Curved substrate multi-phase micro-optical element processing method based on flexible ultraviolet die mold

A micro-optical and multi-phase technology, which is applied in the photoplate making process of optical elements, pattern surface, optics, etc., can solve the problems of inability to realize processing and limited application, and achieve easy batch and rapid processing, simple processing technology, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

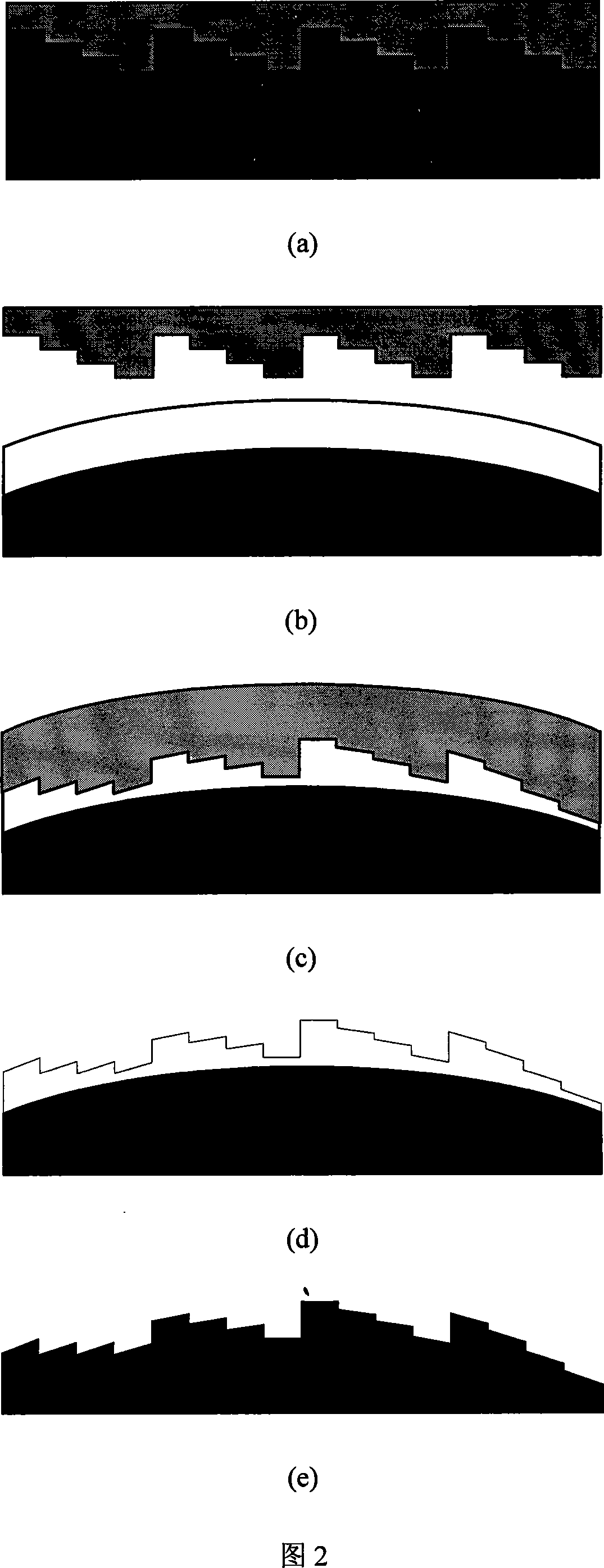

[0044] As shown in Figure 2, the diffractive optical lens with spherical base multi-step micro-relief structure is made, the element material is glass, the stamper material is PDMS, and the polymer required for UV imprinting is UV-curable glue OG154. The specific process is as follows:

