Flexible sensor and preparation method thereof

A flexible sensor and sensing layer technology, applied in the field of strain sensors, can solve the problems of low sensitivity, poor biological tolerance, inability to apply, etc., and achieve the effect of simple preparation process and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

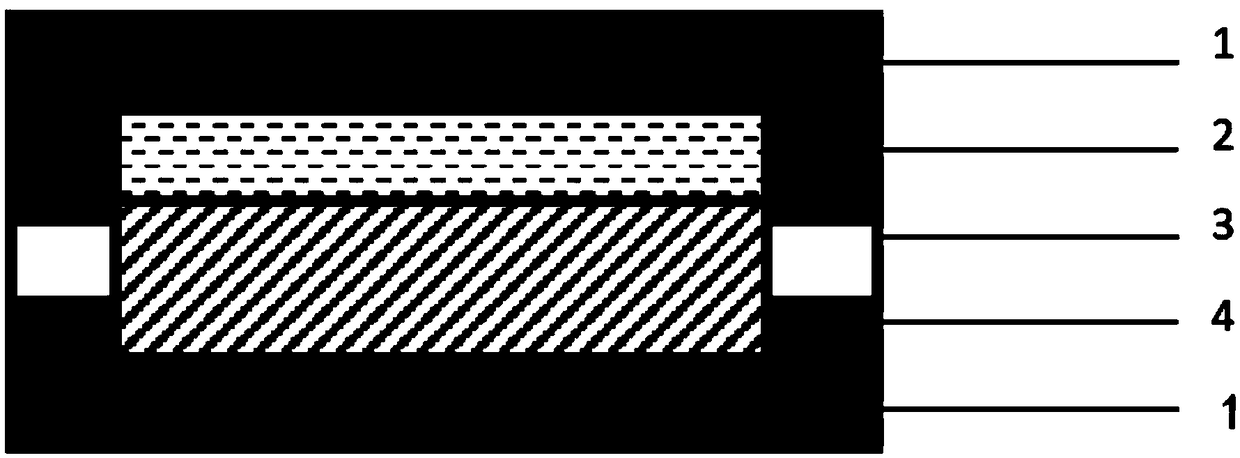

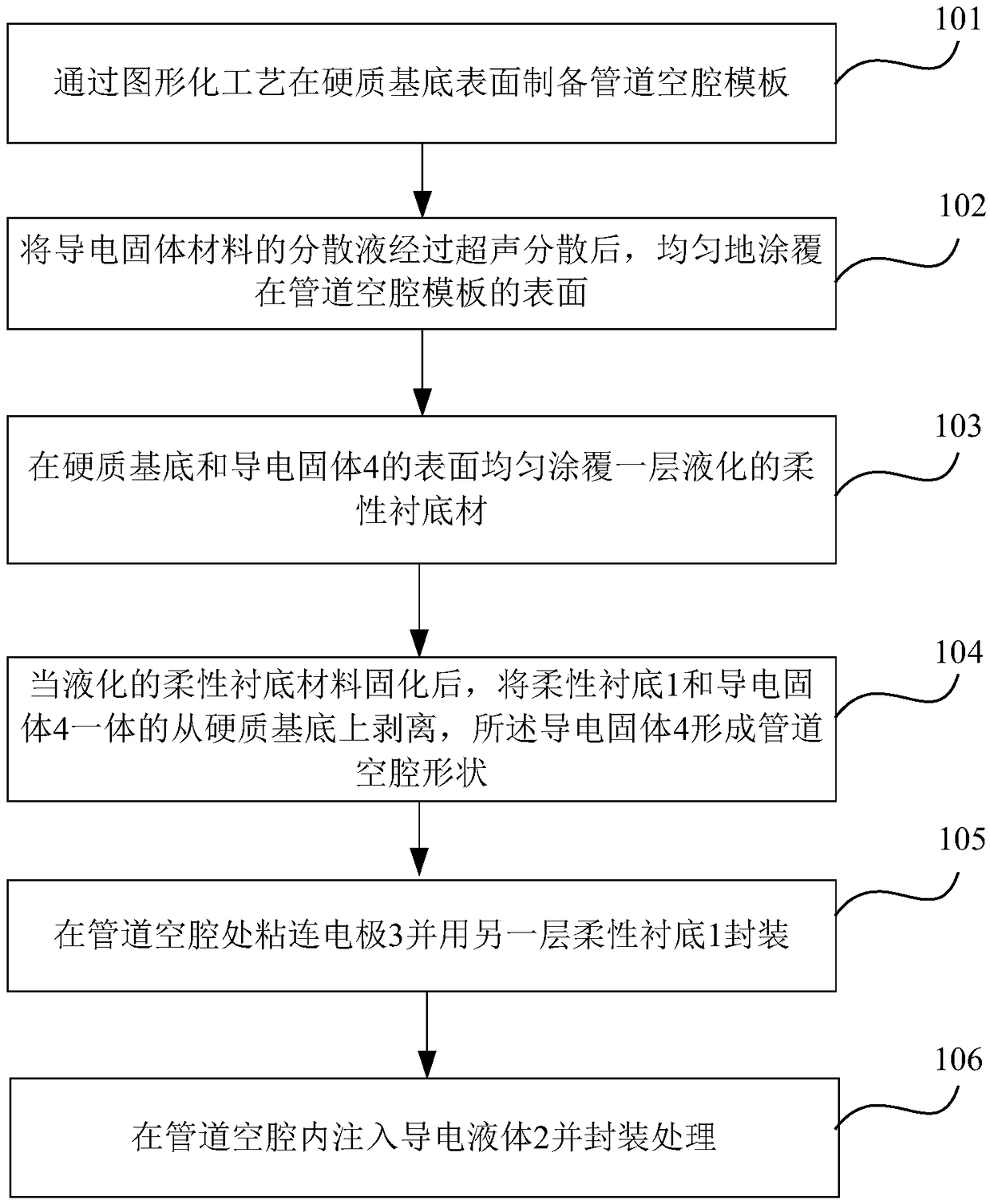

[0091] 1. Clean the glass sheet with clean ethanol, blow it dry with nitrogen, and paste the high temperature resistant tape at equal distances.

