Flexible light emitting diode package structure and manufacturing method thereof

A technology of light-emitting diodes and packaging structures, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of export, poor heat dissipation efficiency, and difficult heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

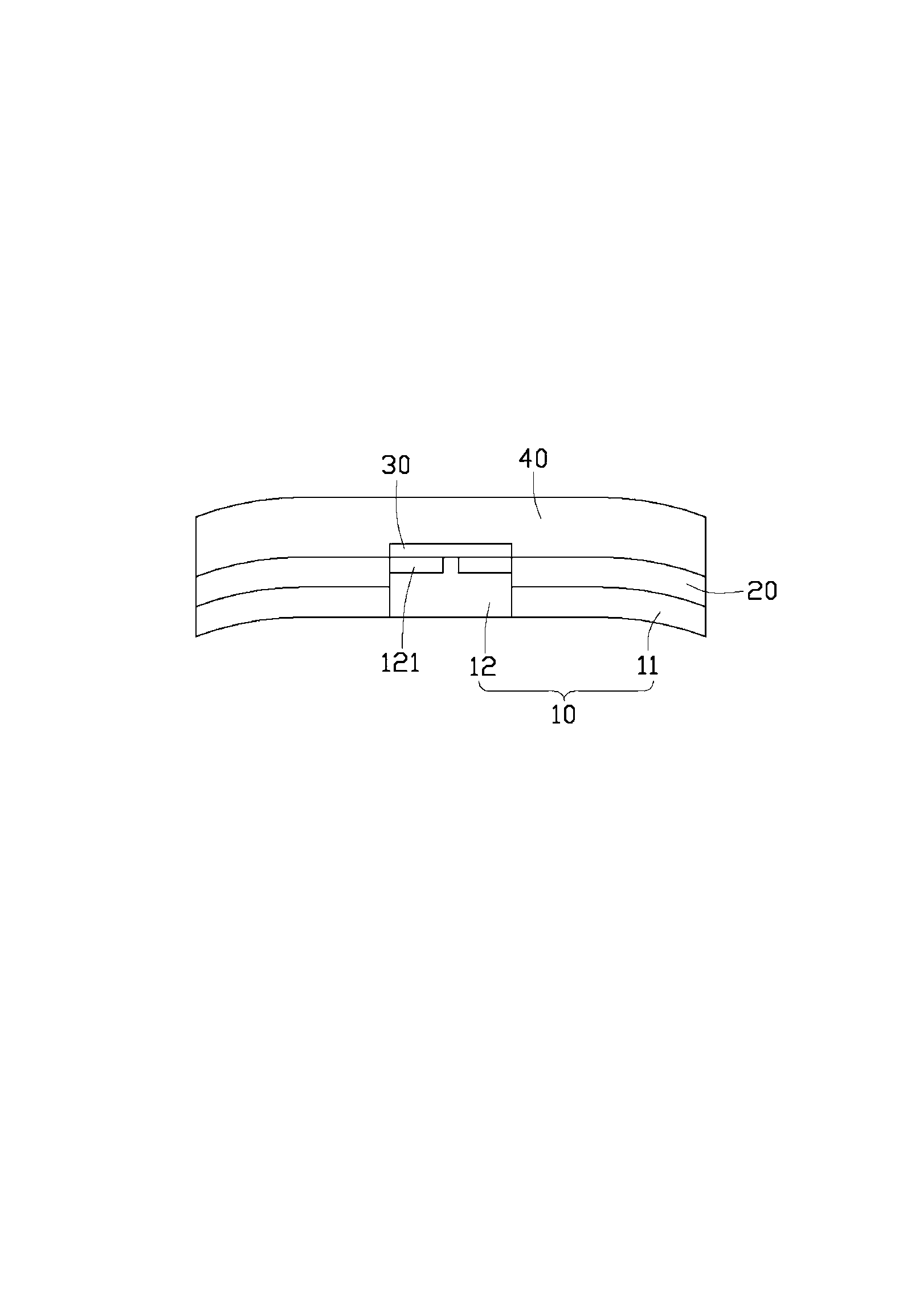

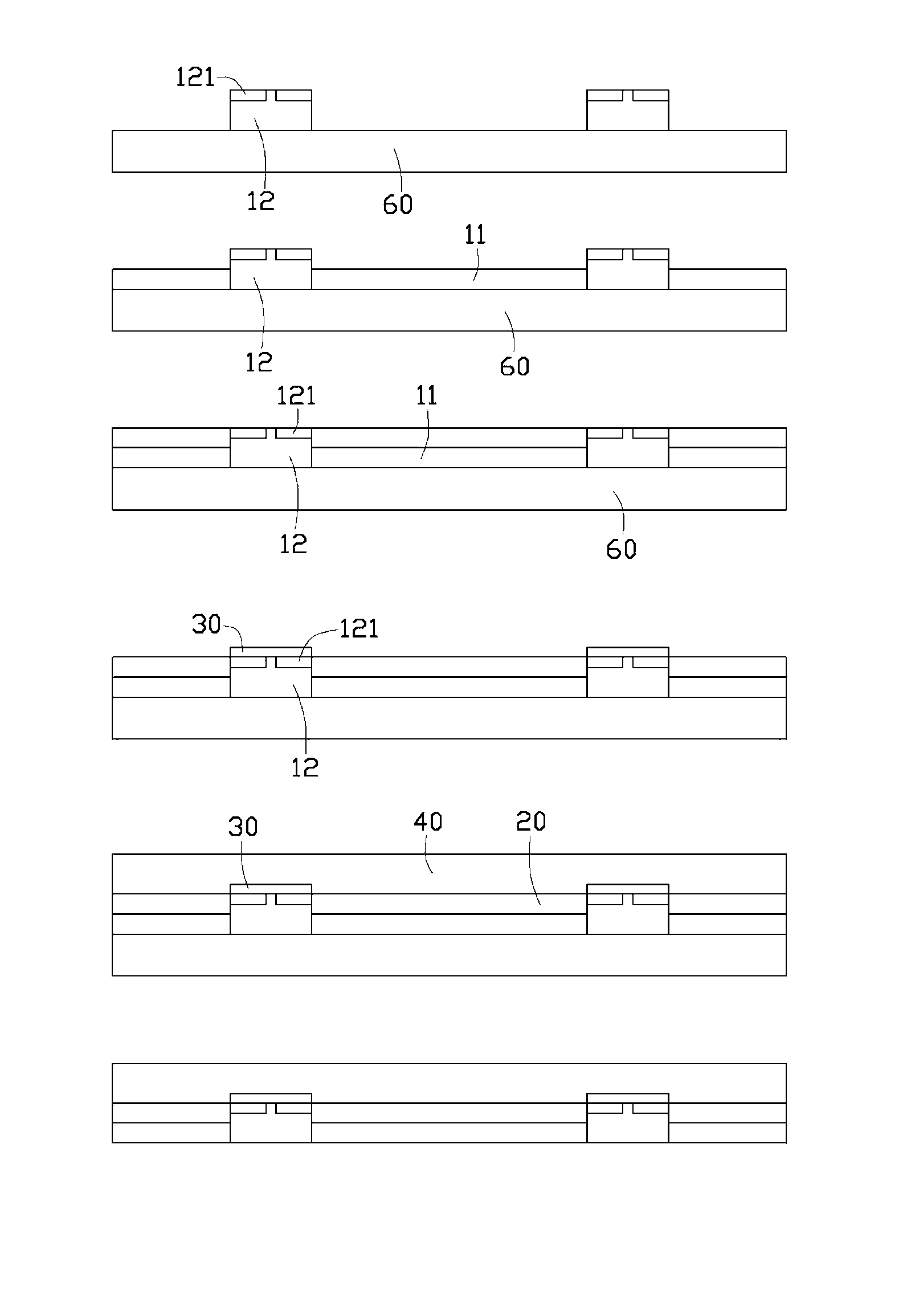

[0021] see figure 1 A flexible LED packaging structure provided in the first embodiment of the present invention includes a flexible substrate 10, two conductive electrodes 20 disposed on the flexible substrate 10, The LED chip 30 and the transparent covering layer 40 covering the LED chip 30 .

[0022] The flexible substrate 10 is a flat plate structure, which includes a flexible substrate 11 and a rigid substrate 12 thicker than the flexible substrate 11 . The rigid substrate 12 includes a top surface, a bottom surface opposite to the top surface, and a side surface connecting the top surface and the bottom surface. The flexible substrate 11 is surrounded and connected to the side surface of the rigid substrate 12, and the rigid substrate 12 The bottom surface is flush with the bottom surface of the flexible substrate 11 . The flexible substrate 11 is made of insulating material, and in this embodiment, the flexible substrate 11 is made of silicone resin or epoxy resin mat...

