Method for drying carbon anode roasting furnace

A carbon anode and roasting furnace technology, which is applied in the field of aluminum electrolytic carbon anode roasting furnace, can solve problems such as troublesome and long baking time, achieve the effects of optimizing process parameters, short baking time, and reducing the cost of baking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

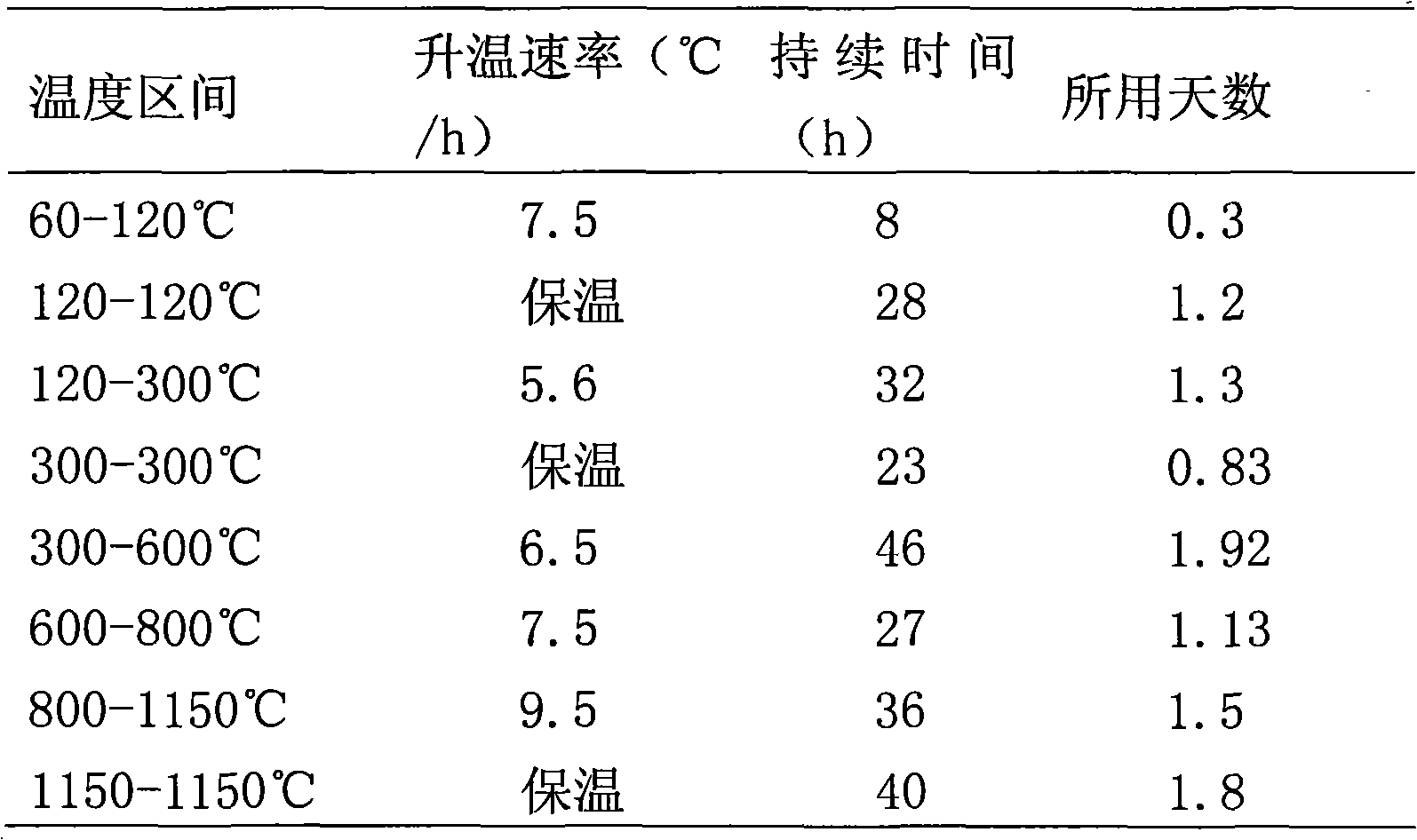

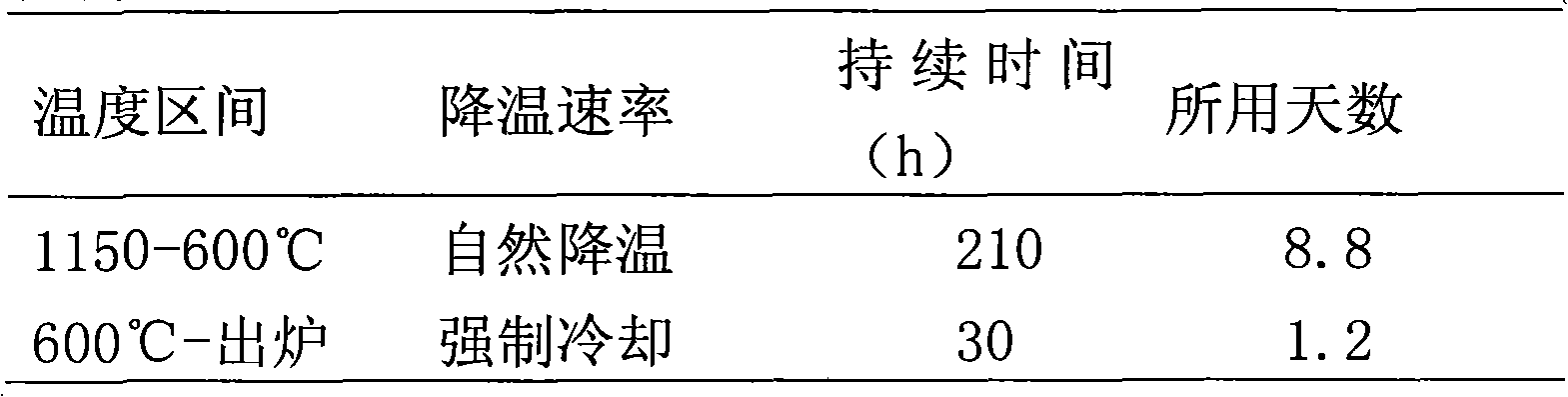

[0020] The invention discloses a method for baking a carbon anode roaster. The roaster chamber is an annular open roaster with 38 chambers, which uses natural gas as fuel, and the roaster adopts two flame systems.

[0021] The specific furnace loading requirements for the roasting furnace are as follows: 1# and 21# furnace chambers are filled with raw blocks and sealed furnace chambers, 2# and 22# furnace chambers are filled with waste raw blocks, and from 3# and 23# furnace chambers are loaded with qualified raw blocks. The furnace room guarantees one out, one in, and one in preparation. The combustion rack is placed in the 2# and 22# furnace chambers 2 and 4 observation holes, and the smoke exhaust rack is placed in the 4# and 23# furnace chambers. Ignite from the observation hole of 2# and 22# furnace chamber 2. After 3 flame movement cycles, move the smoke exhaust rack to add the 4th furnace chamber, and confirm whether to ignite the second row of nozzles according to whet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com