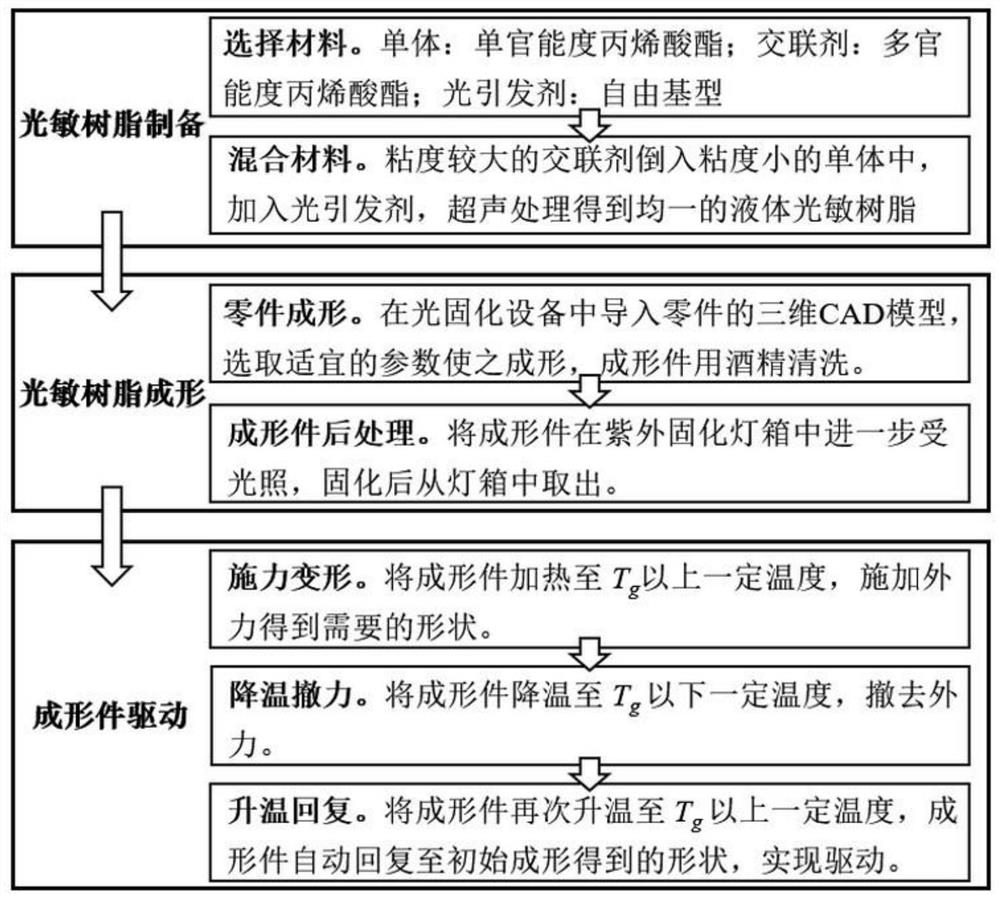

A photosensitive resin preparation, shaping and driving method for 4D printing

A photosensitive resin, 4D technology, used in manufacturing tools, additive manufacturing, manufacturing auxiliary devices, etc., can solve problems such as low curing rate, and achieve improved processing efficiency, short design and manufacturing cycle, excellent shape fixation rate and shape recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

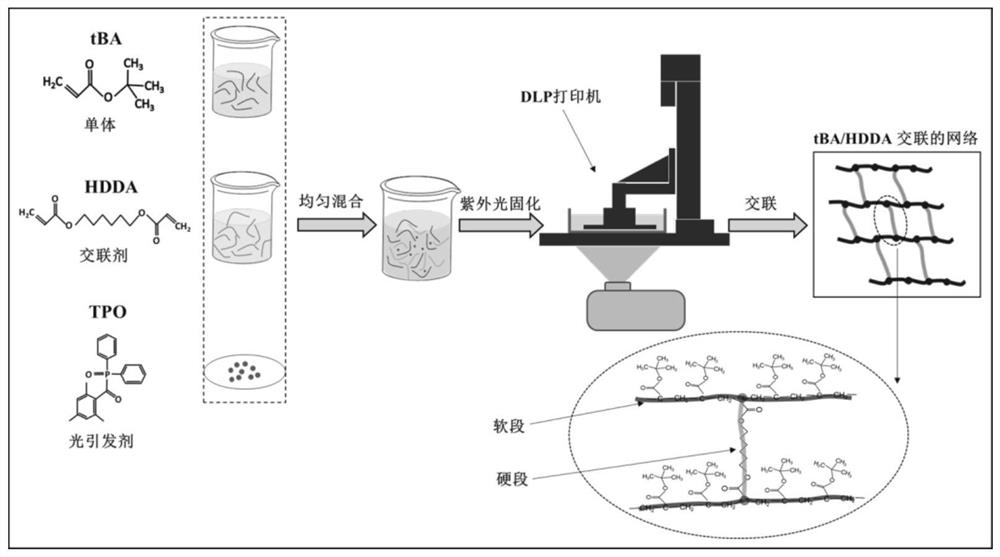

[0061] (1) Select 90g of tert-butyl acrylate as the monomer of photosensitive resin, 10g of 1,6-hexanediol diacrylate as the crosslinking agent of photosensitive resin, bis(2,4,6-trimethylbenzoyl) 1 g of phosphine oxide was used as photoinitiator. The three were mixed together and subjected to ultrasonic treatment for 10 min until a colorless and transparent liquid was formed.

