Method for producing hot strip with a multiphase structure

A hot-rolled strip, controlled technology, applied in the field of hot-rolled strip with multiphase structure, can solve the problems of troublesome cost, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

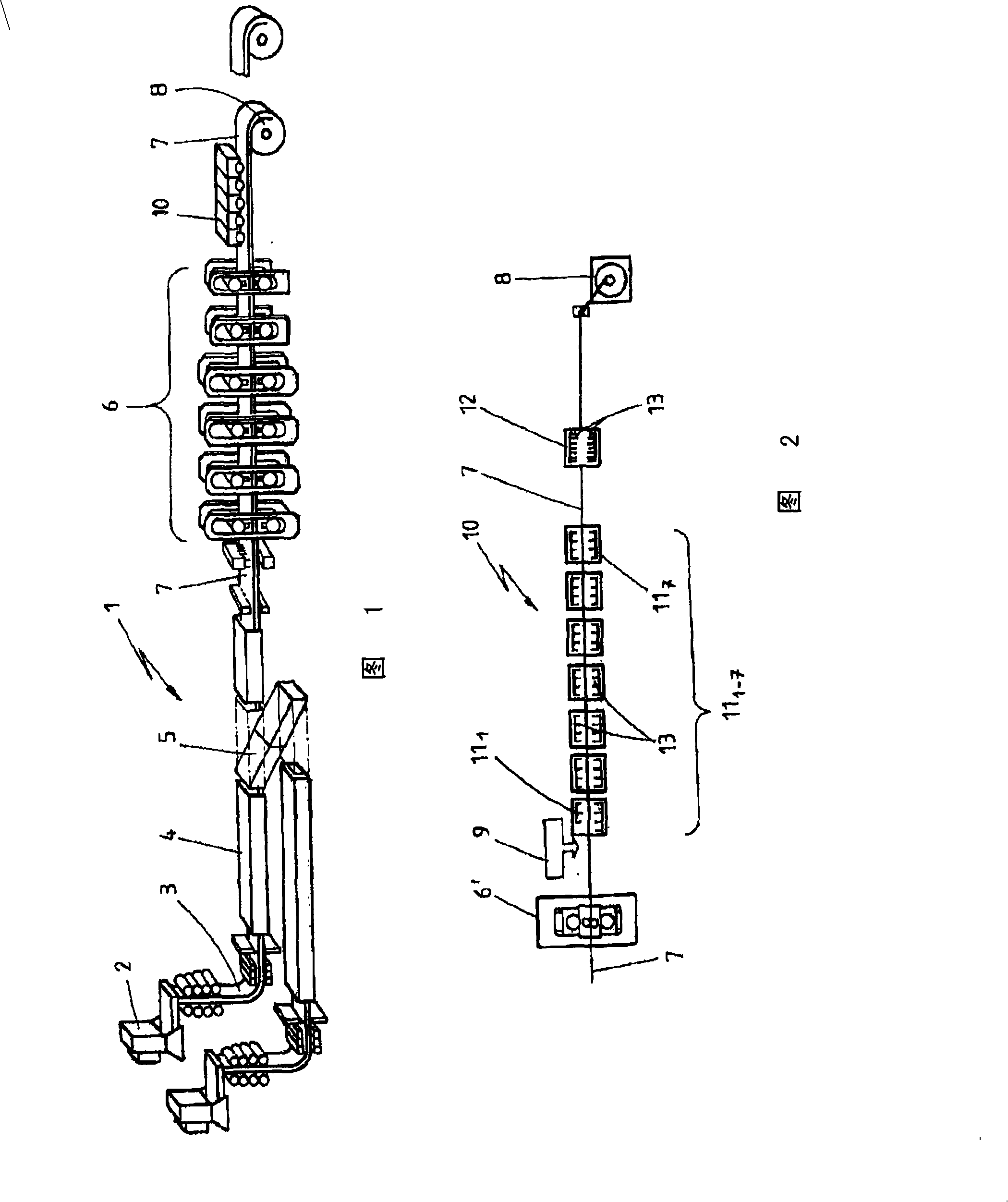

[0024] FIG. 1 schematically shows the layout of a conventional CSP-device 1 . In the embodiment shown, the plant 1 comprises the following main components in the conveying direction (from left to right in the figure), namely a pouring plant with two strands 2 , strand guide rolls 3 , a furnace with furnace pendulum device ( ) of the soaking furnace 4, the multi-stand rolling line 6, the cooling section 10 and the coiler 8.

[0025] FIG. 2 shows a modified cooling section 10 of the CSP plant 1 , which is required here for carrying out the cooling process according to the invention and which is already described in EP 1 108 for the production of dual-phase steels. 072 B1 is made public. This modified cooling section 10 of the CSP plant 1, which is arranged behind the last finishing stand 6', has a plurality of adjustable water cooling zones 11 with water jets 13 arranged one after the other at a certain distance. 1-7 , 12 , spray the upper side surface and the lower side sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com