Scribing wheel and method for scribing brittle material substrate

A scribing wheel, ceramic substrate technology, applied in the direction of stone processing tools, stone processing equipment, fine working devices, etc., can solve the problems of low productivity, high operating costs, cutting edge wear, etc. rate improvement, production cost reduction, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Although the scribing wheel of the present invention will be described in more detail below, the present invention is not limited to these embodiments.

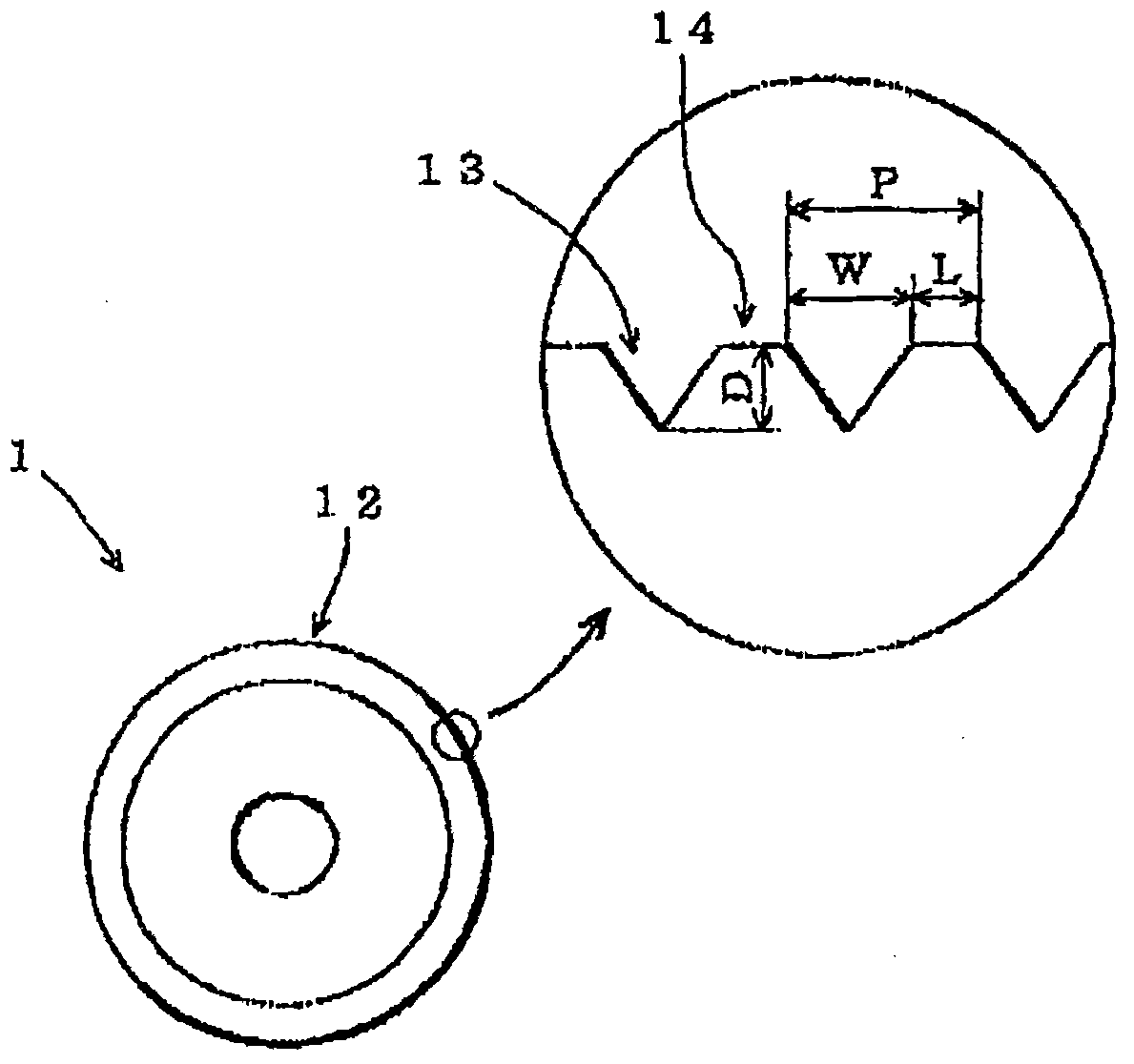

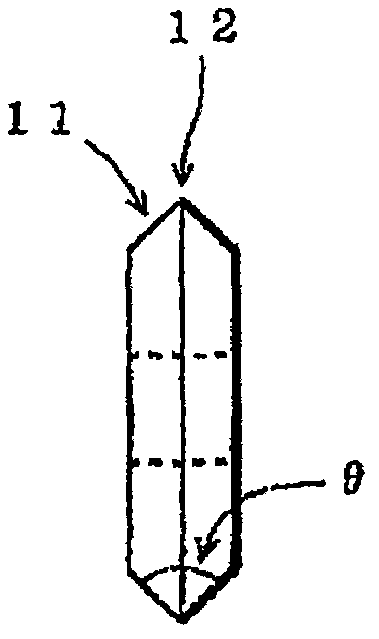

[0051] figure 1 and figure 2 One embodiment of the scribing wheel of the present invention is shown. figure 1 is the front view seen