Composite foam flooding method suitable for oil field exploitation

A composite flooding and composite flooding technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of increasing the difficulty of injection technology and treatment of produced fluid, and cannot reduce oil-water interfacial tension and reduce polymer viscoelasticity, etc. problem, to achieve the effect of flexible injection mode, good oil displacement effect and ultra-low interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

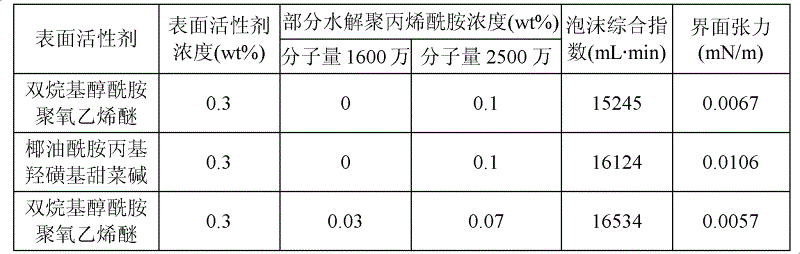

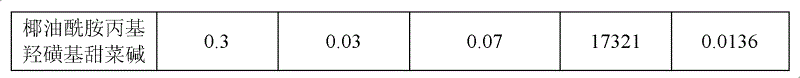

[0048] In this embodiment, the foamability and foam stability of the foaming agent are tested by using a foam scanner. The test method is as follows: at 45° C., inject carbon dioxide into the foam scanner at a flow rate of 30 mL / min for 5 minutes.

[0049] The volume of the foam produced at the end of the gas injection was used as the foamability evaluation index, that is, the foam volume (V). The time when the foam decays by half is used as the foam stability evaluation index, that is, the foam half-life (t). Foam Composite Index (FCI) can consider both foam volume and foam half-life, FCI=3Vt / 4. A TX500C spinning drop interfacial tensiometer was used at 45°C and 5000 rpm. Measure the interfacial tension of oil and water for 2 hours under the rotating speed of 3 , the freezing point is 31°C, the acid value is 0.09mgKOH / g, the wax content is 27.85%, and the sulfur content is 0.13%). The foam comprehensive index and interfacial tension of different foaming agents are shown in...

Embodiment 2

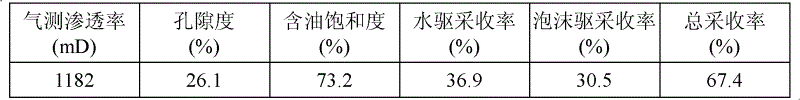

[0055] This example provides a foam composite flooding method. The man-made three-layer heterogeneous positive rhythm core (size 4.5cm×4.5cm×30cm) is selected to simulate the formation, and the coefficient of variation of the permeability is 0.72. Firstly, the core was evacuated to -1MPa at 45°C for two hours, saturated with simulated brine, and the measured pore volume was 157mL.

[0056] For the simulated oil (viscosity of 9.5cp) saturated with water in the core saturated Daqing Oilfield, the oil saturation is determined to be 73.2%, aged for more than 12 hours.

[0057] Carry out water flooding on the core saturated with simulated oil until the water content of the produced fluid is 98%, and after calculating the water flooding recovery, follow the following four steps to carry out foam composite oil flooding: pre-polymer slug, pre-adsorption auxiliary slug 1. Foam flooding main slug and polymer protection slug, after completing four steps, follow-up water flooding until th...

Embodiment 3

[0068] This embodiment provides a foam composite flooding method, wherein the specific operations and parameters of the four steps of foam composite flooding are as follows:

[0069] (1) Inject the pretreatment pre-polymer slug: the polymer is partially hydrolyzed polyacrylamide, its molecular weight is 25 million, the degree of hydrolysis is 23%, and the concentration is 0.15wt%; the inorganic salt is sodium chloride, and the concentration is 0.24 wt%; the viscosity of the pretreatment polymer slug is 74mPa·s, and the injection volume is 10% of the core pore volume.

[0070](2) Inject the auxiliary slug of foam composite flooding as a pre-adsorption slug: the surfactant is dialkyl alcohol amide polyoxyethylene ether (containing 4-6 polyoxyethylene groups, 16-18 alkyl carbons), the concentration is 0.3wt%; the foam stabilizer is partially hydrolyzed polyacrylamide, its molecular weight is 12 million, the degree of hydrolysis is 23%, and the concentration is 0.1wt%; the inorgan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com