A kind of ultraviolet curing ink and preparation method thereof

A technology of ultraviolet light and production method, which is applied in the direction of ink, household utensils, applications, etc., can solve the problems of high ink cost, skin irritation, harmful to human body, etc., and achieve energy consumption saving, drying time reduction, and curing speed improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

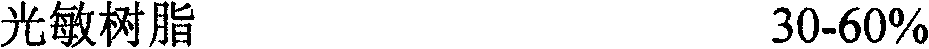

[0028] Prepare a kind of ultraviolet curable ink, the raw material composition composition of present embodiment is as follows:

[0029]

[0030]

[0031] Carry out the preparation of UV-curable ink according to above specific formula data, described photosensitive resin refers to the mixture of epoxy acrylic resin and urethane acrylate, and described epoxy acrylic resin refers to self-made epoxy acrylic resin, and its specific method is as follows:

[0032] Put epoxy resin E-44 into a reaction kettle with a reflux condenser, start stirring, add acrylic acid, hydroquinone, N, N'-dimethylbenzylamine in sequence, heat up, and feed carbon dioxide or Nitrogen protection. When the temperature rises to 70°C, stop heating, and the reactant starts to polymerize (exothermic reaction, the temperature rises automatically after stopping heating). When the temperature reaches 110°C, carefully control the reaction at 110°C for 2 hours, and take samples to measure the acid value (take ...

Embodiment 2

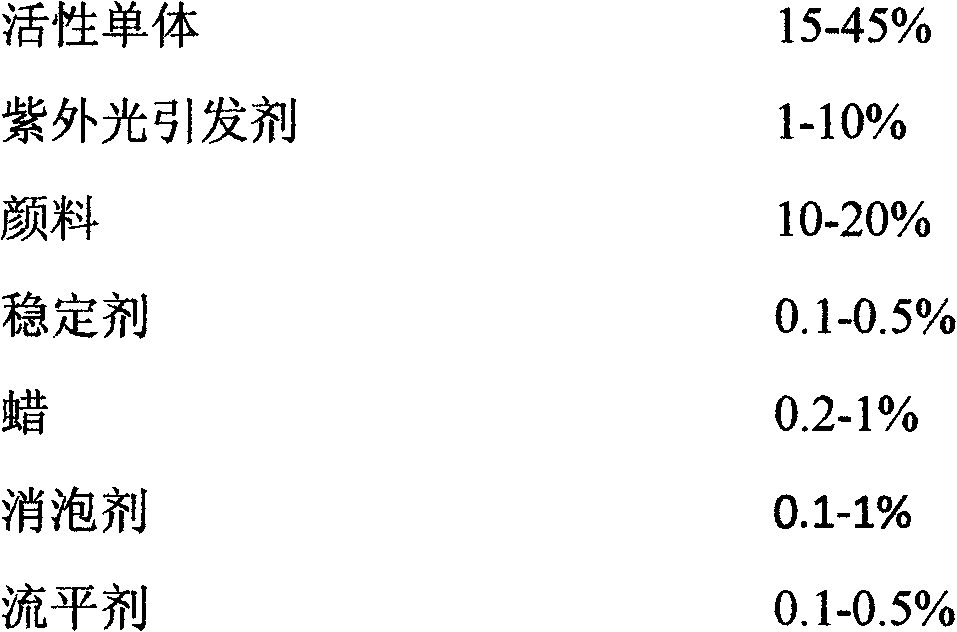

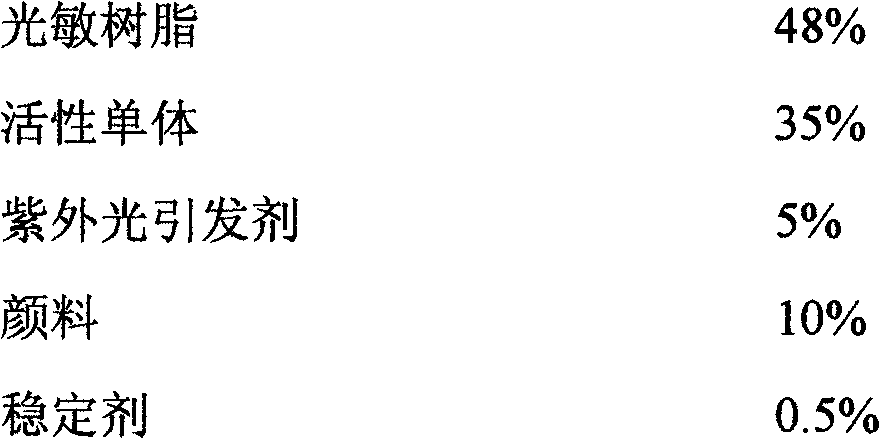

[0037] Prepare a kind of ultraviolet curable ink, the raw material composition composition of present embodiment is as follows:

[0038]

[0039]According to the above specific formula data, the preparation of UV-curable ink is carried out. The described photosensitive resin refers to the mixture of epoxy acrylic resin and polyurethane acrylate, and the described epoxy acrylic resin refers to difunctional aromatic epoxy acrylate oligomerization Matter UE-13; described urethane acrylate refers to aromatic urethane acrylate SU-710; described active monomer refers to dipentaerythritol hexaacrylate (DPHA) and tetrahydrofuryl methyl methacrylate (THFFA); described The ultraviolet photoinitiator refers to 2-phenylbenzyl-2-dimethylamine-1-(4-morpholine benzylphenyl) butanone; the described pigment refers to sunfast dark red; the described stabilizer refers to 2, 4,6-di-tert-butyl p-cresol; described wax refers to microcrystalline wax; described defoamer refers to a mixture of modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com