from the direction of the axis of rotation of the marking wheel, figure 2 for side view. Such as figure 2 As shown, a blade 11 having a substantially V-shaped cross section is formed on the peripheral portion of the disk-shaped wheel.

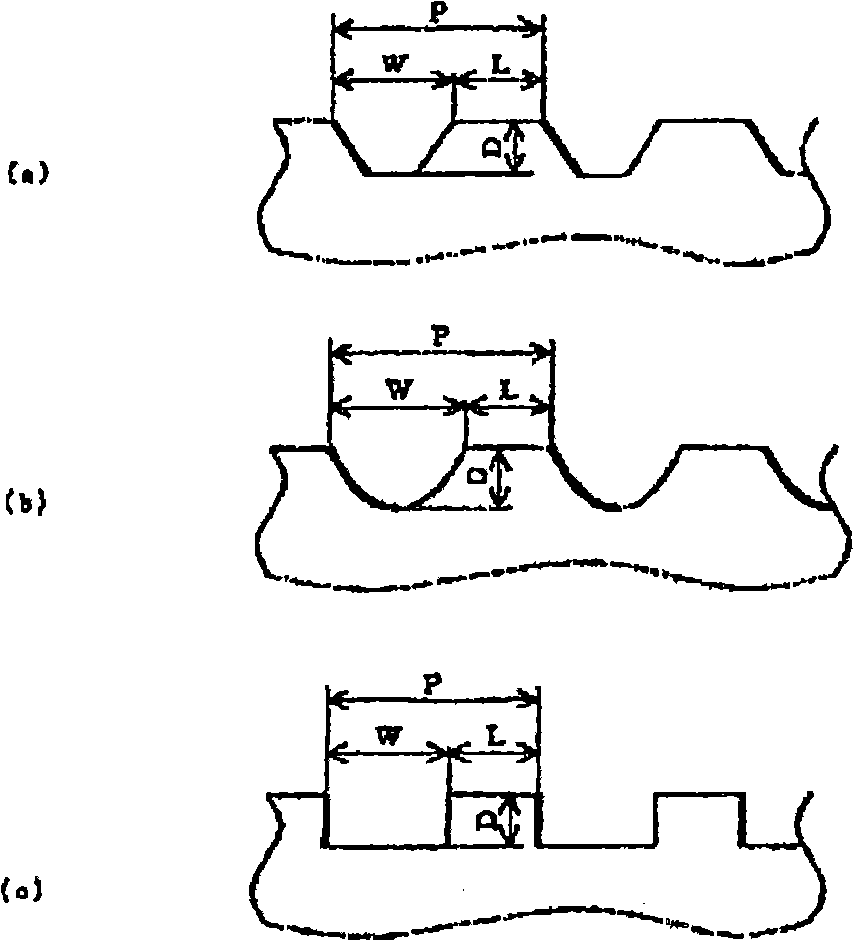

[0052] The front edge angle θ of the blade 11 is usually an obtuse angle, and the specific angle is appropriately set according to the material or thickness of the substrate to be cut, but is usually in the range of 90 to 160 degrees (for example, 100 to 140 degrees). In addition, if figure 1 As shown, a plurality of V-shaped grooves 13 are formed at predetermined intervals on the ridge line of the blade 11 , that is, the blade leading edge 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com