Aluminum alloy with micro-arc oxide ceramic membrane on surface and preparation method thereof

A micro-arc oxidation, aluminum alloy technology, applied in the direction of anodizing, surface reaction electrolytic coating, electrolytic coating, etc. The application of the loose layer on the membrane surface is hindered, so as to reduce the production cost and improve the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

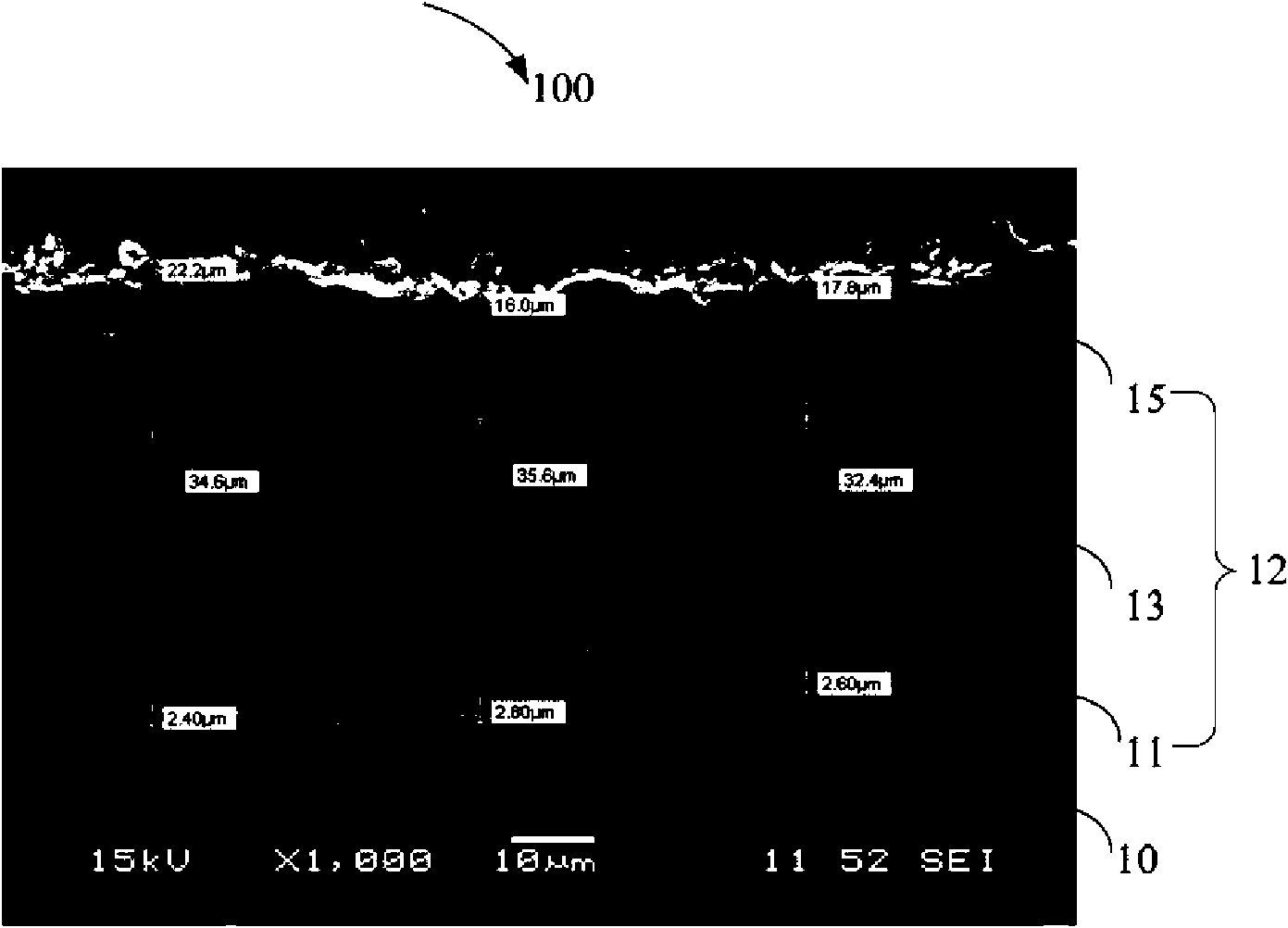

[0018] The preparation method of the aluminum alloy 100 with the micro-arc oxidation ceramic film 12 on the surface of the preferred embodiment of the present invention comprises the following steps:

[0019] First, put the aluminum alloy substrate 10 into an alkaline decontamination solution for decontamination treatment for about 10 minutes, so as to remove oil stains and dirt on the substrate 10 . After decontamination, the substrate 10 is washed with water.

[0020] The decontaminated aluminum alloy substrate 10 is placed in a stainless steel oxidation tank containing an electrolyte. When a forward voltage is applied, the aluminum alloy substrate 10 is used as an anode, and the stainless steel oxidation tank is used as a cathode. The electrolyte solution can be one or more of phosphate solution, borate solution, silicate solution, aluminate solution or hydroxide solution. Described phosphate solution can be sodium hexametaphosphate ((NaPO 3 ) 6 , 5.0~25.0g / L), sodium tr...

Embodiment 1

[0026] Embodiment 1: choose 1060 type aluminum alloy matrix, with potassium hydroxide (KOH, 1.0g / L), sodium silicate (Na 2 SiO 3 , 2.0g / L) of the mixed solution is the electrolyte, using a constant current, with the substrate as the anode, and the stainless steel oxidation tank as the cathode for the initial oxidation of the substrate. The constant current density is 5A / dm 2 , the initial oxidation treatment time was 1 minute, and the treatment temperature was 20°C. After the initial oxidation is completed, positive and negative bidirectional pulse voltages are used to continue to oxidize the substrate, and the positive and negative voltages rise to a maximum value at a certain rate during switching and then remain constant. Among them, the maximum positive voltage is set to 500V, the maximum negative voltage is set to 60V, the positive and negative pulse widths are both 1000μs, and the pulse interval is 300μs. The total time of the continuous oxidation treatment is 60 minu...

Embodiment 2

[0027] Embodiment 2: choose 2017 type aluminum alloy matrix, with sodium hydroxide (NaOH, 2.0g / L), sodium fluoride (NaF, 20.0g / L), sodium metaaluminate (NaAlO 2 , 2.0g / L) mixed solution as the electrolyte, using a constant current, with the substrate as the anode and the stainless steel oxidation tank as the cathode to perform initial oxidation on the substrate. The constant current density is 6A / dm 2, the initial treatment time was 2 minutes, and the treatment temperature was 20 °C. After the initial oxidation is completed, the positive and negative bidirectional pulse voltages are used to continue the oxidation treatment of the substrate. The positive and negative voltages rise to a maximum value at a certain rate during switching and remain constant. The maximum positive voltage is set to 550V, and the maximum negative voltage is set to 550V. It is 90V, the positive and negative pulse width is 2000μs, and the pulse interval is 500μs. The total time of the continuous oxida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com