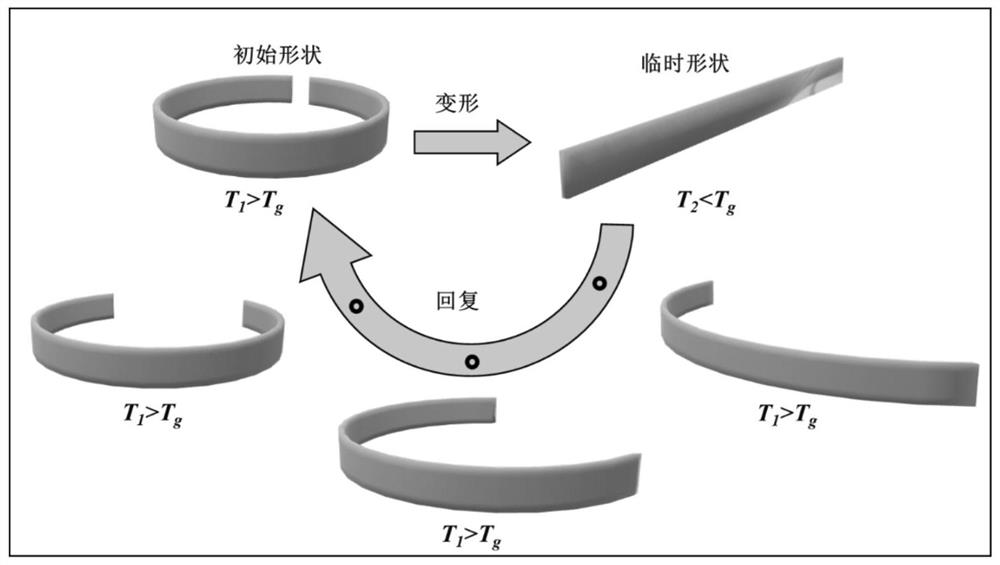

[0062] (2) Slowly pour the configured photosensitive resin into the resin tank of the photocuring equipment, and import the three-dimensional CAD model into the DLP equipment, that is, a ring with a gap, such as image 3 As shown, make it into shape, the forming parameters are set to 20 μm for each curing layer, and the curing time for each layer is 5s. After forming, soak the formed part with alcohol for 5 minutes, so as to clean the residual resin on the surface of the formed part;

[0063] (3) Post-processing of the formed part: the formed part is further exposed to light for 20 minutes in an ultra...

Embodiment 2

[0066] (1) Choose 80g of isobornyl acrylate as the monomer of photosensitive resin, 20g of 1,6-hexanediol dimethacrylate as the crosslinking agent of photosensitive resin, bis(2,4,6-trimethylbenzene Formyl) phenyl phosphine oxide 1g was used as photoinitiator. The three were mixed together and subjected to ultrasonic treatment for 10 minutes until a colorless and transparent liquid was formed to obtain a photosensitive resin.

[0067] (2) Slowly pour the configured photosensitive resin into the resin tank of the photocuring equipment, and import the 3D CAD model into the DLP equipment to form it. The forming parameters are set to 50 μm for each curing layer, and the curing time for each layer is 8s. After forming, soak the formed part with alcohol for 5 minutes, so as to clean off the residual photosensitive resin on the surface of the formed part;

[0068] (3) Post-processing of the formed part: the formed part is further exposed to light for 20 minutes in an ultraviolet cur...

Embodiment 3

[0071] (1) Select 70g of β-hydroxyethyl acrylate as the monomer of photosensitive resin, 30g of polyethylene glycol dimethacrylate as the crosslinking agent of photosensitive resin, 1g of α, α-diethoxyacetophenone as photoinitiator. The three were mixed together and subjected to ultrasonic treatment for 10 min until a colorless and transparent liquid was formed.

[0072] (2) Slowly pour the prepared photosensitive resin into the resin tank of the photocuring equipment, and import the 3D CAD model into the DLP equipment to form it. The forming parameters are set to 100 μm for each curing layer, and the curing time for each layer is 8s. After forming, soak the formed part with alcohol for 5 minutes, so as to clean off the residual photosensitive resin on the surface of the formed part;

[0073] (3) Post-processing of the formed part: the formed part is further exposed to light for 18 minutes in an ultraviolet curing light box to cure the uncured photosensitive resin inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com