Nickel manganin gallium high-temperature shape memory alloy and method for making same

A technology of memory alloy and copper gallium, which is applied in the field of alloys and can solve problems such as the impossibility of cold and hot processing of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

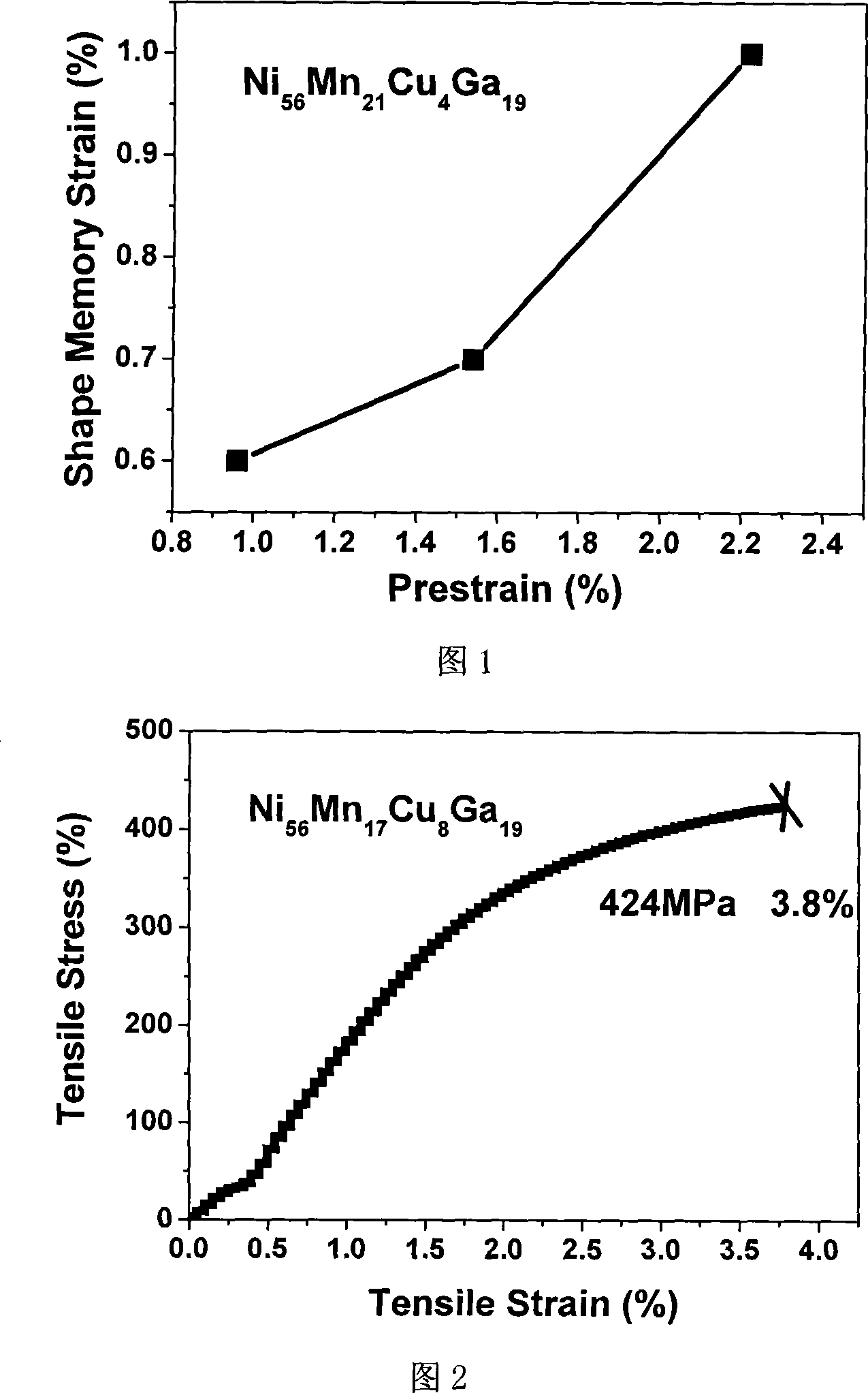

[0019] Embodiment 1: prepare Ni 56 mn 21 Cu 4 Ga 19 hot rolled sheet

[0020] Weigh 56% of nickel with a purity of 99.9%, 21% of manganese with a purity of 99.5%, 4% of copper with a purity of 99.9% and 19% of gallium with a purity of 99.99%; put the above nickel, manganese, copper and gallium raw materials into In the non-consumable vacuum electric arc furnace, vacuumize to 5×10 -3 Pa, filled with high-purity argon to 0.7×10 5 Pa, then repeated smelting at 1900°C for 4 times to obtain a NiMnCuGa high temperature shape memory alloy ingot; put the NiMnCuGa high temperature alloy ingot prepared above into a vacuum heat treatment furnace for heat treatment, and the vacuum degree was 5×10 -3 Pa, heat treatment temperature at 900°C for more than 24 hours, then cool with the furnace; hot-roll the above-mentioned heat-treated NiMnCuGa superalloy ingot at 950°C, and slowly hot-roll the alloy ingot into a sheet with a thickness of 0.5mm Alloy material; cut the alloy sheet obtaine...

Embodiment 2

[0022] Embodiment 2: prepare Ni 56 mn 17 Cu 8 Ga 19 hot rolled sheet

[0023] Weigh 56% of nickel with a purity of 99.9%, 17% of manganese with a purity of 99.5%, 8% of copper with a purity of 99.9% and 19% of gallium with a purity of 99.99%; put the above nickel, manganese, copper and gallium raw materials into In the non-consumable vacuum electric arc furnace, vacuumize to 6×10 -3 Pa, filled with high-purity argon to 0.5×10 5Pa, and then repeated smelting at 2000°C for 5 times to obtain a NiMnCuGa high-temperature shape memory alloy ingot; the above-mentioned NiMnCuGa high-temperature shape memory alloy ingot was put into a vacuum heat treatment furnace for heat treatment, and the vacuum degree was 5×10 -3 Pa, after heat treatment at 850°C for 24 hours, then cool in the furnace; hot-roll the above-mentioned heat-treated NiMnCuGa superalloy ingot at 850°C, and slowly hot-roll the alloy ingot into a sheet with a thickness of 0.8mm Alloy material; the alloy sheet obtained...

Embodiment 3

[0025] Embodiment 3: prepare Ni 50 mn 17 Cu 8 Ga 25 hot rolled sheet

[0026] Weigh 50% of nickel with a purity of 99.9%, 17% of manganese with a purity of 99.5%, 8% of copper with a purity of 99.9% and 25% of gallium with a purity of 99.99%; put the above nickel, manganese, copper and gallium raw materials into In the non-consumable vacuum electric arc furnace, vacuumize to 5×10 -3 Pa, filled with high-purity argon to 0.6×10 5 Pa, then repeated smelting at 1800°C for 5 times to obtain a NiMnCuGa high temperature shape memory alloy ingot; put the NiMnCuGa high temperature alloy ingot prepared above into a vacuum heat treatment furnace for heat treatment, and the vacuum degree was 4×10 -3 Pa, heat treatment temperature at 850°C for 72 hours, and cool with the furnace; cut the alloy sheet obtained above into small pieces by wire cutting method, put it in the heat treatment furnace, keep it at 850°C for 30min, and then quickly ice water Quenching is to obtain the sample for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com