Embodiment approach 2

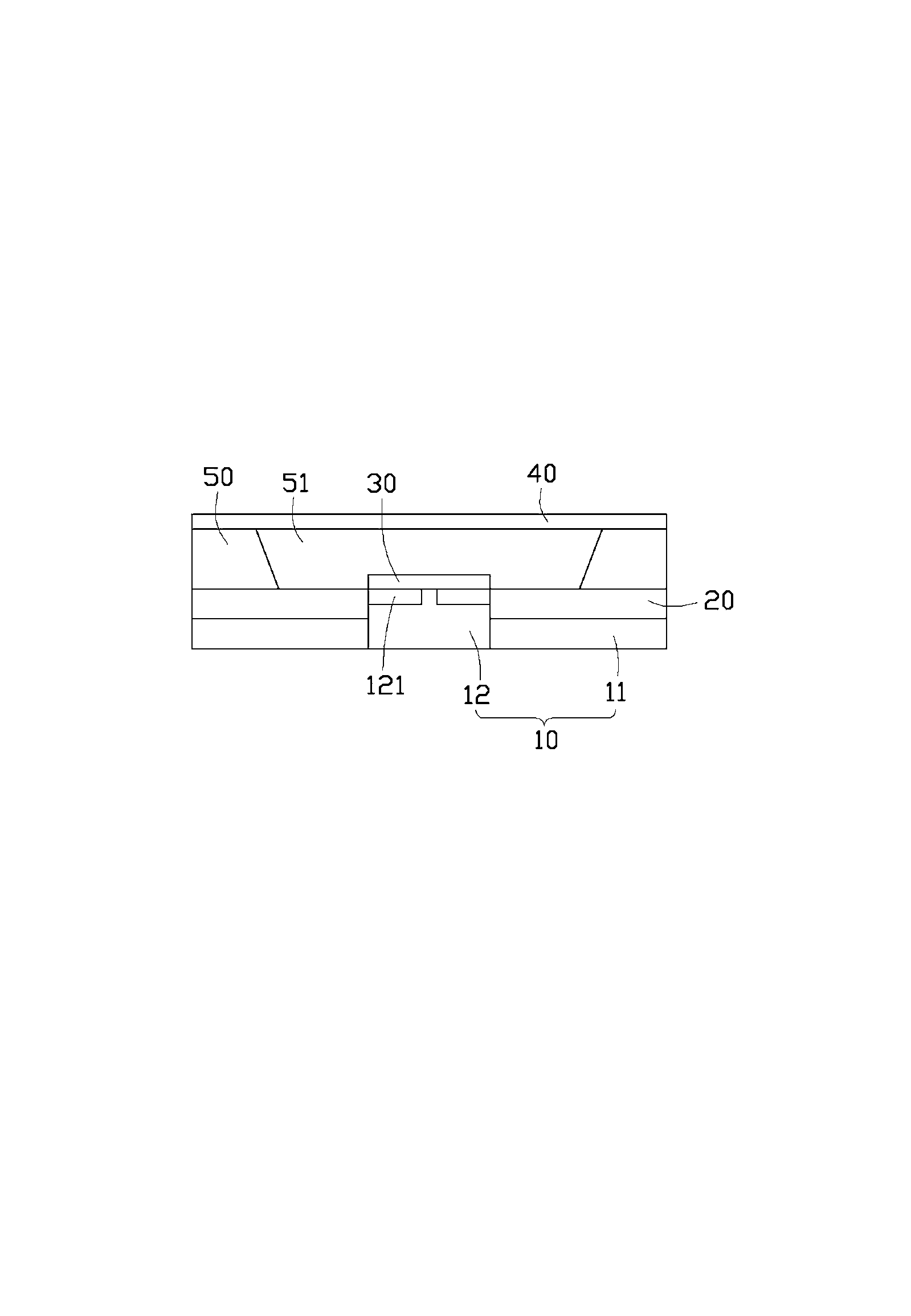

[0029] see figure 2 , which is a schematic diagram of the flexible light emitting diode packaging structure provided in the second embodiment of the present invention. The difference between the flexible light emitting diode packaging structure in the second embodiment and the flexible light emitting diode packaging structure in the first embodiment is that : The flexible light emitting diode packaging structure of the second embodiment also includes a reflective cup structure 50 arranged on the flexible substrate 10, the reflective cup structure 50 is opened from the top surface along the bottom surface to form a housing cup 51, The inner surface of the accommodating cup 51 is an inclined surface, which extends from the top surface of the reflecting cup structure 50 to the bottom surface and inclines inwardly along the radial direction of the accommodating cup 51, so that the entire accommodating cup 51 is wide at the top and narrow at the bottom. Was a funnel shape. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com