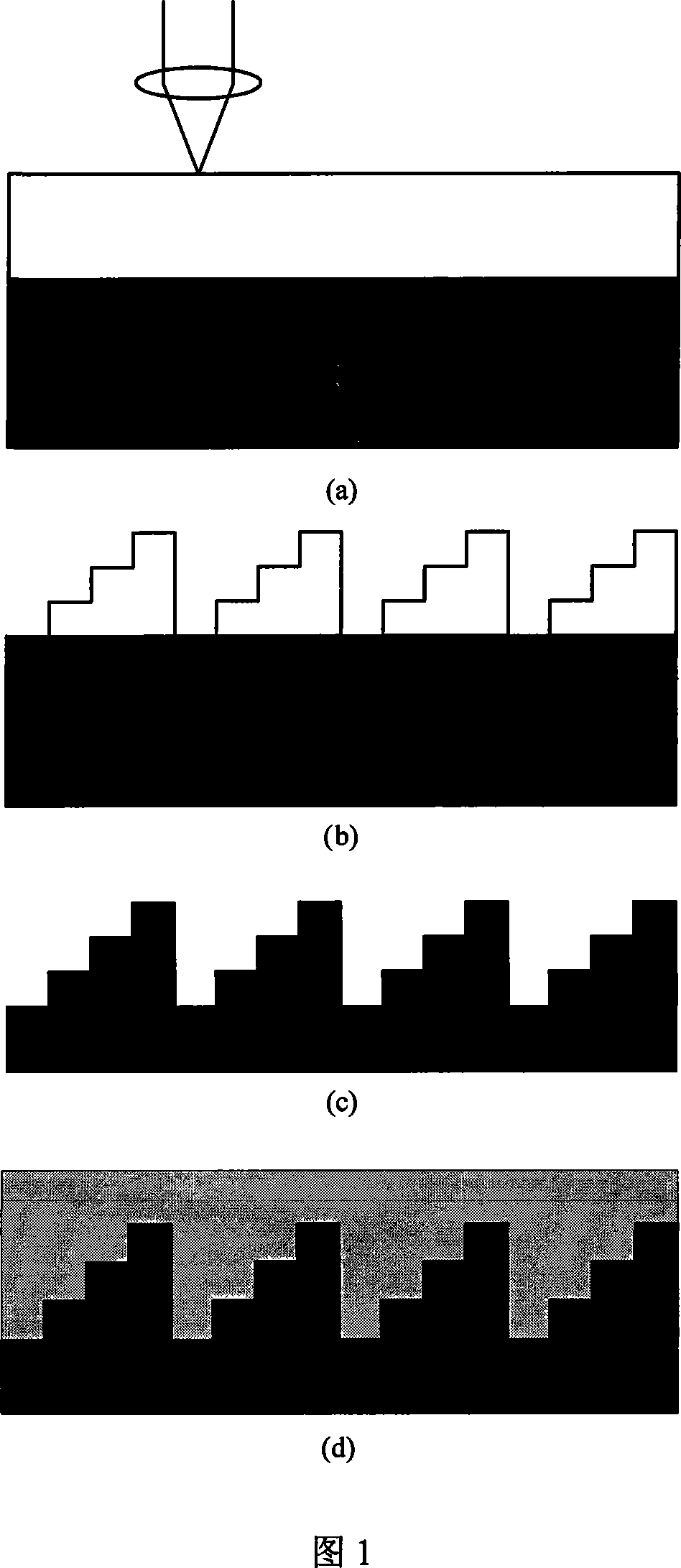

[0045] 1. As shown in Figure 1, laser direct writing technology is used to produce a surface relief quartz master with the same structure as the target.

[0046] 2. As shown in Figure 2(a), the microstructure injection molding replication technology is used to replicate the microstructure of the master plate to the surface of the PDMS material.

[0047]3. As shown in Figures 2(b) and 2(c), the PDMS stamper is used to carry out UV imprinting on the spherical substrate, and the PDMS stamper is bent into a curved surface similar to the processed spherical surface under the action of external force.

[0048] 4. As shown in Fig. 2(d), it is the spherical polymer micro-relief structure after demould...

