Low-temperature solution preparation method of high-dielectric zirconium oxide thin film

A low-temperature solution and zirconia technology, which is applied in the field of low-temperature solution preparation of high-dielectric zirconia films, can solve the problems of increasing equipment complexity, cost, and improvement, and achieves low cost, cheap and easy-to-obtain raw materials, and high dielectric properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

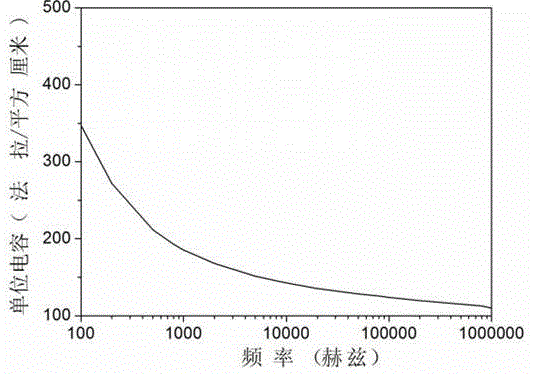

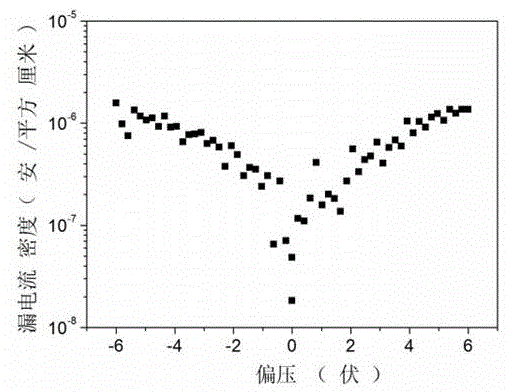

Embodiment 1

[0021] Weigh 0.023 g of zirconium chloride, measure 10 ml of ethanol solution, prepare a zirconia precursor solution with a concentration of 0.01 mol / L, and form a clear and transparent zirconia precursor solution after 3 hours of magnetic stirring and ultrasonic dispersion. Apply the zirconia precursor solution to the cleaned substrate to form a zirconia precursor film, perform a preheating treatment at 50°C, and then undergo light wave annealing at 500W, 20 minutes, and 250°C to obtain a zirconia dielectric film .

Embodiment 2

[0023] Weigh 1.775 g of zirconium sulfate, measure 10 ml of ethylene glycol methyl ether solution, configure a zirconia precursor solution with a concentration of 0.5 mol / L, and form a clear and transparent zirconia precursor solution after 0.1 hour of magnetic stirring and ultrasonic dispersion . Apply the zirconia precursor solution to the cleaned substrate to form a zirconia precursor film, perform a preheating treatment at 150 °C, and then undergo light wave annealing at 100W, 120 minutes, and 150 °C to obtain a zirconia dielectric film .

Embodiment 3

[0025] Weigh 0.215 g of zirconium nitrate, measure 5 ml of aqueous solution, prepare a zirconia precursor solution with a concentration of 0.1 mol / L, and form a clear and transparent zirconia precursor solution after 1 hour of magnetic stirring and ultrasonic dispersion. Apply the zirconia precursor solution to the cleaned substrate to form a zirconia precursor film, perform a preheating treatment at 90°C, and then undergo light wave annealing at 700W, 30 minutes, and 280°C to obtain a zirconia dielectric film .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com