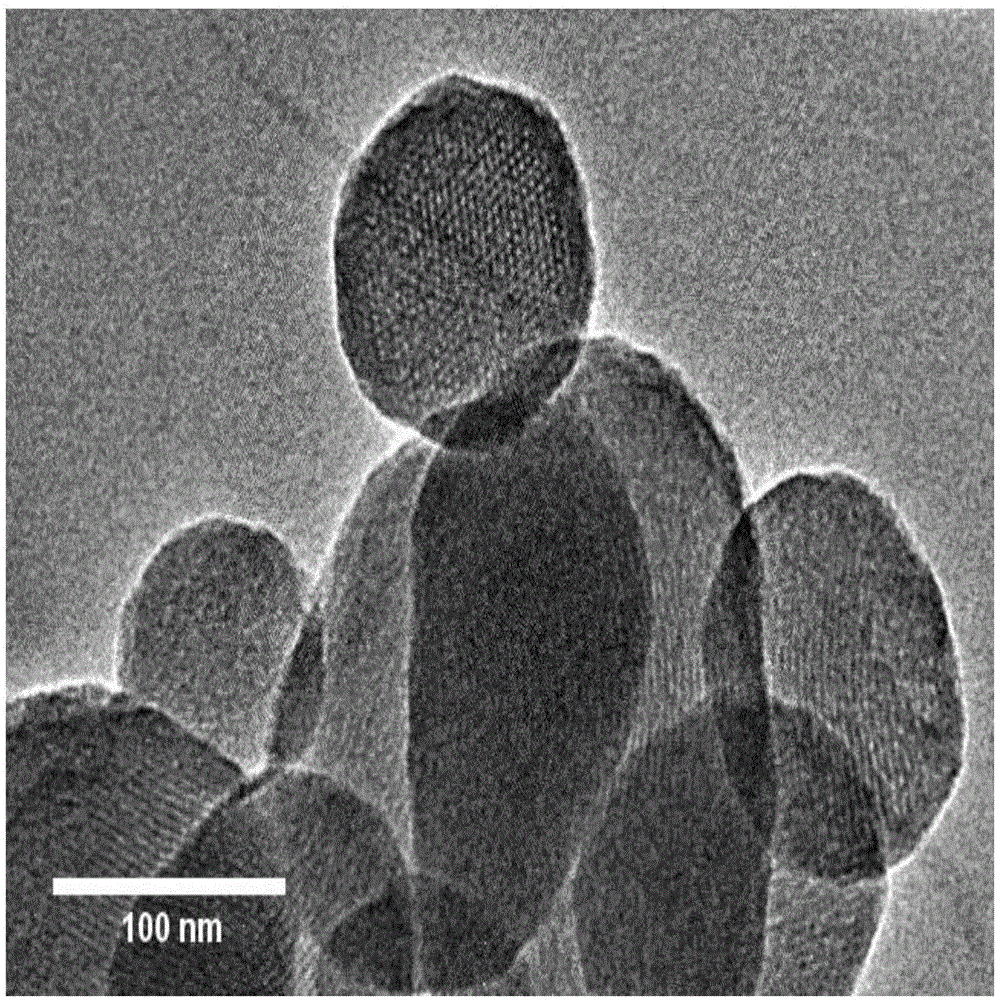

Image

Examples

Embodiment 1

[0031] (1) Pour 16mL of distilled water and 2.35mL of ethanol into a 100mL sealed round bottom flask with a stopper, then add 0.56g of cetyltrimethylammonium chloride (CTAC), and stir magnetically at room temperature for 10min to make the solution fully mix;

[0032] (2) Then add 2.6mL triethanolamine to the mixed solution prepared in step (1), and continue to stir for 15min until the triethanolamine is completely dissolved;

[0033] (3) Heat the above solution to 60°C, then add 1.454mL orthosilicate ethyl ester within 2-3min, and continue to stir for 2h;

[0034] (4) After the reaction solution is cooled to room temperature, the product obtained is centrifuged, and the obtained solid is washed several times with distilled water and ethanol;

[0035] (5) Removal of the template: the solid obtained in step (4) was placed in a mixed solution consisting of 45 mL of ethanol and 5 mL of hydrochloric acid (37%, volume fraction), and refluxed twice at 60° C. for 2 hours each time. ...

Embodiment 2

[0039] The preparation method for preparing mesoporous silica nanoparticles is the same as in Example 1, except that the amount of TEA added is 0.87 mL, and the molar ratio of TEOS / TEA is controlled to be 1:1.

[0040] The same method as in Example 1 was used to test the particle size of the mesoporous silica nanoparticles prepared in this example. Tested by the particle size analyzer, the average particle size of the obtained mesoporous silica nanoparticles is 200.6nm, the particle size is normally distributed, and the particle size dispersion index is 0.199. The particle size of the mesoporous silica nanoparticles synthesized under this condition is It is a bit too large, which may be caused by the agglomeration of nanoparticles.

Embodiment 3

[0042] The preparation method for preparing mesoporous silica nanoparticles is the same as that of Example 1, except that the amount of TEA added is 1.74 mL, and the molar ratio of TEOS / TEA is controlled to be 1:2.

[0043] The same method as in Example 1 was used to test the particle size of the mesoporous silica nanoparticles prepared in this example. As tested by a particle size analyzer, the average particle size of the obtained mesoporous silica nanoparticles was 150.8nm, the particle size was normally distributed, and the particle size dispersion index was 0.108.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com