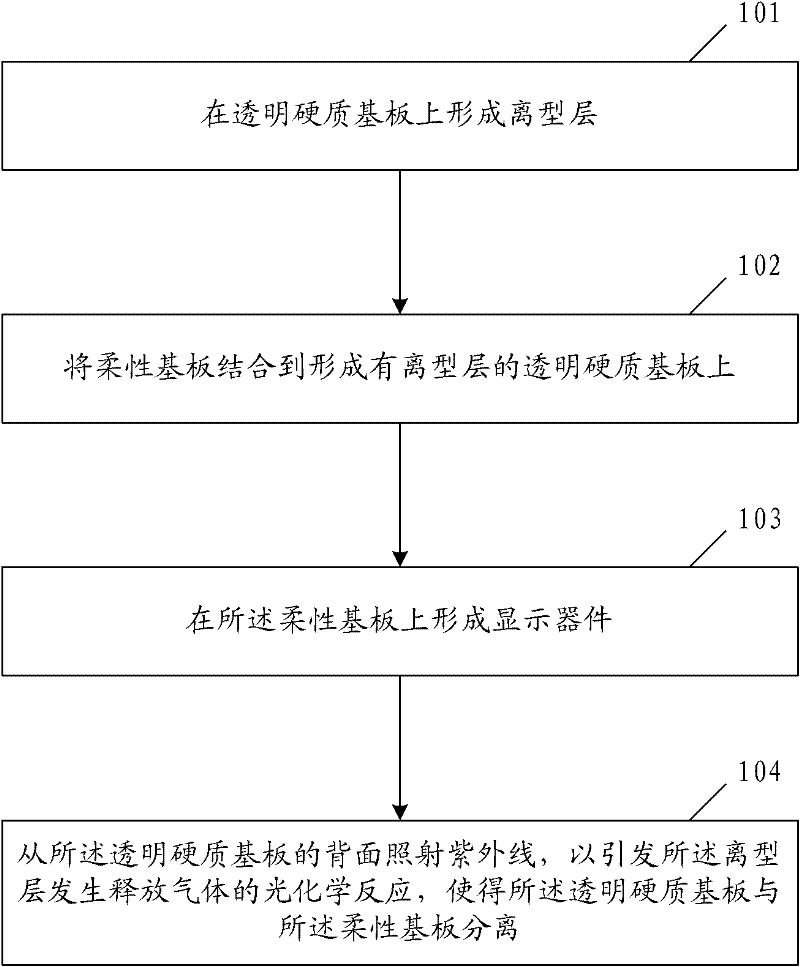

Manufacturing method of flexible display devices

A technology for flexible display devices and flexible substrates, applied in identification devices, nonlinear optics, organic semiconductor devices, etc., can solve problems such as low production efficiency, decreased adhesion performance, and poor peeling uniformity, so as to reduce production costs and simplify production The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

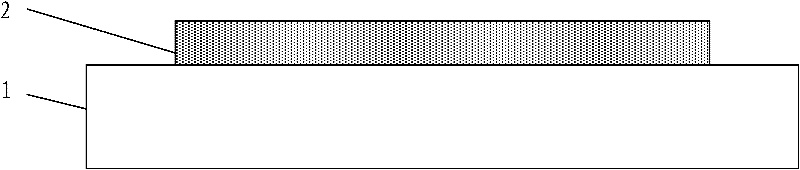

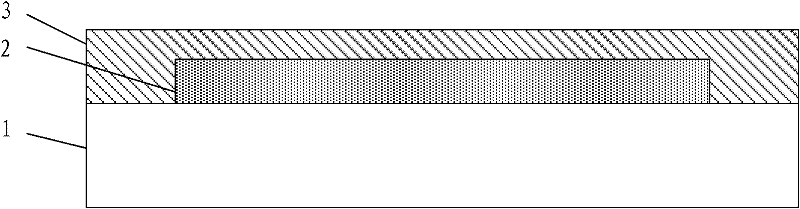

[0042] The ultraviolet light decomposition material is a material that undergoes a photochemical reaction when exposed to ultraviolet light, and the reaction product contains gas components. The embodiment of the present invention provides a method for preparing a flexible display device. A release layer is prepared by adding a large amount of inert substances (substances that do not react with it) to the ultraviolet light decomposition material, which is matched with a flexible substrate and removed by pasting. The flexible display device can be prepared in this way, so that the flexible display product can be prepared at a low temperature using a production method very close to the traditional TFT-LCD array substrate, so as to reduce the production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com