Embodiment 2

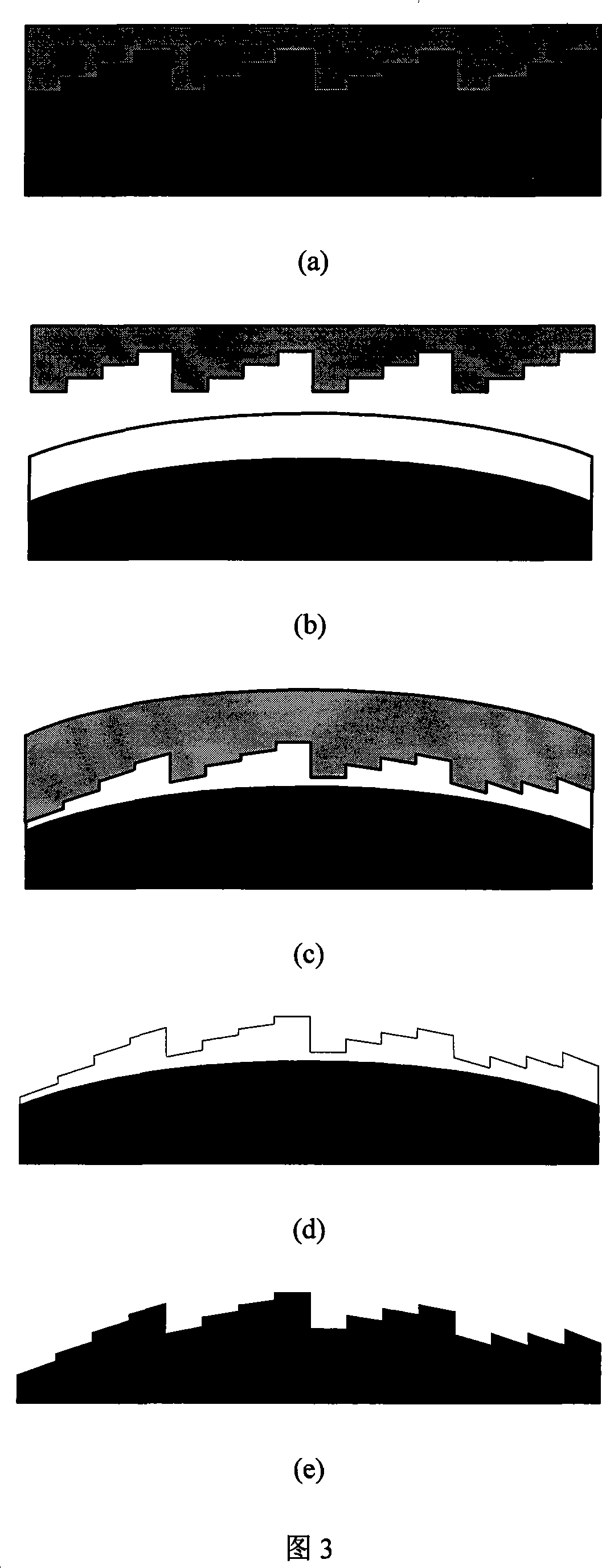

[0051] As shown in Figure 3, a binary optical element with a multi-step structure on a cylindrical base is fabricated. The material of the element is single crystal silicon, the material of the mold is PDMS, and the polymer is an ultraviolet organic photosensitive solvent PAK01. The specific process is as follows:

[0052] 1. As shown in Figure 1, apply electron beam direct writing technology to make a quartz mother board with the same structure as the target.

[0053] 2. As shown in Figure 3(a), the microstructure of the master plate is copied to the surface of the PDMS material by using the microstructure injection molding replication technology.

[0054] 3. As shown in Figure 3(b) and 3(c), apply the PDMS stamper to implement UV imprinting on the cylindrical substrate, and the PDMS stamper is bent into a curved surface similar to the processed cylindrical surface under the action of external force shape.

[0055] 4. As shown in Fig. 3(d), it is the columnar-based polymer ...

Embodiment 3

[0058] As shown in Figure 4, the Fresnel lens with a continuous relief structure is produced, the element material is sapphire, the molding material is PDMS, and the polymer is selected from the ultraviolet organic photosensitive solvent PAK01. The specific process is as follows:

[0059] 1. As shown in Figure 1, apply the electron beam direct writing technology to make a continuous relief structure quartz mother board with the same structure as the target.

[0060] 2. As shown in Figure 4(a), the microstructure injection molding replication technology is used to replicate the microstructure of the master plate to the surface of the PDMS material.

[0061] 3. As shown in Figure 4(b) and 4(c), the PDMS stamper is used to implement UV imprinting on the aspheric substrate, and the PDMS stamper is bent into a curved shape similar to the processed aspheric surface under the action of external force appearance.

[0062] 4. As shown in Figure 4(d), it is the aspherical polymer micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com