[0092] 2. After the nano-copper wire dissolved in isopropanol (IPA) is ultrasonically dispersed, use a dropper to absorb the dispersion solution and evenly drop it on the high-temperature resistant tape. When the board is heated at high temperature, the nano-copper wires intersect and fuse to form a conductive network.

[0093] 3. Evenly spin-coat liquid polydimethylsiloxane (PDMS) on the glass sheet, then place it on a hot plate and heat it to solidify, then peel it off from the glass sheet. The conductive network of nano-copper wires has been embedded on the surface of PDMS, and the A clear pipe cavity structure is formed at the copper wire.

[0094] 4. Apply silver glue on both sides of the nano-copper wire film layer, stick the wires and attach the top layer of PDMS.

[0095] 5. Inject the conductive liquid material PEDOT:PSS ...

Embodiment 2

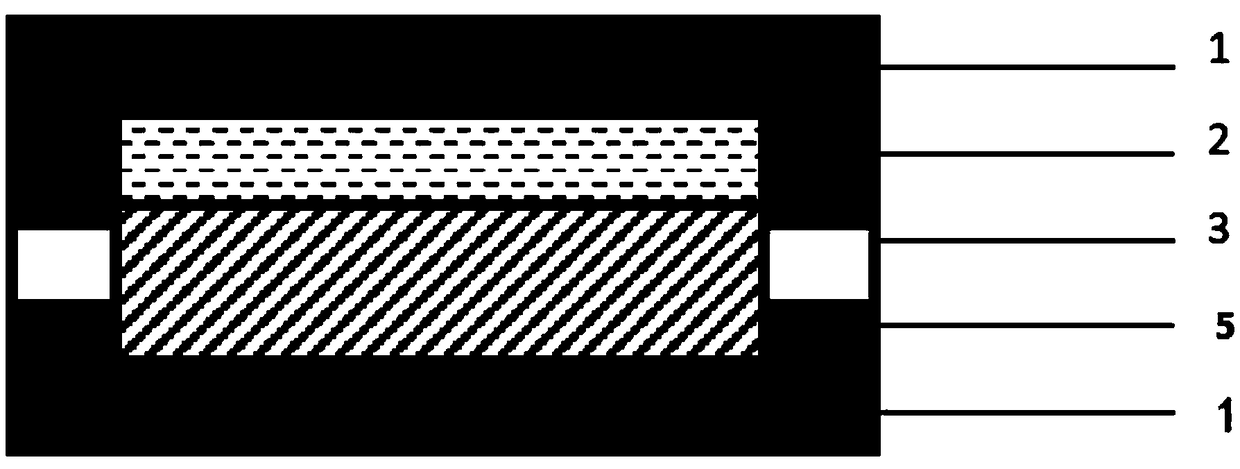

[0097] 1. Clean the glass sheet with clean ethanol, blow it dry with nitrogen, and paste the high temperature resistant tape at equal distances.

[0098] 2. After the nano-copper wire dissolved in IPA is ultrasonically dispersed, use a dropper to absorb the dispersion solution and evenly drop it on the high-temperature-resistant tape. After the IPA volatilizes, place the glass sheet on a hot plate in the glove box to heat at high temperature. The nano-copper wires intersect and fuse to form a conductive network.

[0099] 3. Evenly spin-coat platinum-catalyzed silicone rubber on the glass sheet. After curing at room temperature, peel it off from the glass sheet. The conductive network of nano-copper wires has been embedded on the surface of platinum-catalyzed silicone rubber, and an obvious pipeline cavity is formed at the nano-copper wire. structure.

[0100] 4. Apply silver glue on both sides of the nano-copper wire film layer, stick the wires and attach the top layer of pla...

Embodiment 3

[0103] 1. Clean the glass sheet with clean ethanol, blow it dry with nitrogen, and paste the high temperature resistant tape at equal distances.

[0104] 2. After ultrasonically dispersing the ethanol-soluble nano-copper wires, use a dropper to absorb the dispersion solution and evenly drop-coat it on the high-temperature-resistant tape. After the ethanol volatilizes, the nano-silver wires intersect and fuse to form a conductive network.

[0105] 3. Evenly spin-coat liquid PDMS on the glass sheet, then heat it on a hot plate until solidified, and peel it off the glass sheet. The nano-silver wire conductive network has been embedded on the PDMS surface and the nano-copper wire has formed an obvious pipeline cavity structure. Apply silver glue on both sides of the nano-silver wire film layer, glue the wires and attach the top layer of PDMS.

[0106] 4. The conductive liquid material PEDOT:PSS is injected into the cavity structure of the pipeline between the two layers of PDMS to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com