Trench type semiconductor power device

一种半导体、器件的技术,应用在低功耗半导体功率器件领域,能够解决工艺成本高、增加工艺复杂度、工艺难度大等问题,达到避免复杂工艺、增加漂移区浓度、大灵活性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

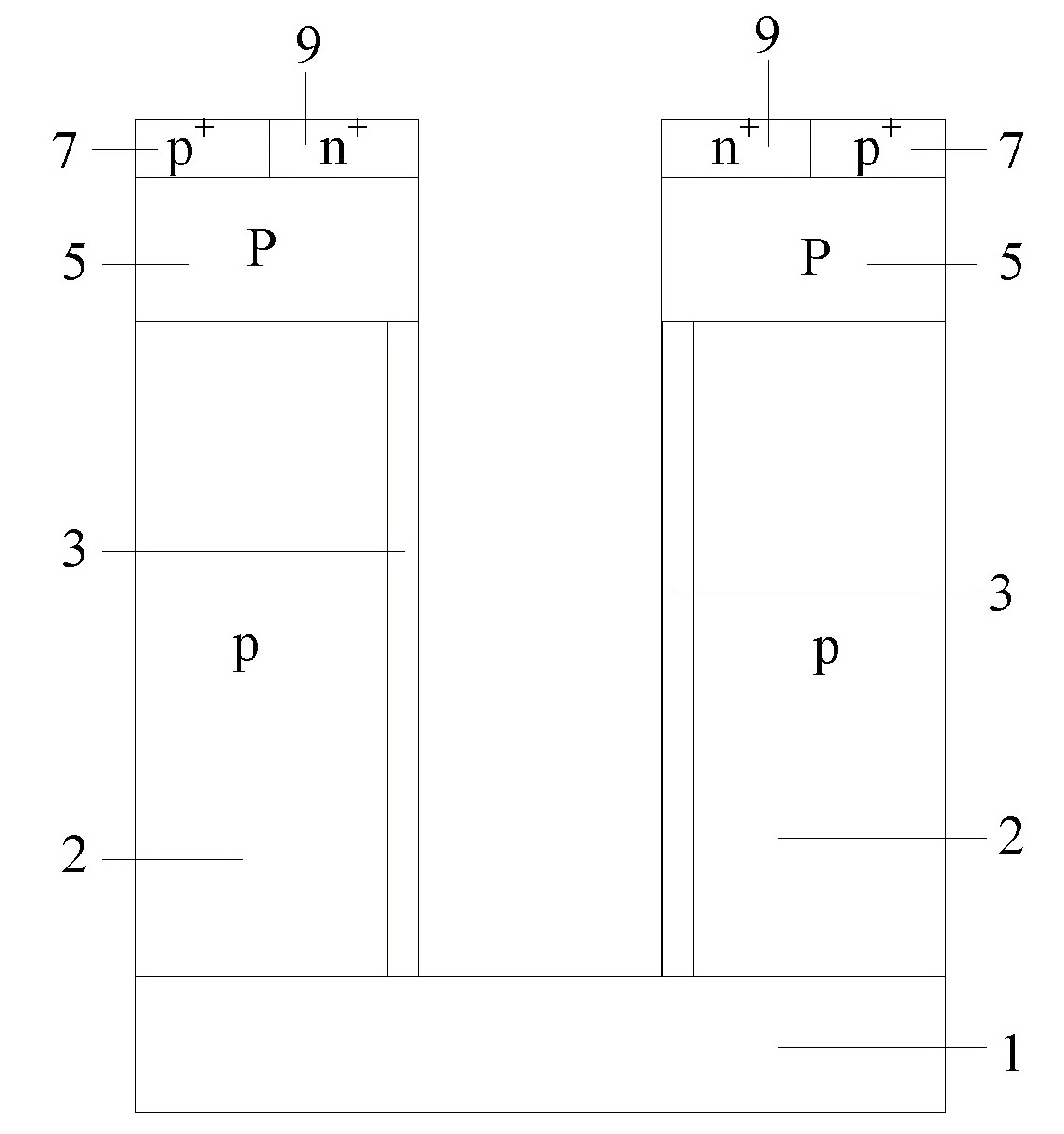

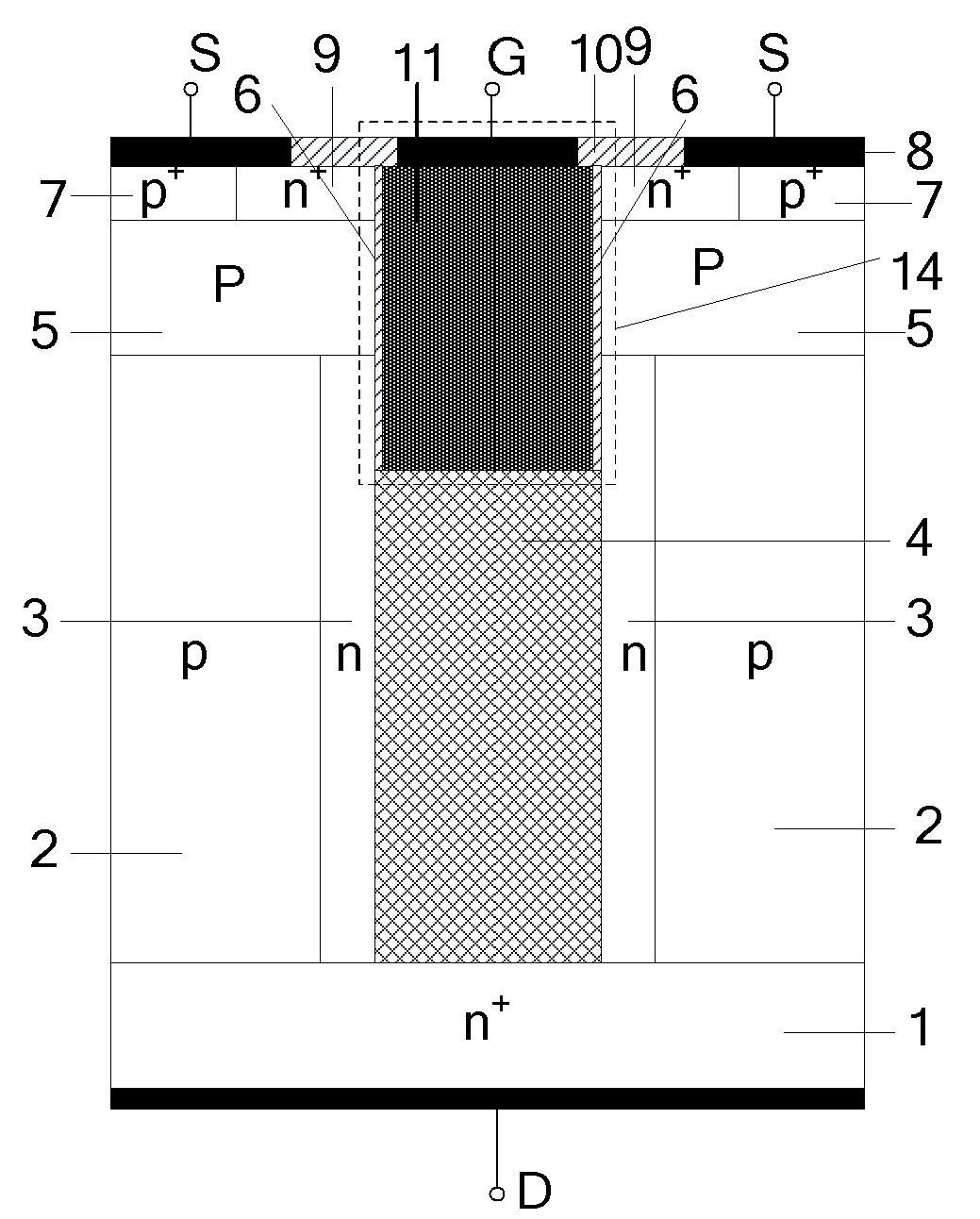

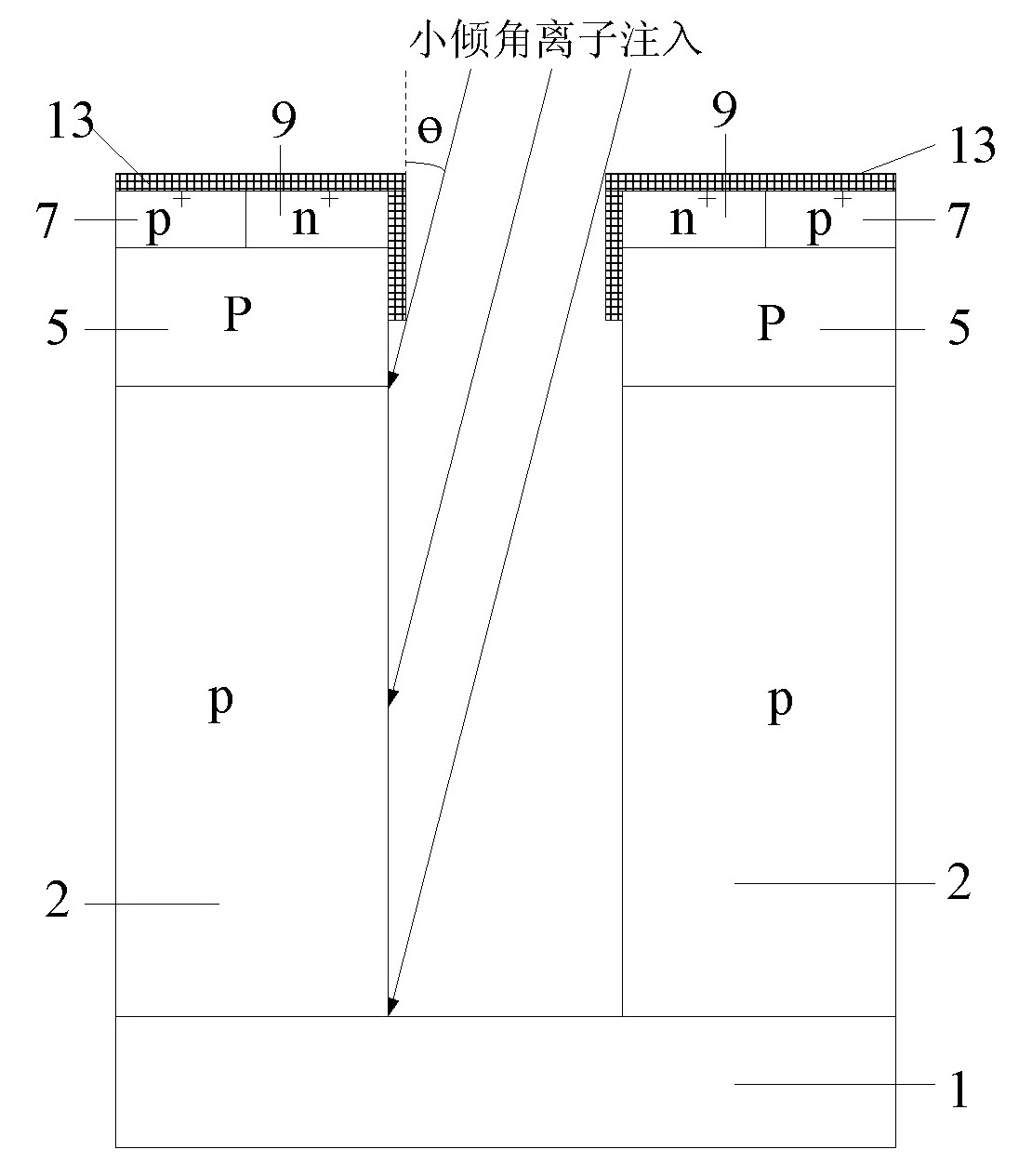

[0042] Conventional trench-gate VDMOS structure with superjunction, such as figure 1 As shown, on the semiconductor substrate 1 is a drift region, the drift region includes alternating p-type semiconductor regions 2' and n-type semiconductor regions 3', the p-type semiconductor regions 2' and n-type semiconductor regions 3' are columnar, and also Referred to as a p-column region and an n-column region, the p-type semiconductor region 2' and the n-type semiconductor region 3' form a super junction structure. The n-type semiconductor region 3' is located directly below the groove gate structure 14, and the width of the n-type semiconductor region 3' is greater than the width of the groove gate structure. The groove gate structure includes a gate dielectric 6 and a conductive material 11 surrounded by the gate dielectric. From the surface of the conductive material 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com