Detection method of semiconductor laser degradation mechanism

A detection method and laser technology, applied in the direction of single semiconductor device testing, etc., can solve the problems of high economic cost, low efficiency, long time consumption, etc., and achieve the effect of prolonging the working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

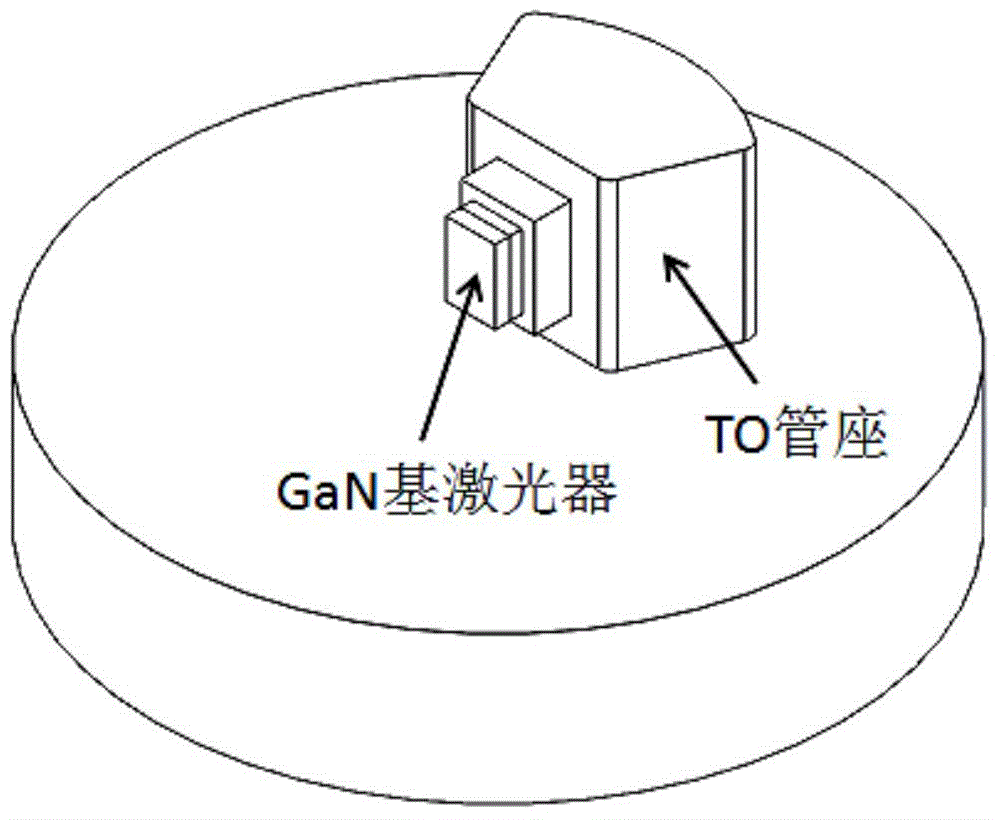

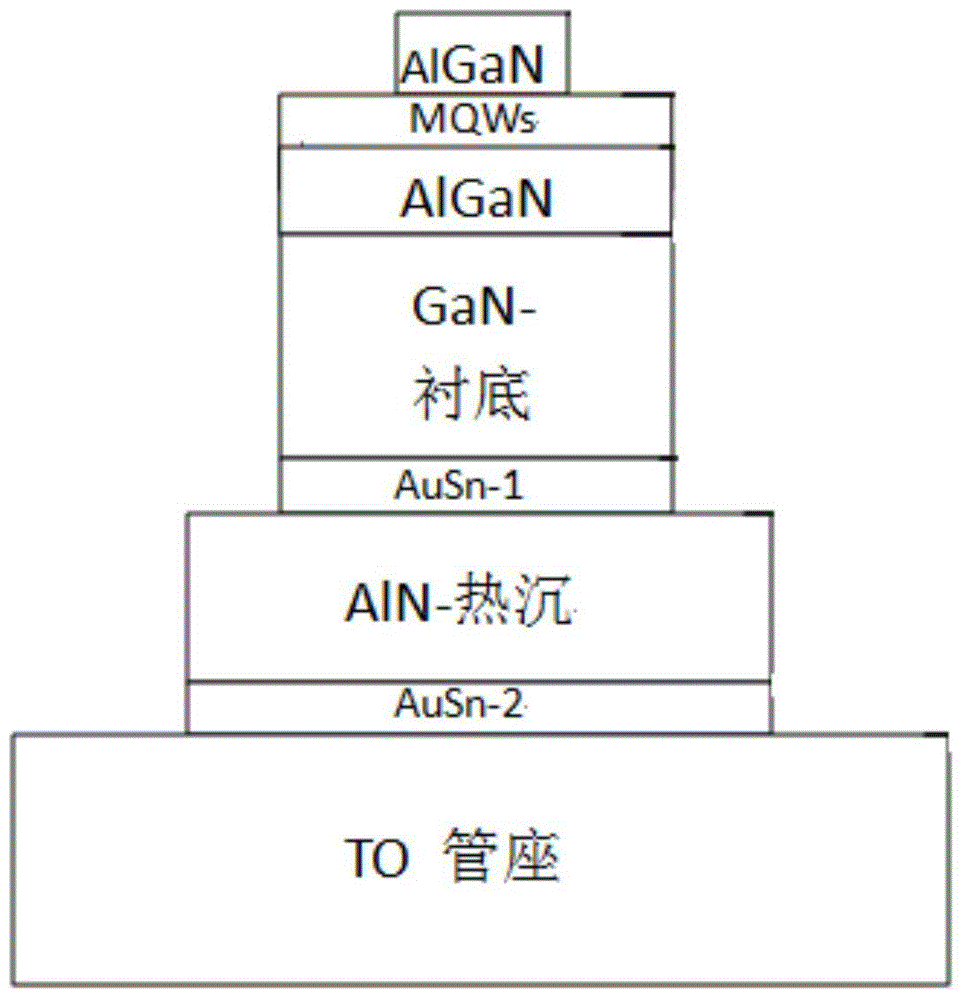

[0043] Embodiment 1: This embodiment takes a GaN-based semiconductor laser as an example (see Figure 1a Schematic diagram of the structure of GaN-based lasers packaged in TO, Figure 1b It is a schematic diagram of a GaN-based laser including a chip structure), this embodiment uses the forward voltage method to measure the relationship of the voltage of the semiconductor laser with time. According to the relationship between the voltage and temperature of the GaN-based semiconductor laser, the measured voltage-time relationship is converted into a temperature-time relationship.

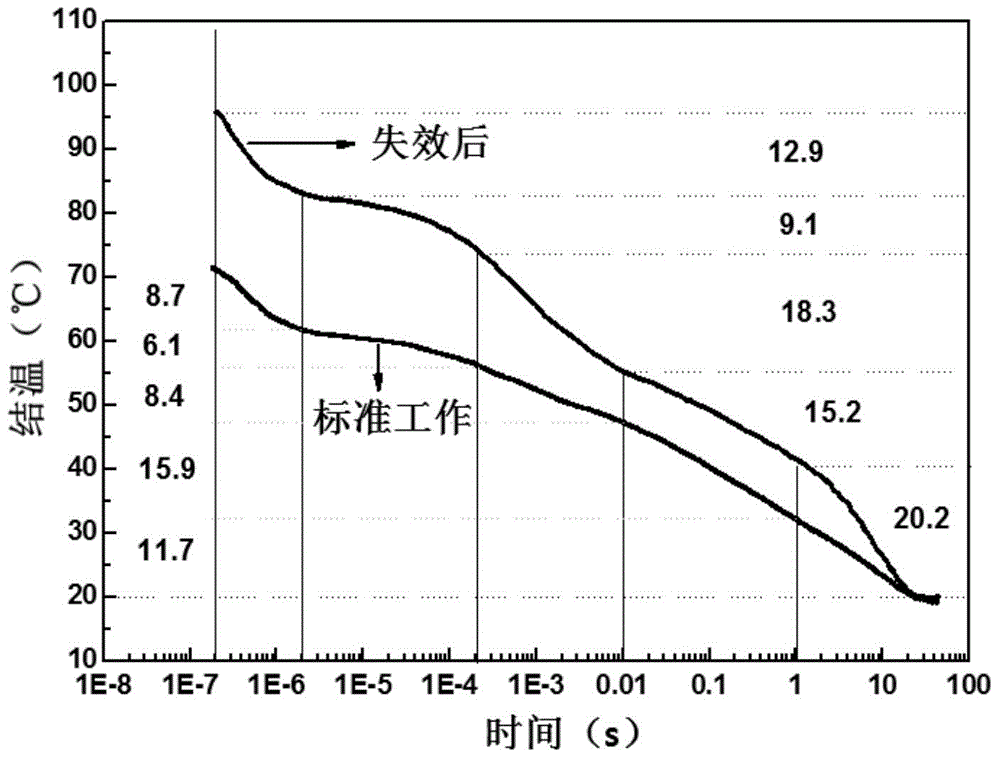

[0044] The transient cooling curves of the standard working GaN-based semiconductor laser and the failed GaN-based semiconductor laser are respectively measured according to the following methods.

[0045]The semiconductor laser is heated under the operating current for 10 minutes, and when the semiconductor laser reaches a thermally stable state, the working current is turned off and the voltage of...

Embodiment 2

[0047] Embodiment 2: This embodiment takes a GaN-based semiconductor laser as an example. In this embodiment, a forward voltage method is used to measure the relationship of the voltage of the semiconductor laser with time. According to the relationship between the voltage and temperature of the GaN-based semiconductor laser, the measured voltage-time relationship is converted into a temperature-time relationship.

[0048] The transient cooling curves of the standard working GaN-based semiconductor laser and the failed GaN-based semiconductor laser are respectively measured according to the following methods.

[0049] Heat the standard working semiconductor laser under the working current for 10 minutes until the semiconductor laser reaches thermal stability. Turn off the high working current and measure the voltage of the GaN-based semiconductor laser as a function of time at a small current of 1mA; then convert the voltage-time curve into a temperature- Time curve; draw the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com